Wurtsmith AFB: Evaluating Cost, Energy, and Waste Management for PFAS Groundwater Containment Options

A look at two PFAS cleanup approaches reveals how choosing the right technology can slash costs and shrink environmental impact

As the Department of Defense (DoD) faces a projected $9 billion and rising price tag for cleaning up per- and polyfluoroalkyl substances (PFAS) contamination at military installations, Congress has mandated that the DOD prioritize “…technologies that eliminate the PFAS risk to human health and the environment in the most cost-effective and energy-efficient manner.” (US Congress, 2023, p. 59).

One case study, from the former Wurtsmith Air Force Base (AFB) in Oscoda, Michigan, provides an instructive comparison between a conventional pump-and-treat (P&T) system and in situ colloidal activated carbon (CAC) barriers.

While P&T remains the familiar go-to strategy for groundwater containment, recent analyses show that in situ CAC barriers can offer substantial benefits in containing PFAS—both in financial terms and in environmental impact. The Wurtsmith comparison reveals the long-term implications in and makes a compelling case for considering CAC more broadly across similar DOD sites.

The Wurtsmith Case: Background and Remedial Context

Like many other decommissioned military facilities, Wurtsmith AFB has extensive legacy contamination from AFFF used in firefighting training exercises. PFAS in these foams have leached through soil into the aquifer, forming a persistent groundwater plume that migrated to surface water. Due to PFAS detected in fish-tissue samples, 'do not eat fish' advisories have been issued for the area (MDHHS, 2012; MDHHS, 2019).

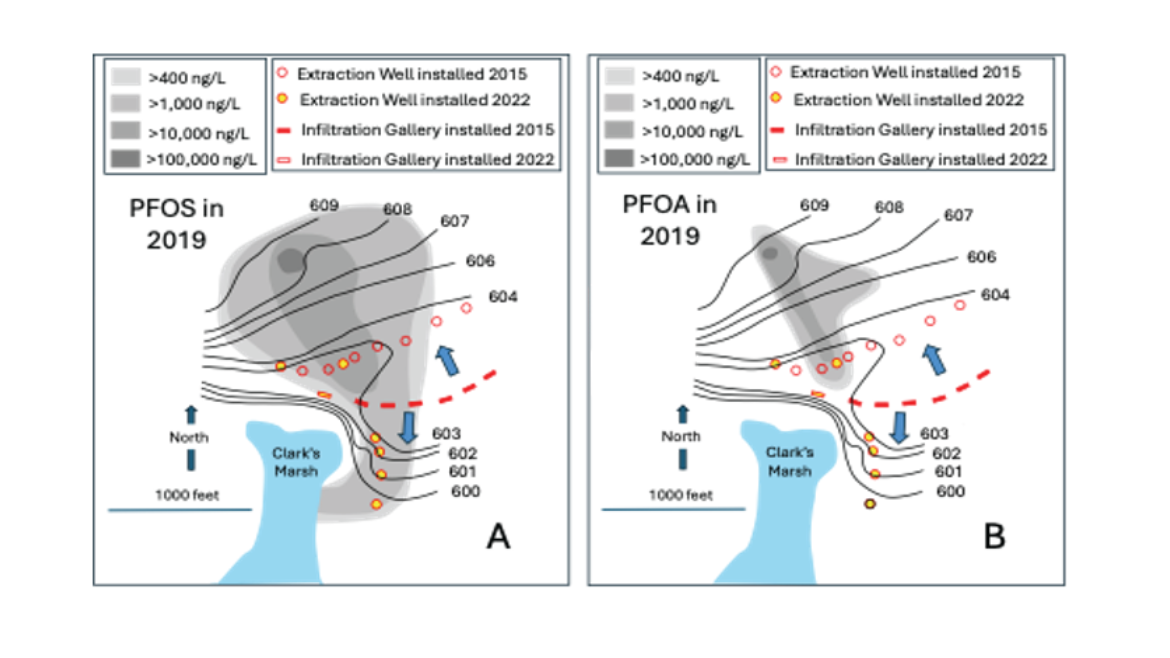

To minimize plume impacts on surface water, a P&T system was installed to extract and treat PFAS-contaminated groundwater. The system is designed to provide hydraulic control of the plume, pumping PFAS-impacted groundwater through a granular activated carbon (GAC) filtration unit at a rate of 445 gallons per minute (GPM) or more than 200 million gallons per year. The system layout is depicted on Figure 1.

REDRAWN: Figure 1: Comparison of the distribution of extraction wells installed in 2022 to the distribution of wells installed in 2015 and to the distribution of PFOS (Panel A) and PFOA (Panel B) in the plume. Distribution PFOS and PFOA redrawn from Figure 2-6 and 2-7 of Bay West (2022). Groundwater elevations April 2021 redrawn from Figure 6 of USAF (2021). Elevations in feet asl. (Birnstingl and Wilson, 2024) Note: the clean-up targets of 4 ng/L are 100 x lower than the minimum concentrations illustrated in the figure.

While the P&T system provides effective containment, its high operational costs and energy use over time invite a direct comparison with the other leading technology for PFAS groundwater remediation: in situ CAC barriers.

Cost Comparison: P&T vs. In Situ CAC Barrier

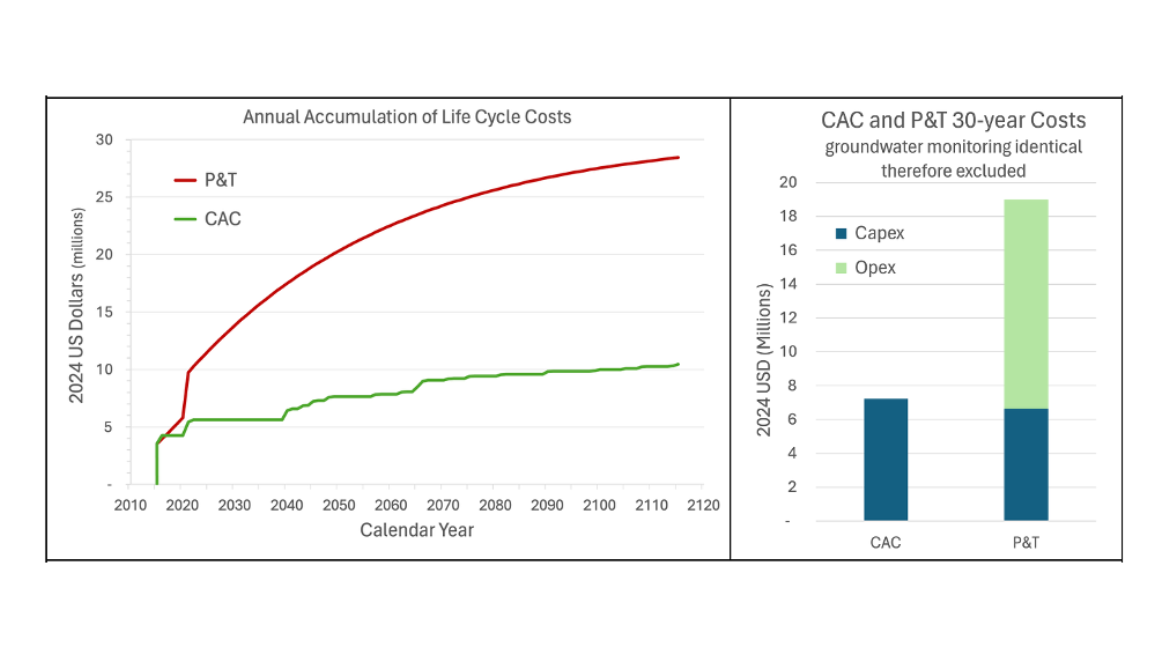

In a detailed financial analysis published in Remediation (Birnstingl & Wilson, 2024), the Wurtsmith P&T system’s full lifecycle cost was estimated at more than $19 million over a 30-year period (in 2024-dollar value). This figure includes capital expenditures (CAPEX), ongoing operation and maintenance (OPEX), and waste management.

By comparison, a hypothetical in situ CAC barrier designed to achieve similar containment objectives was projected to cost approximately $7.2 million over the same period—a savings of over 60% (Figure 2). Notably, both approaches shared similar upfront capital costs, but diverged sharply in ongoing operating expenses.

The stark difference stems from the passive nature of CAC. Once installed, the CAC barrier requires no pumps, no power, and no aboveground infrastructure. The carbon remains in place, sorbing PFAS as groundwater flows through, with no energy input and no waste generation.

AIR FORCE: Figure 2: Total accumulation and life cycle costs for remedial options. Wurtsmith Air Force Base. Discounted Present Value (2.5%), 2024 USD, 2015-2115. (Birnstingl and Wilson, 2024).

Performance and Longevity

The CAC barrier works by injecting a proprietary formulation of micron-scale activated carbon particles suspended in liquid. These particles adhere to the aquifer matrix, creating a high-efficiency belowground filter that captures dissolved PFAS compounds as groundwater passes through.

Barrier longevity is determined by the dose of carbon applied relative to the mass flux of PFAS in the plume. At typical field concentrations, projected service lives of multiple decades or longer are the norm (Carey et al., 2019; 2022; Newell, et al. 2025). Should PFAS mass flux persist beyond this timeframe, the barrier can be rejuvenated with additional injections.

In the Wurtsmith analysis, the CAC design assumed a conservative carbon dose, yielding cost estimates that may be further optimized with field data. Still, even under cautious assumptions, the CAC alternative delivered a significantly lower total cost of ownership.

Waste and Energy

One of the biggest liabilities associated with P&T systems is their continual generation of secondary PFAS waste streams. Extracted water must be treated using GAC, as at Wurtsmith AFB, or resin-based systems. The spent media must then be handled, replaced, and ultimately disposed of. This creates additional pathways for potential environmental release, a concern highlighted in Hall et al. (2024). The CAC barrier, in contrast, does not generate waste. Further, since CAC barriers require no energy to function, they uphold the Congressional directive to prioritize energy-efficient solutions for eliminating PFAS risk.

EPA Flags PFAS Waste Risks

Disposal Warning from EPA’s 2024 Interim Guidance (U.S. EPA, 2024)

In its 2024 Interim Guidance on PFAS Destruction and Disposal, the U.S. EPA highlights two major concerns:

- Landfills can leak PFAS-laden leachate, allowing contaminants to re-enter the environment over time.

- Incineration may produce products of incomplete combustion (PICs)—potentially toxic PFAS byproducts not fully understood or regulated.

These findings cast doubt on the long-term safety of aboveground disposal methods and bolster the case for in situ remediation approaches—like CAC barriers—that avoid PFAS extraction altogether.

Timeframes and Practicality

One of the most sobering findings in the Wurtsmith evaluation was that, despite effective hydraulic containment, the P&T system is unlikely to achieve full aquifer cleanup within a 100-year timeframe. Without supplemental technologies or accelerated removal of PFAS source zones, the system will continue to operate indefinitely—along with the financial and environmental burdens that entails. The CAC approach, while also a containment strategy, offers the advantage of minimal environmental footprint and scalable, targeted applications that do not require continuous oversight. In many cases, this passive containment strategy can become a permanent solution, especially when paired with targeted CAC treatments in source zones that effectively eliminate ongoing PFAS mass flux into the plume.

Regulatory and Institutional Momentum

To date, over 60 sites globally have implemented in situ CAC barriers for PFAS remediation, including numerous DoD locations. The technology is now the subject of multiple ongoing research efforts coordinated by the Strategic Environmental Research and Development Program (SERDP) and the Environmental Security Technology Certification Program (ESTCP).

Conclusion: A Site-Level Decision with Big-Picture Implications

The Wurtsmith AFB case study underscores a broader opportunity facing federal and private site owners alike. While P&T remains an established and accepted approach, its high lifecycle cost, waste generation and energy usage make it increasingly difficult to justify when a more efficient alternative exists. For many PFAS-impacted sites, in situ CAC barriers offer a compelling alternative: substantial cost savings, zero waste, and long-term performance with no system maintenance.

As PFAS cleanup costs climb and Congressional directives call for technologies that eliminate risk in the most "cost-effective and energy-efficient manner", the Wurtsmith AFB comparison compels a reassessment of what truly qualifies as ‘best available technology’ for mitigating PFAS in groundwater

References

Bay West. (2022). Final 2019 Annual Remedial Action Operation Report for Installation Restoration Program Sites FT002, LF030/031, and SS057, Former Wurtsmith Air Force Base, Oscoda, Michigan. January. Oscoda. Administrative Record #613888 https://ar.cce.af.mil

Birnstingl, J. and Wilson, J. (2024), A Cost Comparison of Pump-and-Treat and In Situ Colloidal Activated Carbon for PFAS Plume Management. Remediation Journal, 35: e70005. https://doi.org/10.1002/rem.70005

Carey G.R., McGregor R., Pham A. L. T., Sleep B., Hakimabadi S.G. (2019). Evaluating the longevity of a PFAS in situ colloidal activated carbon remedy. Remediation, 29(2):17-31. https:// doi.org/10.1002/rem.21593

Carey, G. R., S. G. Hakimabadi, M. Singh, et al. 2022. “Longevity of Colloidal Activated Carbon for In Situ PFAS Remediation at AFFF‐ Contaminated Airport Sites.” Remediation Journal 33, no. 1: 3–23. https://onlinelibrary.wiley.com/doi/epdf/10.1002/rem.21741.

DOD (2025). United States Department of Defense. Report on Active, National Guard, and Formerly Used Defense Sites Per- and Polyfluoroalkyl Substances Cleanup Costs. Office of the Assistant for Energy, Installations, and Environment. January 2025. https://www.acq.osd.mil/eie/eer/ecc/pfas/docs/reports/Semi-Annual-RTC-PFAS-Cleanup-Costs.pdf

Hall, L. C., Wilson, J. T., & Birnstingl, J. G. A. (2024). Pandora's PFAS box: Life cycle exposure considerations of treatment options for PFAS in groundwater. Remediation, 34, e21775. https://doi.org/10.1002/rem.21775

MDHHS (2012). Michigan Department of Health and Human Services. https://www.michigan.gov/mdhhs/inside-mdhhs/newsroom/2012/05/02/mdch-issues-do-not-eat-fish-advisory-for-clarks-marsh-in-iosco-county

MDHHS (2019). Michigan Department of Health and Human Services. Memorandum (8-Dec-2019) Public Health Advisory for Wildlife from Clark’s Marsh. https://www.michigan.gov/-/media/Project/Websites/pfasresponse/Folder1/Folder1/Memo-2019-12-08-Public-Health-Advisory-Clarks-Marsh.pdf?rev=59aa5ab597264b02b6b0e53f8e0ac11e

Newell, C.J., Smith, W.B., Kearney, K., Clay, S., Javed, H., Carey, G.R., Richardson, S.D., and Werth, C.J. (2025), Tool and Database for Estimating Potential Longevity of Colloidal Activated Carbon Barriers for PFAS in Groundwater. Remediation Journal, 35: e70017. https://doi.org/10.1002/rem.70017

Strategic Environmental Research and Development Program (SERDP) and Environmental Security and Technology Certification Program (ESTCP) (n.d.). Per- and Polyfluoroalkyl Substances & Aqueous Film-Forming Foam. (n.d.). https://serdp-estcp.mil/focusareas/e18ec5da-d0de-47da-99f9-a07328558149/pfas-afff

U.S. Congress. (2023, October 16). H.R.4365 - 118th Congress (2023-2024): Department of Defense Appropriations Act, 2024. Congress.Gov | Library of Congress. https://www.congress.gov/bill/118th-congress/ house-bill/4365 31.

U.S. Environmental Protection Agency. (2024, April 8). Interim guidance on the destruction and disposal of perfluoroalkyl and polyfluoroalkyl substances and materials containing perfluoroalkyl and polyfluoroalkyl substances—Version 2 (2024): Interim guidance for public comment. https://www.epa.gov/system/files/documents/2024-04/2024-interim-guidance-on-pfas-destruction-and-disposal.pdf

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!