Standards and Compatibility in Drill Pipe Connections

Making Sense of Gauge, API and the Threads We Depend On

If you’ve benefited from standardized drill pipe connections — and if you’re a driller, you have — you have the American Petroleum Institute (API) to thank.

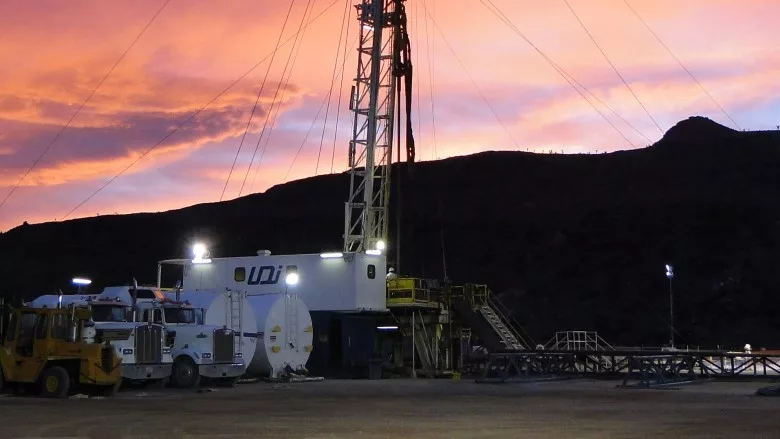

Source: U.S. Department of Energy

When teaching beginner beekeepers, I suggest that they try to buy all hive components from the same source. Although different manufacturers follow the important basic dimensions of their hive bodies (the boxes we’re all familiar with), any variances can have a significant effect on how bees react and build their pathways when we stack the bodies in a hive. So, as drillers, why does it not matter from which reputable drill string manufacturer we buy and be confident the connections on my drill pipe, subs, and hammers are all compatible?

First, the solution to the compatibility issue was developed (and is continually tweaked) by the American Petroleum Institute, better known as the API. The group maintains standards for Regular (REG), Internal Flush (IF), Full Hole (FH) and Numbered Connections (NC) threads. They set the design of the individual connections and monitor the thread gauges used to verify that the connections are good once they pass the dimensional requirements. Once a thread is machined, it is gauged as a final test.

These gauges are hardened and ground to ensure accuracy and durability. They are rather expensive to buy and they must be maintained. When you consider all the Reg, IF, FH and NC connections, it results in a hefty investment. Many manufacturers often include non-API connections, such as BECO, H90, Mayhew, FEDP, H90, Cubex and others. That is a major investment.

When I first entered this industry, we had a good collection of hardened ground gauges for the API connections. In instances where we lacked an official gauge for a particular thread, we used a “size piece”. A “size piece” is just a sample connection. You screw it onto your newly machined connection, and make sure it shoulders and is not too sloppy when you back it off a little. Definitely not as precise as using a thread gauge (from which you get an accurate, measurable result), but better than nothing.

I remember our 6⅝ REG pin size piece. This was the pin connection on tricone bits like a 9⅞- or 12¼-inch diameter. We cut a 6⅝ REG box primarily on bit subs and stabilizers. We literally made our size piece by cutting a pin from a tricone bit, including about an inch of shoulder. I think it was likely a used bit at that.

As business owners, we wrestle with tough decisions about where to spend our investment money. … We usually want our investment to have a return. Does it make you more profitable or increase incoming revenue?

When I became responsible for such things, I made it my goal to upgrade our gauge inventory. Slowly, we replaced size pieces we had with official thread gauges.

As business owners, we wrestle with tough decisions about where to spend our investment money. Maybe you consider a new facility, a facility expansion, a new rig, adding personnel or expanding your capabilities. We usually want our investment to have a return. Does it make you more profitable or increase incoming revenue?

When I decided in replace that 6⅝ REG size piece with an official, hardened, ground thread gauge, it cost well over $5,000 (in 1985 dollars). Not a huge investment compared to most, but it was one with no real monetary return. We were not having problems with that thread. It would not make us more efficient. It would not increase our profits or income.

It did provide for peace of mind. At the time, we were getting more involved in the construction aspect of drilling. Twelve-inch hammers and larger were becoming more popular, along with canister rods. Our 6⅝ REG connections, in the field, would face much more tensional and torsional stresses than when they connect with just tricone bits.

This was just one of many gauges we needed to eliminate the use of size pieces. Combined, it was a large investment. In a sense, it was like improving our infrastructure. You need strong infrastructure to not only build a business but also provide a foundation for expansion.

We can thank the API and people serving on the group’s many committees for connection standards that exist today. Over one hundred years ago, the API was formed to standardize the oil and gas drilling industry. These standards have since been adopted by water well, mining, construction and other drilling sectors. Check out their website at www.api.org.

How is your infrastructure? What large or small investments are on your wish list?For more Pipeline columns, visit thedriller.com/pipeline.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!