Drillers, Are Your Facilities Holding You Back?

Whether a Manufacturer or a Drilling Contractor, Space has its Limits

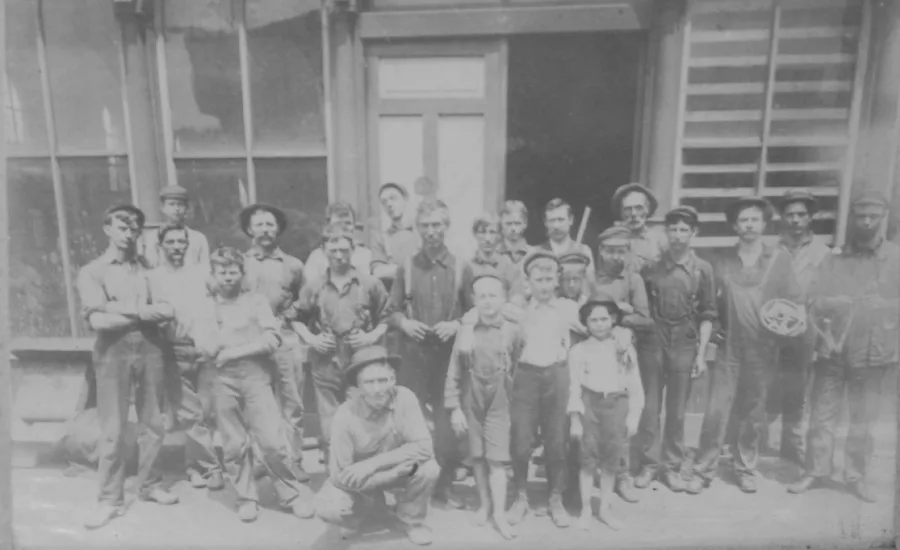

A company columnist David King ran in the mid-1980s bought a building— shown here a much older photo — that had served as a machine shop for decades. He urges companies considering new facilities to ask themselves whether their existing ones hold back growth.

Source: David King

In a recent article in The Driller, I wrote about making the “big” decisions. How do we weigh all the required factors, including the cash investment, against the expected outcome? This details one such decision and how the outcome was surprising.

Investing in adding a rig or, in my case, a new CNC lathe is fairly straightforward. We can calculate what it will add to our businesses as long as we have the work to keep it utilized. But what about when that investment has no direct ties to income? Think about a growing drilling contractor looking to move out of his backyard shop to a larger facility that would house all his rigs and service trucks, and provide more shop and office space.

In the mid-1980s, I ran a manufacturing company in Pennsylvania. We operated out of three buildings and a pipe yard in three locations, but were growing. We had talked about a new building for years.

We owned acreage just outside of town that had a flat area bulldozed. I worked to see how much building we would need to house everyone. The best I could do for this plot was a building that would house everyone and everything but the drill pipe weld line. I rejected this idea because, in addition to not housing everything, it left no room for expansion. After all, we could move a lot of stock between our locations for the price of a new building, right?

An opportunity arose to acquire a former shoe factory seven miles away with 64,000 square feet on 24 acres. I knew the building. I had worked the night shift in that shoe factory the summer after my senior year of high school. It did have some issues, largest drawback being the low ceiling in the largest section. We needed overhead traveling hoists. I called in a crane/hoist company of Pittsburgh and they came up with a design that gave me a workable clearance. Aside from the largest section, it had two 40-by-500-foot bays and, if I recall correctly, two 45-by-160-foot sections with really high ceilings. I salivated thinking about the workflow. The game was afoot.

So, I went to the board for approval. We would need to attend an auction in a courthouse near Wall Street in New York City. I had an estimated cost to renovate and install our overhead crane system, and wanted to take enough money to cover it if the bidding went up to $350,000. I figured that if it went higher, we should wait and build. In presenting to the board, though, it became a matter of how to estimate the gains we could experience being under one roof.

Despite my pleas and best estimate of the numbers, the board decided the most I could spend was $125,000. I convinced our accountant to give me checks to cover an additional $20,000, just in case. Checks in hand, I flew to New York.

The next day, I went to the courthouse. When our turn came, I found myself bidding against a guy from a neighboring town. Bidding went from $60,000 to $120,000 fast. When the bid $125,000, I worried things were not in my favor. But, when I threw out my best and final offer — $145,000 — my opponent dropped out.

I reported to the board that I spent $145,000 on a building for which they had authorized $125,000. I took full responsibility (whatever that means), not for the buying the building but failing to convince them of the value. We would have everything we wanted (after renovations) for less than half of a new building that did not house us all.

We moved in our equipment after renovations, laying out the floor to match the scale model we made. Our foremen led a smooth transition as we combined our various locations into one. For the most part, it worked well. Sales and management offices sat on a second floor with production offices below.

What about the outcome? Did it meet expectations? It still took 2¼ hours to make a sub on a manual lathe and mill. It still took the same amount of time to run a drill rod through the line. Yet, during our first year, our production increased by at least 30%! I had hoped for maybe 10%. So what happened? Where did this extra performance originate?

Yes, we eliminated the time and effort moving materials by truck between our three buildings. Before we built drill pipe in the pipe shop and subs in the main building. Now we could use pipe shop equipment to build stabilizers or hoist plugs. We had space to place CNC equipment in pods so operators could run more than one machine. We had improved equipment and personnel utilization. We expected all of this, to a certain degree.

But I think the biggest gains came from management. Every morning we could have a production meeting with all floor supervisors, our material handler and myself. We would review the in-house orders and look at the priorities. All our floor supervisors could get the entire picture. Salesmen could sit in and learn the status of orders, instead of running to me or the floor supervisors. I could walk the floor. None of this was feasible before we were all under one roof.

Looking back, I had grossly underestimated the gains we experienced. Our production shot up, as did our profit margins. If the building bidding had gone higher, we would have lost that opportunity. It would have cost us millions of dollars gains. Most people look to make sure that the investment will at least pay for itself — a do-no-harm philosophy. But, in concentrating on not losing money, do we pass up opportunities because we low-balled the gains? What could more space do for you? Just something else to think about.For more Pipeline columns, visit www.thedriller.com/pipeline

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!