Water, Graphite and Geothermal Grouting (Take 2!)

Make Your Mixes Easier by Pre-Measuring Water, Marking the Grouter

To ensure a proper mix, contractors can weigh out water in a jug and mark it for measuring. Then, once they have the required amount of water in the grouter, they can mark that too.

Source: CETCO Drilling Products

In summer 2020, I wrote an article for The Driller titled “Water and Graphite: A Geothermal Game Changer.” In that article, I discussed the effects on geothermal mixes utilizing graphite vs. sand. Here is an excerpt from that article to refresh the reader’s mind:

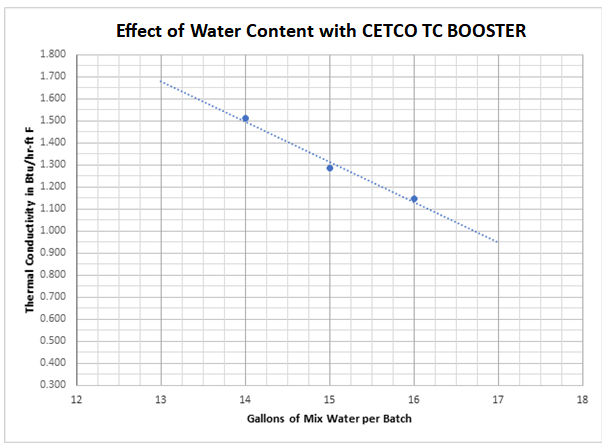

Manufacturers of geothermal grouts found out early that graphite is a “big lever” in a geothermal mix. This means that only a small amount of graphite increases the TC value dramatically. The amount of water in the mix directly affects the swing of the graphite lever — that is, the thermal conductivity — in an unexpectedly large way. In a typical graphite-containing mix, increasing the water by 1 gallon will see a reduction of thermal conductivity of up to 15%. That means if you are supposed to be adding 15 gallons of water to your mix and the actual amount is 16-gallons, an expected 1.2 TC value may test at 1.02 TC. Likewise, decreasing water by 1 gallon will send TC values the opposite way.

The chart with this column shows the effect on TC values as water is added or removed from a mix. The chart assumes a normal mix of 50 pounds of geothermal grout, 24 pounds of graphite flakes and 15 gallons of water — a mix that produces grout with a 1.2 TC value. Note the large TC changes when adjusting the water in the mix by small amounts.

Click the image for greater detail

A small increase of water will not only change the expected thermal conductivity, it will affect the suspension, setup time and permeabilities downhole. Our research and development technicians work hard to get the optimum grout/graphite/water mixture for each TC value range. For this reason, we publish the complete mix, including water amount, in our Technical Data Sheets (TDS) and online Geothermal Calculator results.

Last summer’s article provides three methods for ensuring the proper water amounts in the mix: weighing the water with a scale, using a water meter and hand measuring the water with a measuring cup. In our normal grouting world, we are used to 24-gallon requirements — not so much the 15-17 gallons needed for the new mixes. Checking and marking the grouters is important to ensuring consistent mixes throughout the job.

After that article published, I went into the field on a geothermal job that required 1.9 Btu/hr/ft/F. The contractor did not have a water meter on site but assured me his driller “was very good and would get the water right.” I promptly built a calibration jug. I trusted his driller’s instincts and respected his years of industry experience, but I was curious to see how close he was.

Using 8.34 lbs./gal., the weight of water, I built the pictured water jug in my kitchen weighing each gallon of water needed. The CETCO 1.9 Btu/hr/ft/F mix uses 17 gallons of freshwater per batch. For this mix, I use my jug to add three jugs filled to the 5-gallon mark plus 2 extra gallons (also marked at the bottom of the jug. After I measure this, the grouter is marked for all future batches (one and done).

Check out more drilling fluids tips

When marking up this jug, I had to do my 1-gallon and 2-gallon weight measurements three times. They were not matching up to where the molded jug markings were. When you make your own, I suggest measuring several times to verify. As I wrote, being wrong about the amount of water by even just 1 gallon (either way) can change thermal conductivity up to 15%. Check and mark that old grouter you use. If you buy a new one, recheck and remark it. When working with graphite, the proper amount of water ensures success!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!