HDD Drilling — Drilling with Water Only?

Maximize Feet per Day with the Right Fluids Mix

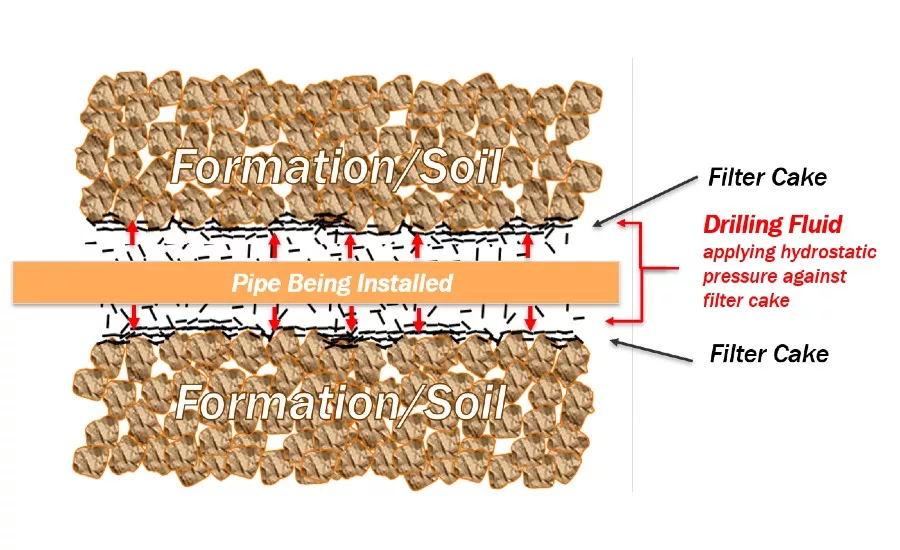

A properly-built drilling fluid, left, forms a barrier with soil it contacts. Water alone, right, seeps into and hydrates the formation. That can result in inadvertent returns, or stuck, broken or stretched pipe.

Source: CETCO Drilling Products images

Over the last 5 years, there has been a substantial investment in the installation of fiber optic networks throughout North America. The demand for data and fast internet service have increased even more this year due to the impact of Covid-19, as more people work from home and students learn virtually. Major telecommunication operators plan to further expand their networks in 2021.

Horizontal directional drilling (HDD) is a trenchless method to install fiber optic networks that has little impact on the surface and, therefore, is a preferred method in populated areas. Small HDD rigs, which have a small footprint, are utilized and can mobilize into areas with limited access.

It is common for HDD drillers to be paid by the foot for installation, so an operator’s profitability depends on the amount of drilling completed each day. Some HDD companies attempt to save expenses by drilling with only water. (This can also reduce any cleanup required before the rig mobilizes to the next site.) However, we have found over the years that drilling with water only results in many issues, including stuck pipe, excessive wear on equipment and extra downtime. All of this results in less footage drilled per day. The most successful drillers, small and large, understand the need for the proper use of drilling fluids.

In this article, I will outline a few of the top reasons to drill with the proper drilling fluids, and why pumping water only can slow a drilling operation down.

Lubrication

Pumping water only provides no lubrication downhole, increasing the wear on tooling and rods. Drilling in coarse, unconsolidated ground like sand and gravel with water only multiplies that wear. Increased wear on tooling slows rates of penetration and raises costs, since the tooling replacement becomes more regular. Pumping a drilling fluid provides lubrication that reduces wear, increases rates of penetration, and results in longer life for drill bits and rods.

Create a Hole/Transport Cuttings

To create a hole to pull pipe through an HDD bore, the cuttings need to be transported out of the hole to make room for the conduit. Water along cannot hold up cuttings and transport them out of the hole. If you take a cup of water and add sand, the sand falls right to the bottom. The same thing takes place downhole. A drilling fluid is non-Newtonian fluid, therefore it has gel strength to hold up sediment and carry cuttings out of the hole as it pumps through the bit or reamer.

Stabilize the Hole and Control Fluid Loss

As the cuttings move out of the hole, operators have to keep that hole open. We call this stabilizing the hole. Pumping water only cannot stabilize the hole. If drilling in sand, the water flows into the formation and the hole collapses behind the tooling. Trying to pull the pipe through a collapsed hole can easily result in inadvertent returns and the pipe getting stuck, broken or stretched as the rig attempts to pull the conduit through the weight of sediment piling on top.

Pumping a drilling fluid, on the other hand, stabilizes the hole by creating a filter cake along the borehole wall that traps the drilling fluid in the hole. The positive hydrostatic pressure exerted on this filter cake stabilizes the hole while the cuttings are being transported out. The lubricity of the drilling fluid also allows the conduit to pull through the stabilized hole with little pull force exerted by the drill.

Reduce Torque Associated with Sticky Soils

Clay and shale are also known as reactive soils. They can swell and/or become sticky in contact with water. This can cause many issues if pumping with water only when drilling. Water pumped downhole will wet the surface of the clay. Once the water hydrates the clay, it causes sticking and swelling. The clay balls on the drill bit and increases the rotational torque of the drill. A hydrated clay downhole may also stick to pulled conduit, which increases the pull force exerted by the drill. This often results in stuck, broken or stretched pipe.

Trying to reduce costs by pumping water only while drilling will result in excessive equipment wear, slower rates of penetration, stuck conduit and increased downtime. Over the course of a long-term contract, this has a large impact on a contractor’s profitability.

The use of a proper drilling fluid reduces the effects of swelling and sticking clay. The drilling fluid can encapsulate the clay to slow and reduce its hydration. Some drilling fluids are also designed to break down clay and allow it to be easily flushed from the hole. This reduces the rotational torque of the drill and allows for conduit to pull through the hole with little pull force.

Drilling companies installing fiber optic conduits through horizontal directional drilling want to drill as much footage as they can each day. This maximizes profitability over the long term. Trying to reduce costs by pumping water only while drilling will result in excessive equipment wear, slower rates of penetration, stuck conduit and increased downtime. Over the course of a long-term contract, this has a large impact on a contractor’s profitability. The use of drilling fluids will alleviate many issues discussed in this article, with the most tangible benefits seen in higher output and increased profitability in the long run. For these small-diameter, short bores contractors have many choices in drilling fluids including bentonite- or polymer-based options. Contact your drilling fluid provider for the proper fluids to improve your productivity today.

For more Drilling Fluids columns, visit www.thedriller.com/drillingfluids

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!