Home » Keywords: » drilling fluids

Items Tagged with 'drilling fluids'

ARTICLES

Clark County regulators say the company repeatedly dumped drilling fluids into manholes

Read More

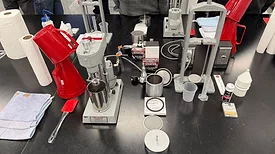

Mud School 101: Essential Training for Drillers

Is mud school necessary for the average driller?

Read More

Wyo-Ben Honored by Montana for Workplace Safety

Company Recognized for Dedication to Safe Operations

Read More

CETCO Rel-PAC Xtra-Low Certified to NSF/ANSI/CAN Standard 60

Polymer Designed for Borehole Stability, Lower Fluid Loss

Read More

Wyo-Ben Buys M-I Swaco Bentonite Operation

Company Says Purchase Positions it for Growth, Innovation

Read More

Dig deeper into the drilling and water supply industry!

Build your knowledge with The Driller, covering the people, equipment and technologies across drilling markets.

SIGN UP NOWCopyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing