The Art of Drilling: Mastering the Unknown Below

A Historical and Personal Exploration into the Ingenuity, Evolution, and Challenges of Subsurface Discovery

Drilling holes in the ground brings some unique challenges and a quirky attraction that are not common with other types of heavy equipment operation. When we drill into the ground, we drill into the unknown formation that lies beneath our feet. As we penetrate those varying formations, we prove the evolution of our planet and the different cataclysmic events that happened over millions or billions of years of time.

In these underlying formations are some valuable resources we can benefit from. These resources were unknown until discovered accidently or with deliberate intent as a hole was drilled into these underlying stratums.

The History of Drilling

In 1802 Joseph and David Ruffner used a Spring Pole Rig along with much ingenuity and innovation to dig a hole to 58 feet. It took them 18 months to complete the well for the needed brine they were searching for.

Image from “The World Struggle for Oil,” a 1924 film by the U.S. Department of the Interior.

Before refrigeration was available salt brine was needed for curing and pickling as a means of food preservation. Upon completion of this well, the Kanawha River Valley in West Virginia became very popular for salt manufacturing and distribution due to the Ruffner Brothers discovery.

A Spring Pole Rig has a hemlock or some type of flexible tree that has memory and springs back after being bent over. The trunk of this tree is anchored at one end and supported at an angle by a vertical post. At the live (action) end there's a rope extended down the hole with loops for stirrups for men to use one foot to kick it down. A drop weight is tied to the end of the rope at the bottom of the hole. The men each would have a foot in a stirrup and in unison would keep a cyclic rhythm technique of kicking the weight down to impact the advancing soils. The spring of the hickory would then recoil the weight making ready for another blow to again pulverize the soils. Bailing was needed periodically to clean the bore hole.

This was a percussion technique for hole processing. Rotary drilling came later which was attributed to the advancement of the steam engine to create both rotary and reciprocal motion. (Another story for another time.) Spring Pole digging is very slow and a labor exhausting process. The Ruffner brothers took the hole down to 58’ depth. Requiring casing for the upper 18’ then 40’ of rock spudding to TD.

We can only imagine the challenges and discoveries in both equipment and technique that were resolved during those times to complete a boring. They tried different timber to find the best type of tree for the longevity of the spring pole before it either breaks or loses its spring reaction. The type of rope that they utilized along with the design of the drop weight percussion tool. As the hole advances the tool wears down and loses its gauge diameter. Periodic build up or replacement was necessary to maintain proper hole diameter. Spring of the pole was often needed to unstick the tool as it wedged in the advancing formation. We can only imagine the job site accidents that may have occurred.

I find it sobering to reflect on our history to understand the amazing advancements that have been made. Some are the same challenges we deal with today. Everyday we face challenges, try to explore ideas and techniques which are needed for the evolution of technology to advance.

Water wells were shallow, large-diameter, hand-dug then lined with rock, timber or bricks of the time. These early well diggers used the shovel and pick axe along with other hand tools. Once completed water would then be retrieved with a bucket tied to a rope.

The Legacy of Innovation

Technology continues to advance as the driller explores and learns new ways to overcome challenges. Back in those early days, those challenges were issues that had to be resolved with natural material. The blacksmith was the craft tradesman who built tools for various applications. Providing food and water for family and community, being the most important of all. The young blacksmith John Deere was a smith in Vermont. When the rail was going through to the west John with his children and wife moved to Illinois to build farming tools for the new homesteaders to make their claims. Plowing soil was accomplished for centuries by pulling a stick with oxen in the wet spring soil. A farmer would walk 8 miles to plow an acre. Stopping to clean the mud cake of the plow slowed the process. John Deere found his fame when he repurposed a broken saw blade into a self-scouring plow blade. Being resourceful, trying something different and working the problem is the key to success

The primary and unique skill of a driller is the ability of down-hole problem solving in the blind. Equipment operators of a backhoe, excavator or a grader can all see their work and do it with hand-eye coordination. The driller does not see the tool. Like a blind person, their other senses are in tune more of what is happening downhole. This visualization technique is a very unique skill that drillers understand all too well. We detect what's going on down the hole by the response of the drilling tool — jump, lock up and rotation — by the sound of your engine loading up and by the material represented from the encountered formation as it is brought to the surface. Any change in tool response is an indication of changing formations. These transitional zones cause the tool to respond differently. It is by skillful determination that the driller recognizes and makes the necessary adjustments and changes to keep the hole advancing as intended.

Down hole visualization requires our constant and focused attention. The decisions we make may not always be the correct one. Mistakes happen, and through those mistakes we learn what not to do next time. The analytical approach to problem solving draws upon our experiences, resources, shared lessons from other drillers and the current technology available to overcome those downhole challenges. Continuing to try different approaches is critical to success. Through these discoveries is the growth and advancement of drilling technology.

The biggest joy is the satisfaction of completion which brings a rewarding sense of accomplishment. The more challenging wells enhance a higher degree of pride, adds to our experiences and builds team confidence in your crew.

Those of us who are drillers come into this industry one of three ways:

- You discover it by coincidence

- It discovers and attracts you

- You’re born into it.

As children we learn from our parents. When the dinner table conversation is about the drilling challenges of the day, we become intrigued and inspired. As we grow and want to earn money we go to work in the shop where we learn more about the trade every day.

Drilling is not a trade for everyone. With this title comes much responsibility. Continually servicing and maintaining equipment is critical. Long days, giving up a weekend when necessary. Supervising the crew, keeping everyone safe and productive. The down hole advancement of the tool and casing the bore hole or maintaining circulation when mud drilling is the task at hand and this is the one skill that makes us quite unique craftsmen.

There is no instruction manual on how to drill a hole. There's a manual on how to service and operate the equipment. Drilling the hole is something that you're going to learn by doing or from shared experiences of others.

There is no instruction manual on how to drill a hole. There's a manual on how to service and operate the equipment. Drilling the hole is something that you're going to learn by doing or from shared experiences of others.

With any project that we take on, we try to do it as efficiently as possible. We continue to analyze daily how to better optimize our process. How do we equip our team to be the most efficient and effective in the execution of their duties? How do we minimize the loss of resources, wear on tooling and equipment, don’t waste money and most importantly optimize our time? Time is the most important resource that we have so we need to make sure that we make the maximum use of it. 12- to 14-hour work days were common. I recall roughnecking as a floor hand on a double. Pulling seven 12s till the job was done. Earned lots of money with no time to spend it.

The Most Valuable Resource We Have is Time

The valued time should be with family and friends. We work to live rather than live to work. Our world is a constant amazement of discoveries. As drillers we penetrate hidden formations that may have been once on the surface millions of years ago. Plate tectonics, volcanism, water erosion and sediment continue to change our topography. In the early 1990s I was well drilling in the Clark Fork River valley in Montana, east of Pend Oreille Lake.

The typical practice was roller cone drilling and banging casing till I tagged rock. Set the casing then tripping out to change to a down hole hammer to penetrate the shale formation searching for water intrusion fractures. I’d be hammer drilling for 20 to 40 feet then bust out of the rock back into alluvial material.

Starting with larger diameter casing then reducing as these gigantic boulders were encountered was one technique until the under-reamer was introduced. I’ve run many variations of under-reamers. Some are better than others and they improved and perfected over time. It is interesting to see a technique from one drilling practice make a lateral jump into another.

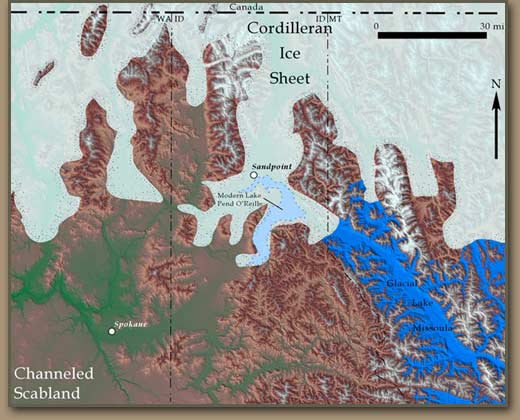

Image Illustrated by Bruce Bjornstad

Example: Horizontal boring both pushes and pulls advancing rings as the horizontal bore diameter increases. It took an idea and discovery to adapt this into vertical drilling by introducing the disposable ring bit. This along with a hydraulic casing driver tooled up on my Speedstar drill would go and burn 300 to 400 feet of 6” casing regularly. Pop off the ring, trip out then perforate the casing made for some great water wells in this challenging ground formation.

I wondered, as we drillers do: How did all these huge building-sized boulders get buried in hundreds of feet of gravel and cobbles? Through some research I learned about an ice dam that held back Glacial Lake Missoula 12,000 to 15,000 years ago. A long time ago? Not very for a planet that is 4-1/2 billion years old. The ice dam was over 2000 feet tall. The lake was as big as Lakes Erie and Ontario combined. When the dam broke each time, it would erode soil and rock on its race to the Pacific Ocean. Those huge boulders were evident of the power of kinetic energy as this wall of water traveled at high discharge volumes that made the modern day gorges, lakes and aquifers of the Pacific Northwest.

The History of Drilling is Not Over…

We see it in a short glimpse of time, but even in my 40 years I have witnessed the forward advancements in this industry firsthand.

Each one of us who drills holes in the ground are still contributing to this technological advancement. Overcoming challenges and facing adversity are the two quintessential elements of humanity.

What problem will you be faced with? What tools and ideas do you have? What new discoveries will you find?

Keep turning to the right, stay safe and win the day!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!