Drilling Rig, Tooling Maker Talks Lessons from a Century of Business

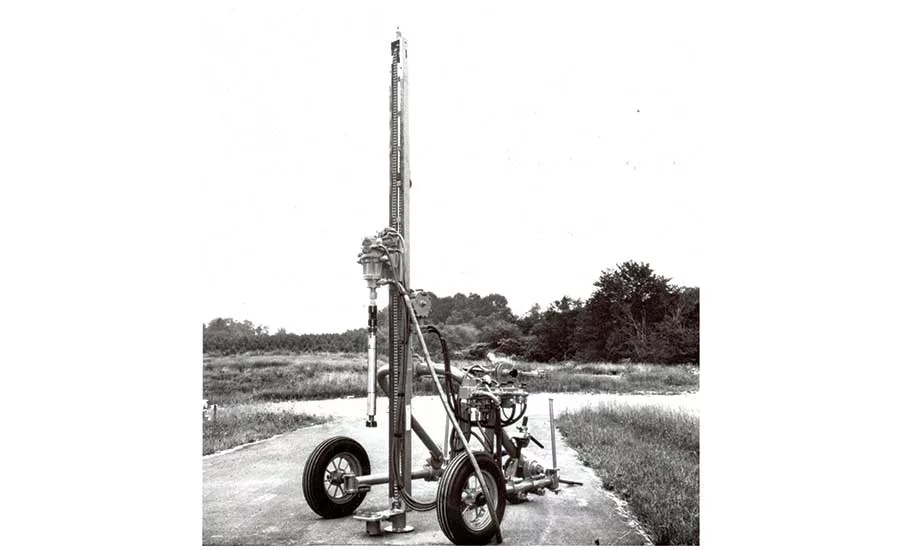

Acker Drill Company started as a contract drilling firm in 1916. Today, they make rigs and tooling for the geotechnical, environmental and mineral exploration markets. Source: Acker Drill Company photos

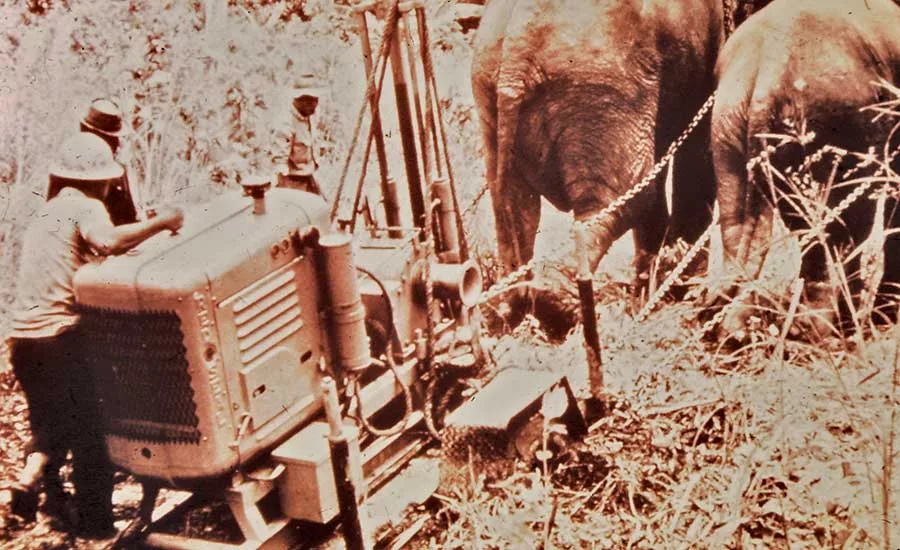

Acker rigs are sold all over the world. In this historical photo, one of the company’s rigs gets a helpful pull from a pair of elephants. Source: Acker Drill Company

Enterprising people start companies every day. Few of those companies make it to five years, let alone more than 100. They suffer economic trials, from downturns to full-blown recessions. There are supplier challenges. Customer needs change and evolve. Entire market categories shift. So, it’s important to celebrate companies that make it that far, and to hear what they have to say that can benefit other companies or would-be companies in the drilling space — whether those are manufacturers or contractors out on the jobsite.

Acker Drill Company is one of those enduring American companies, having last year celebrated a full century of business. National Driller spoke to Matthew Vass, their domestic sales representative and a second-generation Acker employee, about the company, its challenges and its successes over its long history.

Our conversation has been edited for space and clarity.

Q. First, can you give me a brief rundown of Acker’s 100-plus year history?

A. Acker was founded in 1916 as a contract driller. They were involved with investigating for anthracite coal. We are in the Scranton, Pa., area. We’re located in a suburb of Scranton, which is the anthracite coal region. (Editor’s note: Northeast Pennsylvania sits on the largest anthracite coal deposit in the world.) In the ’40s, anthracite coal took a dive and that’s when Acker parlayed into a manufacturer of drilling equipment — drill rigs, drill tooling. In the 1950s, that’s when Acker hit its stride with equipment. At one point during the 1970s, we employed over 200 people.

The original Acker family sold out in 1992. They were bought out by Christensen Boyles Company. Christensen Boyles sold in 1996 to Frank Gregory of Warren George. Warren George was one of the largest contract drillers on the East Coast — based out of New Jersey. He saved our company. Guys were given their pink slips when Christensen Boyles pulled out of Acker Drill Company. Mr. Gregory bought the plant and saved all the jobs and he owned it until 2006, until his death. Then his son-in-law Wayne [Wise] bought the place, and here we are.

Q. If you could boil down Acker’s longevity to one or two key reasons, what would those be?

A. Relationships and quality. Relationships for sure. I mean, Bill Jones, who passed away a few years ago, he was domestic sales representative for us and also our vice president for many years, he was instrumental in building a lot of our relationships across the country, internationally. So I give him a lot of credit in terms of how we conduct business in the office. We have a lot to credit Bill Jones with.

Quality, I mean our drill rigs — everybody seems to hold Acker to a higher standard. It shows in our drill rigs’ quality. We have a lot of versatility; that’s another reason for our longevity.

Q. Many of my readers are contractors, while Acker is obviously a manufacturer. That said, I’m sure you work closely with a lot of your rig-buying customers. How would you say succeeding in your part of the industry is similar to succeeding as a contractor?

A. I think it boils down to relationships. Relationships with people who operate our equipment, relationships with our distributors. I think it boils down to that. I don’t think it’s any different in any business; it boils down to relationships and treating people like you care, like friends or family. That’s how we conduct business. We’re on a first-name basis. Somebody buys a rig, we know the name of their wife, we know their children. We try our best to be as personal as possible.

Q. How does success as a manufacturer differ from success as a contractor?

A. As a manufacturer, our job is to provide people with what they’re asking for. We, at times, provide whatever guidance we can give. We have many, many years of experience here. But most of the time, we try to just provide people with what they’re asking for. Whereas a contractor, their job is to figure out how to complete a job, to take on a task.

Q. Both manufacturing and drilling contracting are capital-intensive. What financial strategies have helped Acker that other companies might benefit from?

A. In terms of that, we focus on what we do best. We don’t try to latch on to the flavor of the month. We keep doing what we do best, which is build drill rigs for the geotechnical, environmental, mineral exploration markets. We manufacture tooling for those markets. We don’t stray too much. We do custom projects from time to time for people, but we don’t try to overreach. We try to just do what we do best.

Q. So, just from a resources perspective, when you’re spending money or thinking about spending money to bolster a product line or create a new product, you’re coming back to “what is that core mission and how are we serving people?”

A. I would say that’s accurate. Absolutely.

Q. There’s a lot more to manufacturing than just making things. Any successful business needs a support team that might include lawyers, accountants, bookkeepers, marketing people, etc. Is Acker’s approach to have these positions in house or out, and why?

A. For the most part, all of those positions, our accounting, our marketing — I’m the marketing person, as well — sales, engineering — we have four engineers on staff, it’s all in house. For instance, engineering. We have four brilliant engineers on staff at all times. We’re not dependent on other companies, third parties, for engineering. So we’re never held hostage if we need a quick solution to a problem, especially out in the field or with a drill rig, or what have you.

Q. What’s one business lesson you see a lot of small business owners ignore or refuse to learn?

A. What we spoke about earlier: I put a lot of emphasis on doing what you’re good at and trying not to overreach. Don’t spread yourself too thin. We focus on our bread and butter. We focus on drill rigs for markets that we’re familiar with, and the tooling. We don’t try to overreach into other areas where it’ll stretch us thin and be detrimental in a lot of ways. I’ve seen it with other companies getting into other genres of even drilling, but they spread themselves too thin. I think we just stick with what we’re good at.

Q. What steps is Acker taking to position itself for the next 100 years?

A. Continue with what we’ve been doing: relationships, service. Continue the high quality on the drill rigs, continue our relationships with our distributors. We’re a small company with big capabilities, so we want to stay on that course.

Q. How long have you been at Acker?

A. This is my ninth year.

Q. Can you talk about a particularly challenging time in Acker’s long history, and how it overcame those challenges?

A. My father worked at Acker Drill for 48 years. He worked from 1963 until 2011. He’s still involved in the company is some ways. ... I’ve seen it. I remember in the ’90s, after Christensen Boyles pulled out in 1996, I remember it was slim here for a while. There were office employees actually keeping the shop running. We have an 80,000-square-foot plant, and we only had a few employees running it. From then on, we slowly grew and Frank Gregory, like I said, bought us in 1996, and his son-in-law bought us in 2006. Since Wayne [Wise] bought the place and Mike DiCindio, our vice president, took that position, we’ve grown and we’ve become stronger and now we’re a name to be reckoned with again.

Q. Acker has changed a lot over the years. Is it required for a lasting business to be flexible? Or can a company stick to its core mission and still succeed over the long term?

A. For us, fortunately, there were times we had to be flexible. Our industry, for the most part uses old technology. For instance, the split-spoon has been around for 50 years-plus and very little has changed. Until they unveil a better way to produce a soil sample and information for geotechnical, it’s going to continue to remain that way. For us, we just need to continue what we’re good at and to incrementally grow and expand our product line. We try not to take on too much too fast.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!