Contractor Tips: Polymer Selection for Drilling Fluids

Finding the Right Fluids Recipe for your Ground Conditions

Source: CETCO Drilling Products

Source: CETCO Drilling Products

Polymers and additives enable drilling contractors to match drilling fluids to soil conditions to maximize performance, efficiency and success. Polymers were first used with drilling fluids in the 1930s when drillers added cornstarch was added to fluids to enhance filtration control and provide better borehole stability in coarse soil conditions.

Drilling fluids technology has advanced tremendously since the 1930s and the number and variety of polymers and additives available to drilling contractors can be overwhelming. With this article, I aim to help drilling contractors in selecting polymers to match drilling fluids to soil conditions to maximize drilling efficiency.

The three key soil control functions of a drilling fluid that contractors should focus on when matching drilling fluids to soil conditions are:

- Keeping the hole open

- Suspending and transporting drill cuttings

- Controlling reactive clays

Water, bentonite and water, and/or a polymer fluid will not perform all of these functions for rotary mud drilling. By starting with a bentonite based drilling fluid and selecting the correct type of polymer, or combination of polymers, one can tweak or adjust drilling fluid to various soil conditions encountered to complete the drilling project in the most cost-effective way. Ironically, there are three categories of polymers used in drilling fluids:

- Synthetic

- Natural/biodegradable

- Modified natural polymers

These three categories directly link with the three previously mentioned functions of a drilling fluid.

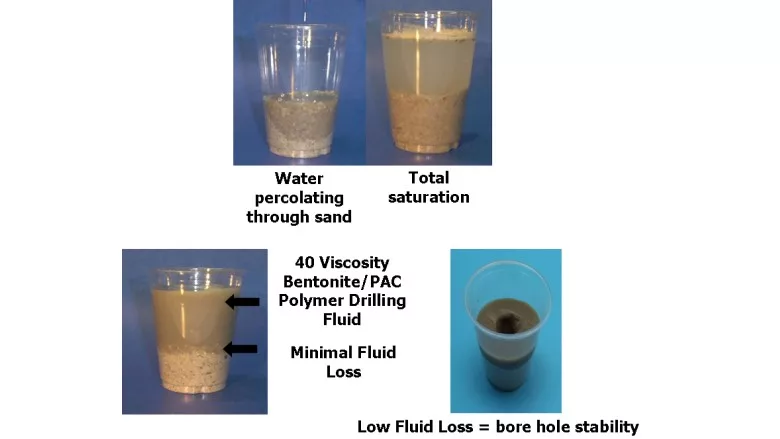

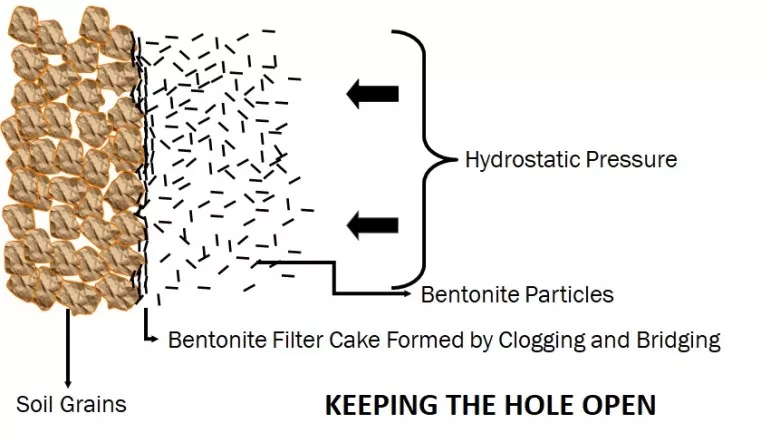

For a drilling fluid to maintain borehole stability/keep the hole open, the drilling fluid must form an almost impermeable barrier between the soil and the drilling fluid that positive pressure can be applied against to stop the hole from collapsing in coarse soil conditions. Bentonite drilling fluids accomplish this with microscopic platelets that shingle off on the walls of the borehole to form a filter cake that stops fluid from permeating into the formation (filtration control). Hydrostatic head pressure, from having the borehole full of fluid, applies the even positive pressure against the filter cake to stabilize the formation and keep the hole open. There are two ways to increase filtration control to maintain borehole stability. One is to add more bentonite, which raises the viscosity/thickness (resistance to flow) of a drilling fluid. However, this can lead to other problems that reduce drilling efficiency. A great alternative is to add a polyanionic cellulose (PAC) polymer, which is a modified natural polymer made from cellulose (plant fiber), that greatly enhances filtration control with a minimal increase in viscosity. PAC polymers are also available in low-viscosity formulations that make them even more efficient.

Gel strength is a description of a drilling fluid’s ability to suspend drill cuttings, especially when the fluid is at rest (mud circulation has stopped). The previously mentioned microscopic bentonite platelets have a negative electrostatic charge and the platelets repel each other to form gels that suspend drill cuttings. Xanthan gum is one of the most frequently used biodegradable polymers and can dramatically increase the gel strength of a drilling fluid, enabling the drilling fluid to suspend larger and heavier drill cuttings with a minimal increase in viscosity. Some biodegradable polymers such a guar gum can be used as a standalone biodegradable drilling fluid, but have a very short useful life before going bad.

Adjusting the pH to between 8.5 and 9.5 with soda ash neutralizes calcium and greatly enhances the performance of all components of a drilling fluid.

Reactive clays can cause numerous problems for rotary mud drilling including balling up around the bit, restricting annular flow, excessive torque and more. Clay must absorb water to swell and get sticky, and synthetic polymer can inhibit the swelling of reactive clays by coating clay with a polymer film that delays the hydration. Long-chain/high-molecular-weight synthetic polymers are most commonly used to control reactive clays. However, operators using drilling fluids recycling systems, should know these synthetic polymers can cause screen blinding, which results in vibratory screening equipment discharging large amounts of fluid on the ground. Low-viscosity/short-chain synthetic polymers are available to help control reactive clays without blinding vibratory screening equipment and result in a minimal increase in viscosity of a drilling fluids system. PAC (polyanionic cellulose) can also be used to control reactive clays and will not bind the screens on drilling fluids recycling equipment.

Bentonite must be fully yielded before adding any type of polymer to a bentonite drilling fluid. One can simply dip their hand in the drilling fluid and check. If there are still lumps of un-yielded drilling fluid, additional mixing time is needed before adding the polymer. Otherwise, polymer can coat the unyielded lumps of bentonite and prevent the bentonite from fully yielding. Like bentonite, polymers and even drilling detergents, are negatively affected by calcium in mix water. Adjusting the pH to between 8.5 and 9.5 with soda ash neutralizes calcium and greatly enhances the performance of all components of a drilling fluid.

As previously mentioned, polymers and additives enable drilling contractors to match drilling fluids to soil conditions to maximize performance, efficiency and success. Understanding the three key soil control functions of a drilling fluid and the three types of polymers used with drilling fluids can help drilling contractors in selecting the correct polymers to use.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!