On Drilling Jobs, Tracking Near Misses is Critical

Drillers are professionals and know how to get the job done, but they are also human. Everyone who operates heavy equipment has had “that could have been bad” moments on the jobsite.

Source: Dave Bowers

A month or so prior to the writing of this article, I was sitting in a hotel room in Pittsburgh, Pa., when I received a text message from my wife. The text contained a screenshot of the Facebook page of a driller that I know, simply stating: “Thank God I’m alive today. God was watching over me and my coworkers.” I phoned the driller who had posted it to find out what happened.

The story was simple. Two geotechnical drill crews were working on the same site in an urban area doing soil borings along a roadway. There was a driller with 10 years of experience on one rig and a newly promoted driller (the one who posted to Facebook) on the second rig, both accompanied by relatively inexperienced helpers. The more experienced driller set up and began to try to “set the pace” — drilling a boring, then moving, drilling and moving. The less experienced driller took a little more time per boring, but was attempting to keep up with the other crew. After about six hours, it happened. The more experienced driller moved to a new hole, leveled his rig and began to raise the mast, causing contact with overhead powerlines!

I know what you’re thinking … that is an incident, not a near miss as the headline states. The story continues. The driller panicked. Instead of trying to lower the mast to try and break contact with the line, he jumped off the rig and ran away. (Near Miss 1.) This prompted his helper to also run away from the rig. (Near Miss 2.) The two drill crews discussed what to do, as now the jacks of the rig in contact with the powerline were beginning to smoke. It was then that the less experienced driller decided to approach the smoking rig and push the tower lever to lower the mast. He used a wooden shovel handle to push the lever, since he figured that wood was nonconductive and he had rubber boots on. (Near Miss 3.)

This revelation over the phone led to about 15 minutes of me telling him, in words that cannot be printed here, that it was one of the worst things he could have chosen to do. His family would be without a father if it were not for dumb luck. I informed him that energy fields can be set up around the grounded object. If a person steps across two different levels of potential or touches an object at a different level, electricity may pass through you and you could be electrocuted.

This got me thinking about all the “that could have been bad” moments in all our drilling careers. In 2018, there were a number of major injuries and fatalities in the drilling industry nationwide. How many of the people who are now statistics had made an unsafe action or choice in the past, and nothing bad happened or “no one got hurt”? Did they report it to the company?

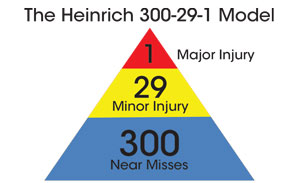

Who hasn’t pulled the wrong lever, or reached across the rotary drive to grab something, or dropped a rod, or told that new guy not to put their hand there, or a million other things that could have gotten someone hurt? Every time no one got hurt, but someone could have, it puts us closer to the time somebody does get hurt. This ratio is known in safety circles as the Heinrich model (or Safety Triangle), which states:

-

For every 300 near misses (those “that could have been bad” moments), we can expect 29 minor injuries (for which medical treatment or first aid is provided, but which do not result in a lost or restricted workday),

For every 300 near misses (those “that could have been bad” moments), we can expect 29 minor injuries (for which medical treatment or first aid is provided, but which do not result in a lost or restricted workday), - And one major injury (resulting in lost time or a restricted workday).

Tracking near misses gives us the opportunity to respond to safety concerns before some type of injury has happened. It may lead us to change the way we do something from “we have always done it this way” to a safer alternative. We may identify hazardous attitudes in ourselves or our drill crews. The contractors in the example had done everything in their power to give their crews the knowledge and training needed to make them safe and efficient. Everyone on site had OSHA 10-Hour Hazard Awareness Training and had attended toolbox talks on overhead hazards. They all knew the right things to do, but in the heat of the moment, they made poor choices.

No amount of production can make up for an injury or fatality. Capital equipment is replaceable. All drill crews must try to establish situational awareness of the environment and the rig condition before beginning work on a new site or new location, or beginning a new shift. All near misses should be reported and tracked to identify problems prior to an accident. Drill crews should look for attitudes that could be a barrier to safety. These might include:

- Impulsivity: “Do it faster!”

- Anti-authority: “Don’t tell me!”

- Or invulnerability: “It won’t happen to me!”

All of us have, from time to time, exhibited these traits. Oftentimes, they are a precursor to doing an unsafe act.

Related Articles

Drilling is full of hazards. We all accept some risk every time we turn the bit. Keeping records of near misses may sound like a hassle, but the changes it could lead to in improving the culture of our industry could be huge. An injury, or worse, for your company or family could be catastrophic. The savings in heartache, as well as finances, from a little prevention cannot be overstated.

When it comes to safety, we all must be our own hero. Look around. You’re probably already someone else’s superhero.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!