How Do I Pick the Best Coolant for My Diesel Engine?

Tips for Getting Optimal Heat Transfer in Diesel-Powered Equipment

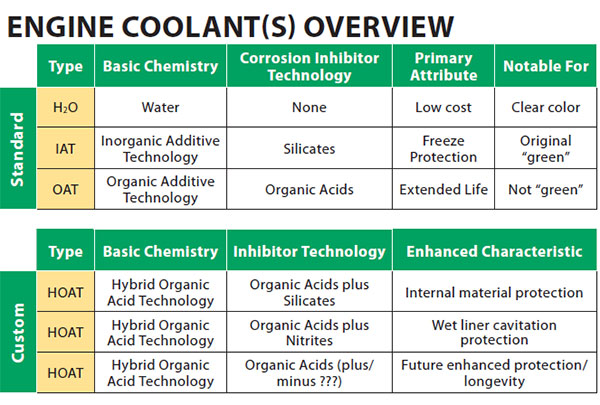

The familiar green coolant we’re all used to is now complemented by products that come in a rainbow of colors. But educate yourself: Color isn’t the best criteria for selecting the best coolant for any given engine.

In the world of those tasked with punching holes in the ground, cooler heads must prevail to accomplish the required work each day.

Of course, drill crews need cool heads and even tempers. But I speak here about the diesel engines used in many of the machines onsite, and of such things as cylinder heads and combustion chambers. They are sources of considerable energy and, thereby, heat and require focused attention to transfer heat and bring it to the radiator to be dispensed with. This column will offer insights into our engines’ cooling systems, and give operators tips for getting the most out the heat transfer that happens within.

Jump to...

Vigorous Air

When one stops to consider the tremendous amount of heat generated from continuous diesel combustion, it’s a wonder that simple air could be used to cool things off at all. But, indeed, it has worked effectively for many years and on some rather large engines. These days, however, most engines of significant size use liquid coolant. Emissions regulations demand closer engine tolerances not workable for many air-cooled engines.

Should you have an air-cooled engine on your site, the key is to keep it as clean and free of debris as possible. Don’t let things gradually worsen because no one pays attention. What could have been nipped in the bud through a little attention can turn into an engine failure due to a plugged air system.

Courageous Water

When it came time to lean on something more substantial for transferring heat, water generously stepped to the forefront. We know how effective it is as a heat-transfer medium. Pure, clean water is one of the best of the bunch in terms of its capability to do work — heat transfer capability, specifically.

In fact, in a substantial segment of the world, water is used as a base coolant and continues to work just fine. Major engine companies sell simple chemical packages that, when added to water, offer further protection for the engine internally. But water does the heat transfer work.

Miraculous Antifreeze

In freezing temperatures, things change. We cannot have water in an engine block that would expand and quickly damage it. What was initially referred to as “antifreeze” was developed from a helpful base fluid of ethylene glycol (EG). The initial mixture would be EG with corrosion inhibitors added — silicates in particular — and topped off with the requisite amount of water to achieve the necessary freezing value. Those corrosion inhibitors are called inorganic additive technology (IAT) products. The “inorganic” terminology will be clearer shortly.

This product is, of course, the familiar “green” coolant. Good stuff. And still perfectly fine for many engine applications, including current small diesels as well as many legacy products still in service. It has been a wonderful ally for many years, and we can expect that it has many more years of life left.

As a side note, “antifreeze” is a bit of a misnomer. In addition to “not freezing,” the product also offers the benefit of a higher boiling point.

Stupendous OATs

Which brings us to where we are today. The range of products now available complicates things, but also provides considerable performance and operational benefits. Operators just need to be savvy enough to understand those products and treat them properly.

What we know from basic chemistry is that the base glycol product itself (ethylene mostly, but propylene for some formulations) has a long-life in engine usage — basically forever. The problem is with the corrosion inhibitors. So what’s been developed in recent years are organic additive technology (OAT) products, which offer a considerably longer coolant life in engines when compared to IAT products.

With the advent of OAT products, which is good overall, it seems that the coolant folks now have a slew of available products in all the colors of the rainbow. But what promises regarding a particular color and universality in usage — and whatever other such promises — might leave the unwary disappointed at the end of such a rainbow? Our first warning: It’s not a good idea to pay too much attention to color as a confirmation of usage. That said, providers of these products — independents, as well as engine companies — have worked diligently to develop a range of modern-day recipes for every operational need. That includes accommodating the characteristics of water in particular regions.

As an example, the hard water commonly found in Europe has led to products specifically for use in engines operated in those countries. Likewise, Asian suppliers, in the interest of better heat transfer, prefer phosphates to silicates as corrosion inhibitors. Many regions benefit from specific mixtures for these products.

The important thing to understand and remember is that product availability has expanded considerably. It is critical to determine the needs for a particular engine. Select a product and stick with it to the end.

Diesel Dictates

For diesel engines with wet liners, it’s crucial to protect against cavitation damage. This type of erosion occurs when a hot “air” spot collapses, resulting in a shock wave so severe that it can pit the metal. The engine companies seem to each have their own approach (i.e., blends) for minimizing this, but we can be sure that each company has tested and proven their product, and use of it will protect the engine.

Again, select a product and stick with it to the end.

Some Important Things to Remember

Let me summarize and offer some parting thoughts on engines and the coolants that keep them operating as designed.

- We know how clean water can be these days. If you’re not 100% certain that you can get very good water for mixing, buy the blended stuff.

- Water pumps are essentially designed to smoothly move the coolant around, not blend it. It’s critical that the coolant is fully mixed before it’s added to the engine cooling system. Otherwise, a pocket of the heavy glycol can remain in place and restrict effective heat transfer.

- Relying on color to know what coolant is needed or is being used for a particular engine is just not a good idea overall.

- Coolant test strips are now available to check the overall condition of the coolant in place. A check as to how it looks can also be helpful.

And remember: When cooler heads do, indeed, prevail, there’s no limit to how much work can be accomplished at the drill site each day. Just a reminder.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!