A Driller’s Primer on Wire Rope Connections, Rigging

Often When It Fails, it’s the Connection not the Rope Itself

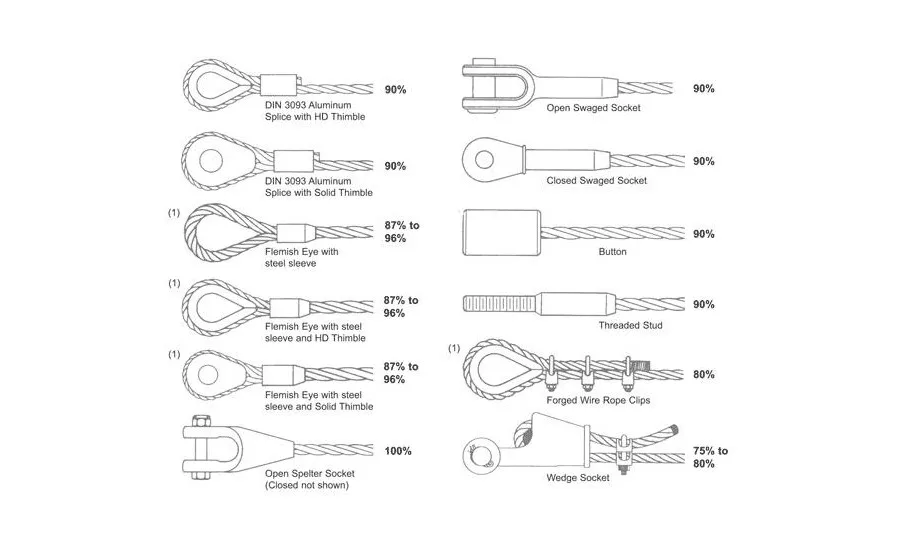

Different connections each have an effect on the overall breaking strength for wire rope.

Source: Dave Bowers

The past few months, my articles have centered around wire rope safety and inspection, and this month is no different. However, this is the last of the wire rope articles. The topic this month is end connections and rigging. End connections and rigging? It’s a fancy way of talking about what attaches the hook to the wire rope, as well as everything that hangs below the hook. Although wire rope failures can happen, much of the time when I have witnessed a deficiency or incorrect usage, it is at or below the hook. This is particularly alarming because drilling crews are next to or handling the hook often, increasing the likelihood of injury in event of a failure.

End Connections

An end connection attaches a hook or other load-bearing item to the end of a wire rope. These come in many forms, from buttons and sockets swaged on by the manufacturer of the wire rope, to wire rope clips and wedge sockets installed in the field. All types of connection are widely used in drilling. However, all but an open spelter socket come with a 5 to 25% reduction of the breaking strength of the wire rope.

Let’s look at the four most common types of end connection used on drilling rigs.

Spelter sockets are the only widely available end connection that preserves 100% of a wire rope’s strength. They are easy to attach a hook or other load-bearing item too if the correct type of socket is ordered. To attach, the wire rope is first trimmed to length. The socket slips over the individual strands and core of the wire rope, which are then trimmed and unwound. A “wire lock” wedge is installed, and the socket slipped over the wedge and wires. Resin is pored into the cavity, locking the socket in place. Spelter sockets must then be tested to their working load by the rigging and wire rope supplier. This is all very labor intensive and makes spelter sockets an expensive option. Most rig manufacturers only use them out of necessity.

Swaged sockets are the most common type of preinstalled end connection. These are hydraulically pressed around the wire rope and provide a 90% capacity. Swaged sockets are much cheaper than spelter sockets.

The problem with both these types of end connections is they are a one-time use. If a rope is damaged even very near the hook it cannot be shortened. But what happens when a wire rope is cut short?

Most drillers have some experience with wire rope clips. One of the first things I learned as a helper was the saying “never saddle a dead horse.” But I even occasionally new rigs at trade shows with wire rope clips on a hoist line. When the right type and proper number of clips is installed properly on a rope, they provide an 80% capacity. The key words in that sentence are “correct type” and “installed properly.”

The wedge socket is the last and, for my money, best end connection for hoist lines that can be installed in the field. Wedge sockets are easy to install and remove, and have the same 80% capacity as wire rope clips.

There are two types of wire rope clips: drop-forged and malleable. Drop-forged clips are for sustaining overhead loads. Malleable clips are lightweight and not to be used for anything overhead. Clips purchased at a farm or hardware store, and not a rigging supplier, are more than likely malleable ones and should not be used in drilling operations. If your clips are forged, they can be used for standing ropes or guy lines but are not recommended for overhead lifting.

Drillers using clips need to refer to manufacturer recommendations for spacing and torque specs. Also, make sure that the U bolt is on the short or “dead end” and the saddle on load side or “live end.”

The wedge socket is the last and, for my money, best end connection for hoist lines that can be installed in the field. Wedge sockets are easy to install and remove, and have the same 80% capacity as wire rope clips. They can be used for overhead lifting. I personally feel like the Terminator wedge socket made by The Crosby Group is the easiest to use. It is available for any size of wire rope commonly used for hoisting. Just like all end connections, wedge sockets must be properly installed with the live end of the rope in line with the pin. Also, the dead end of the wire rope must extend at least 6 inches out of the top of the socket or six rope diameters, whichever is greater, for standard wire rope or 20 diameters for rotation-resistant wire rope.

Hooks and Rigging

Hooks used for hoisting operations must be marked with the rated capacity of the hook, must be fitted with a swivel and must have a safety latching system. Hooks must be inspected for twist and throat opening wear, and must be replaced if twist of over 10 degrees or throat opening wear greater than 15% are found.

Screw pin shackles, also called farm clevises, must be marked with safe working load and inspected for wear and straightness. Shackles must also be used in a manner that will not make the pin back out, which is the most common improper use. Somewhere along the line, it became a misconception that operators should hand tighten the pin and then back off quarter a turn. This is incorrect. The screw pin must be tightened by hand until the shoulder of the pin is in contact with the body of the shackle. Otherwise, the safe working load cannot be realized. When two or more chokers are used, put choker eyes in a shackle with shackle pin on the hook to prevent the pin from loosening.

Wire rope slings must be inspected before each use to detect possible damage. Ensure all parts of the sling are readily visible before performing a visual inspection of the entire sling. If necessary, remove dirt and grime so wires and components are visible. Look for any of the conditions listed in the wire rope removal from service criteria. If you identify any of these types of damage, remove slings from service immediately, even if the damage you see is not as extensive as shown. Once removed from service, destroy damaged slings and render them completely unusable. Never ignore sling damage or attempt to perform temporary field repairs of damaged slings. It is very important that slings get regularly and properly inspected. If you are not sure whether a sling is damaged, do not use it.

Hopefully these articles have helped drillers know what to look for in wire rope, how to decide when to replace it and what to document during an inspection.

Wishing all of you safety and health in these difficult times.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!