Upgrading an Early Water Well Drilling Rig

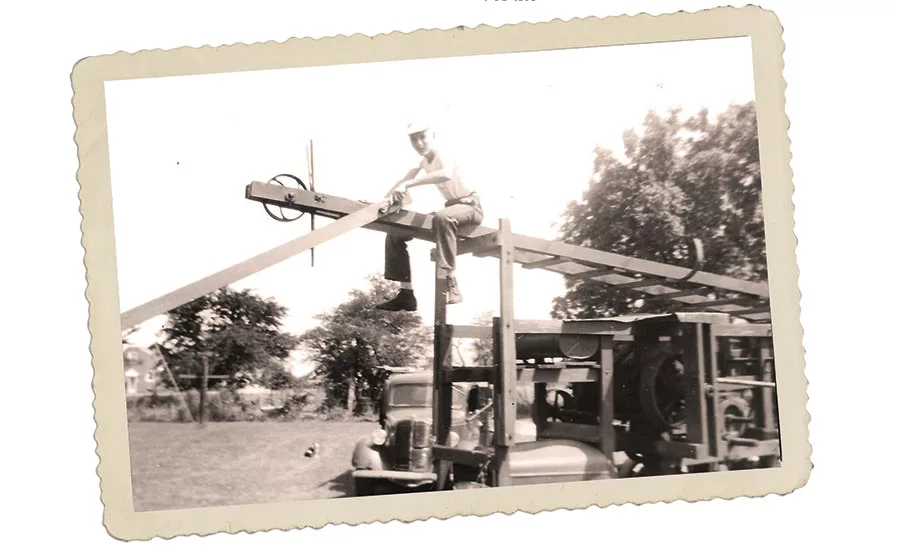

Columnist John Schmitt’s father spent years working on this makeshift rig before ultimately building one of his own in the early 1950s.

Source: John Schmitt photos

Schmitt, shown here at about age 13, with the family’s first rig and the 1937 Ford they used for support.

This column continues the tale of the ancient rig that I cut my teeth on in drilling. By the late 1940s, my dad had modified this original cathead-type rig. It had a bull reel with brake and clutch, and a spudder beam controlled by a jaw clutch.

This rig had always used 1-inch manila rope — sometimes called hemp. In the years after World War II, this rope and many things were hard to get in both quantity and quality. People tried a lot of new ideas to make up for shortages, some good and some not so good. My father found it increasingly difficult to buy serviceable manila rope. After two purchases that gave less than expected service, he complained to the hardware store where he bought it. They told him it was the best they could buy. He decided it was time to go to wire rope — or steel cable — as a drill line.

I don’t remember if we changed the sheaves or not. It seems to me we did. He fed the bull reel with either 7⁄16- or ½-inch wire rope. When we started the rig up the first time after making this change, it darn near shook itself to pieces. We did not have a shock absorber, and the mast and frame were absorbing all the shock of the wire rope. To solve this, he looked at commercially built machines and more or less copied the shock absorbers at the top of the mast. He did, however, use a coiled car spring as the shock absorber itself. This smoothed out the rig and we no longer had to wrap the manila hemp line onto the bull reel every night (where it was covered by a small roof). You can guess who got the job of restringing the spudder beam and the crown sheaves. It was yours truly.

The wire rope and shock absorber had a huge downside. The mast could no longer be erected by pushing on the mast support beams. The shock absorber assembly added just too much weight for two men to push the mast into a vertical position. To address this, my dad bolted steel angle iron, 4-by-4-inch as I remember, to the bottom end of the mast. He connected the two beams with another beam and hooked a six-part block and tackle to it. The block and tackle itself used probably ⅝-inch manila hemp. He attached the other end of the block and tackle to the rig frame, and now two men could raise the mast. On a roomy new well site, he would tie the free end of the rope to the bumper of the Ford pickup we used as a service truck. Backing the truck up pulled the mast into the vertical position quickly. After bracing the mast, I think we took the steel angle arms off but I frankly just don’t clearly recall.

With all the improvements made over time my dad now had a reasonably modern stroke-type machine. It was somewhat of a Rube Goldberg creation but it worked. (Goldberg, a well-known cartoonist and writer of that era, devised complicated and comic ways to do a simple job.) And we still had the towable car chassis, which made moving this rig an adventure.

The Rig at Work

My dad drilled 2-, 2½-, 3- and 4-inch wells by the hollow-rod method. The hollow-rod method, which I wrote about years ago, uses drill pipe down the hole to do the drilling. A hollow-rod bit at the bottom has a moveable ball in it that serves as a check valve. The up and down motion of the drill pipe actually pumps cuttings to the top where they go through a hose to a tub or barrel. As drilling progresses, the driller adds water from some outside source or, perhaps, the reused water the drilling provides.

My dad always pulled the drill pipe and then hooked onto a drive block to drive casing. In a well much deeper than 50 feet, this method became a real burden and a huge downside. For the 2-inch wells, he used 1-inch schedule-80 pipe. For the 2½-inch wells, he used 1¼-inch schedule-40 pipe. For the 3-inch wells, it was 1½-inch schedule 40 and for the 4-inch wells, 2-inch schedule 40. This 2-inch drill pipe was really beyond the capacity of this old rig. He only drilled a couple of shallow 4-inch wells.

The 2½-inch well was a goofy design, if ever. In that size, jet pumps that used a packer-type ejector had a much higher capacity with 1¼-inch drop pipe than the same pump on a 2-inch well with 1-inch drop pipe. The 2½-inch pipe could prove quite weak in the joints due to the thread size. Dad had some joint failures, which made this goofy size unpopular. Three-inch wells where we could use a flat-bottom bronze screen were a big step up. At the end of the jet pump era, the ones we installed were quite productive with a long life.

By the early 1950s, the submersible pump gained wider use. Although initially not as reliable, submersibles had far more efficiency than jet pumps. With the old car chassis rig wearing out and the growing popularity of larger wells, my dad decided he needed a bigger rig. He looked at several models at conventions, but ultimately decided he could make one. He started this in about 1950 or ’51. Next time, I will start writing about that rig, which we rather quickly changed into a cable-tool rig that served us well for many, many years.

The weather in Michigan this winter has been unusually warm and clear. As I write this in the middle of January, we have had a snowstorm overnight. The accumulation was not very heavy and my trusty John Deere with a snow blade and tire chains was ready to clear the driveway. As always, keep working hard, work safe and take some time to enjoy life.

For more John Schmitt columns, visit www.thedriller.com/schmitt.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!