Using Mixed-Metal Oxide with Small to Medium HDD Rigs

MMO Behaves Differently, but Effective in Unconsolidated Formations

Rocks sit atop MMI drilling fluid. The gel structure forms almost instantly without shear applied, preventing any settling of sand, cobble or rock.

Source: CETCO Drilling Products

Most HDD contractors operating small- to medium-sized rigs have standard mud mixtures they use when drilling in different ground formations. When drilling in unconsolidated sand, gravel or cobble, operators typically react by thickening the drilling fluid, as this reduces filtrate loss and helps carry the cuttings out of the hole. Several issues may arise from this practice:

- Small rigs may not be able to pump enough high-viscosity fluid to keep up with the drilling speed.

- Pump pressures will rise considerably in longer bores.

- Hydraulic fracture may result from excessive drilling fluid pressure.

- Unconsolidated gravel or cobble could collapse during drilling resulting in stuck drill stem/pipe.

In these formations, operators may want to consider mixed-metal oxide (MMO), especially if they run small to medium rigs. People often hesitate to use MMO, as it behaves much differently than a typical mixture of bentonite, PAC and xanthan gum. For example, you cannot perform some typical tests — like viscosity testing with a marsh funnel —when using MMO.

Many will ask, “What exactly is MMO and how does it work?” Greg Plutko, research and development scientist at CETCO Drilling Products, shares his insight into mixed-metal oxide:

- At pH 10 to 10.5, the MMO is a weakly cationic particle. It is roughly 1/10th the size of a bentonite platelet and has a hexagonal, plate-like shape.

- Each MMO particle can bridge two or more bentonite particles, thus increasing those important inter-particle interactions that suspend cuttings.

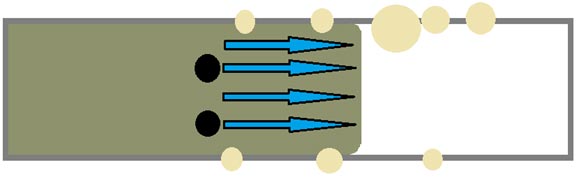

- This boosts the yield-point value, decreases the plastic-viscosity value and leads to a more shear-thinning fluid.

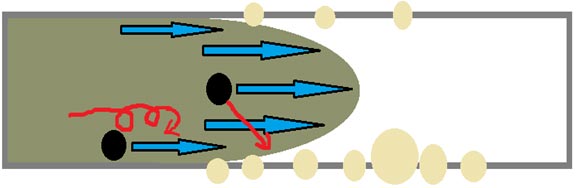

- MMO muds are so shear thinning, in fact, that they quickly convert to a water-like rheology as soon as any significant shear is applied. The MMO particles pull away from the clay surface easily.

- At rest, it converts back into a strongly interacting network of platelets.

- Unlike most fluids, this gel structure forms almost instantly, thus preventing any settling of sand, gravel and rocks.

- MMO fluid flows out into the formation from the borehole wall a short distance and then gels, effectively filling and sealing voids and cracks. This prevents further fluid loss.

This unique rheology results in a plug flow that further aids in the removal of suspended solids from the borehole.

Operators I work with find utilizing MMO for small to medium HDD rigs very effective when drilling through coarse sands, gravel and cobble. It reduces issues typically seen with high-solids drilling fluids. First, no other fluid can suspend large cuttings as effectively. It will move golf ball-sized rocks out of the borehole. It works well at lower pumping rates, so even small rigs can produce enough flow to keep up with drilling speeds. Downhole pressure remains low, reducing the risk of hydraulic fracture. The fluid fills voids and cracks along the borehole wall, and then stops quickly as it gels firmly, which results in strong borehole support. Finally, an MMO fluid works extremely well with recycling systems. It will not blind scalper screens. In fact, it flows through the screens like water.

To mix a MMO fluid in the field, first treat the water with soda ash to reach a pH of 10+. Then, add bentonite and mix until fully hydrated. The contractor can utilize multiple bentonite gels. Preferably, use an untreated bentonite gel; however, high-yield gels can also be used. Once the bentonite fully hydrates, add the MMO and mix it until the drilling fluid has a pudding-like consistency. The drilling fluid at rest will appear so thick that it will not have a smooth surface.

Drilling in gravel and cobble with a small to medium HDD rig can seem like a difficult task. It doesn’t need to be. Utilizing the right tools can make a job easier and more successful. I highly encourage contractors to consider the use of a MMO fluid in these types of ground conditions.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!