Tips for Working Safely Near Overhead Power Lines

Plus, What to Do if Your Drilling Rig Mast Arcs to a Hot Line

It’s not uncommon for contractors to have to mobilize near power lines. When you do, following OSHA’s guidelines for safe approach can help minimize risks for workers.

Source: Getty Images

I recently conducted a survey of about 30 workers with less than four years of experience in our industry. I asked them two very simple questions:

- Do you feel safe in your job?

- What act or situation made you feel the most unsafe?

I can't take credit for the first question. Industry trainer and fellow The Driller writer Brock Yordy likes to ask all of the workers he meets that same question. He recommends employers ask often during an employee’s first year of employment, then periodically after. For this exercise, I thought it would be interesting to ask the same question from the outside — not working for the companies that employ these young drilling professionals — and follow up with the second, clarifying question. I almost always got the same answer to that second one: working too closely to overhead power lines.

To be honest, I was a little taken aback. Approach distances for overhead power lines are common knowledge, aren’t they? At the Apprentice and Skill Improvement Program, we train apprentices on Occupational Safety and Health Administration (OSHA) regulations for overhead power line approach distances. If these apprentices out in the field have concerns that tells me their drillers are either untrained or unconcerned. Crews that fail to maintain safe approach distances greatly increase the possibility of a catastrophic event. Each time “nothing” happens when we work closer than we should to overhead power makes us more likely to make a similar mistake in the future. Each one of these unsafe acts get us closer to that catastrophic event happening. This is called Heinrich’s triangle.

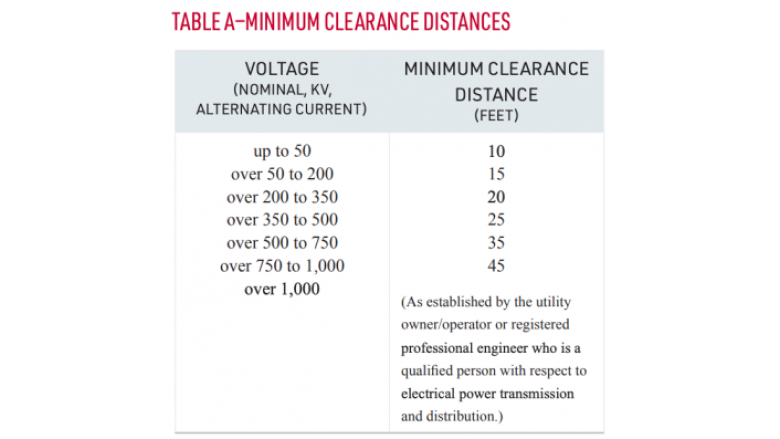

OSHA’s General Industry Standard 1910 requires that all equipment must maintain a minimum 10-foot clearance from energized power lines of 50 kilovolts (kV) or less. That includes service entrance cables (unless insulated). As the voltage (and therefore the danger) increases, the distance increases by .4 inches for every kV over 50 kV. This awkward number comes from the original standard, was in the metric system, and 1 centimeter equals 0.4 inches. In OSHA’s 1926 Construction Standard, the agency gives minimum clearance distances for different voltages in a table. Those distances equate to the .4 inches for every kilovolt over 50 kV. If voltage for a line is unknown, a good guideline for minimum safe clearance is twice the length of the line insulator, but never less than 10 feet.

Source: International Union of Operating Engineers

Yeah, Powers Lines are that Dangerous for Workers

Many workers may not clearly understand the gravity of working too close to a power line. Of course, most everyone understands that contacting a power line could kill. What many people don’t know is that being just a little closer than OSHA allows can have the same fatal results. It’s risky and careless, but workers who may “get away” with it once often continue to push the limit.

If you’re on a jobsite and consider pushing that limit or see someone else doing it, I recommend a pause to consider a few facts about power line contact:

- Overhead lines are typically not insulated. The covering workers see generally protects the line from weather, not a worker from electrocution.

- Over 90% of reported contacts occur on overhead distribution lines, which is a real concern to drillers.

- Drillers are normally safe if they stay on the equipment’s platform, keeping them from being a path to ground (like a bird on a wire).

- Ground personnel (like drilling assistants) are over eight times more likely to die during a contact incident. When the equipment connects, the current in the overhead line takes the quickest path to ground and will flow through them.

- It only takes 2 amps directly across your heart to stop it from beating.

Remember, contact is not the only way an overhead power line can energize a piece of drilling equipment. Drilling contractors typically work in all types of weather. Rain, mist, fog or even dust can all serve as conductors between an energized power line and the mast of a drill rig or pump hoist. In these cases, even OSHA’s minimum safe approach distances may not provide ample protection. Safe approach distances make the possibility of an arc from an overhead power line to another conductor unlikely, but not impossible. Once you introduce these “atmospheric” conductors between the line and the mast, the possibility of an arc increases.

Remember, contact is not the only way an overhead power line can energize a piece of drilling equipment. Drilling contractors typically work in all types of weather. Rain, mist, fog or even dust can all serve as conductors.

I remember early in my career having to work close to a power line. The contractor I worked for had the line “booted.” They placed a bright-colored cover over the line, which at the time I thought meant that I could work closer than the 10 feet outlined by OSHA. However, since becoming an OSHA outreach trainer I’ve learned booting only increases visibility. According to the power company, it does not give you license to decrease your approach distance.

The only safe way to decrease your minimum approach distance is to have the line de-energized. However, do not let the power company just tell you they de-energized the line. The National Ground Water Association put out a safety video years ago where a company safety officer relays a story about asking the local power company to de-energized a line they needed to work within 2 feet of. The utility came back later and told the company it had de-energized the wrong line. The company had been working within 2 feet of a live line for a week. To avoid this type of situation, the line should be de-energized and grounded with visual verification on the jobsite.

What to Do If Your Rig Arcs to a Power Line

So what do you do if you actually make contact or your rig arcs to a power line?

If you are on board a drill rig or hoist truck energized due to contact with an overhead power line:

- First, try to move the mast or boom at least 10 feet away from the lines.

- If the equipment can’t be moved, but you must get off because it is on fire, never touch the equipment and the ground at the same time.

- Jump clear of the rig and land upright with your feet close together. Be sure not to fall backward and contact the rig.

- Warn others to stay away.

- Have everyone “shuffle” out of the area, keeping their feet in contact with each other and not letting their heel run past the toe of their opposite foot. This must be done because different areas of “potential” could develop around the drill rig or hoist. If you step across areas of two different potentials, current will flow through you to reach the other area. This can potentially cause electrocution or severe burns.

- Call the utility company and wait for them to de-energize the lines.

If you are not on board, stay away from rig or hoist truck. Never touch any connected winch cables, drill steels, pipes or hoses. Never attempt to assist an injured worker until the equipment is de-energized. Current could still be flowing through the victim.

If power lines appear to de-energize automatically, stay away; the lines could automatically re-energize. Lines can often re-energize three or four times automatically. This reduces service calls for the utilities in cases where the short was due to a tree branch or animal.

Until next time, stay upbeat and energetic — but avoid being energized — and keep turning to the right.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!