Water and Graphite: A Geothermal Game Changer

For Makeup Water, Think about Quantity

Manufacturers of geothermal grouts found out early that graphite is a “big lever” in a geothermal mix.

Source: CETCO Drilling Products

It seems like “mud folks” always talk about water. The quality of makeup water for drilling fluids is a reoccurring topic of mud schools and articles. You occasionally see eyes rolling when the topic of water comes up, so I am not going to discuss that kind of water. This article will relate to geothermal mixes and water’s role in the quality, pumpability and final thermal conductivity (TC) of mixed geothermal grout.

When we first started teaching geothermal grouting classes, we focused on sand quality. We recommended round grains of uniform size with moisture content of <0.1% (in a perfect world). For those of you using sand or sand/graphite combinations today, we still recommend this. However, more and more we see sand take a backseat to graphite products as the “new” additive, and as a thermal conductivity (TC) booster. This is perfectly understandable, as engineers and system designers seek higher (TC) values in their mixes — up to 1.9 Btu/hr/ft/F value — but still want pumpable, easy-to-install grouts.

A small increase of water will not only change the expected thermal conductivity, it will affect the suspension, setup time and permeabilities downhole.

We now focus our grouting classes and jobsite visits on water, that mundane ingredient we add to our geothermal grout mix. While the quality of the bentonite grout and graphite are important, they are not the culprit in most of the issues we find on geothermal projects. Water quality, while also a factor, is not the focus either, since most of us know to use a trusted quality water source like municipal or a local water well. Our focus on water is the quantity in the geothermal mixes we pump.

Manufacturers of geothermal grouts found out early that graphite is a “big lever” in a geothermal mix. This means that only a small amount of graphite increases the TC value dramatically. The amount of water in the mix directly affects the swing of the graphite lever — that is, the thermal conductivity — in an unexpectedly large way. In a typical graphite-containing mix, increasing the water by 1 gallon will see a reduction of thermal conductivity of up to 15%. That means if you are supposed to be adding 15 gallons of water to your mix and the actual amount is 16-gallons, an expected 1.2 TC value may test at 1.02 TC. Likewise, decreasing water by 1 gallon will send TC values the opposite way.

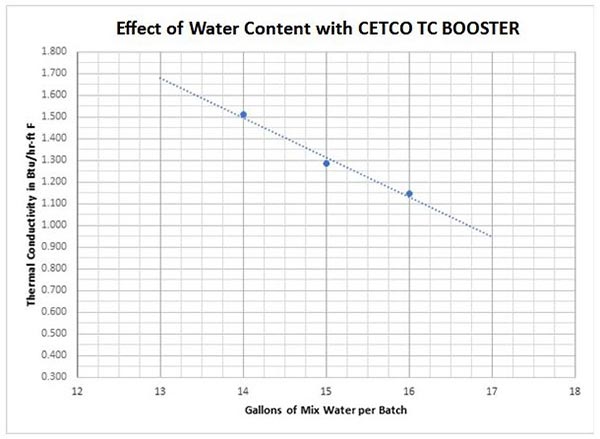

The chart below shows the effect on TC values as water is added or removed from a mix. The chart assumes a normal mix of 50 pounds of geothermal grout, 24 pounds of graphite flakes and 15 gallons of water — a mix that produces grout with a 1.2 TC value. Note the large TC changes when adjusting the water in the mix by small amounts.

A small increase of water will not only change the expected thermal conductivity, it will affect the suspension, setup time and permeabilities downhole. Our research and development technicians work hard to get the optimum grout/graphite/water mixture for each TC value range. For this reason, we publish the complete mix, including water amount, in our Technical Data Sheets (TDS) and online Geothermal Calculator results.

There are three ways to assure your water calculations are spot on.

- Weigh the water using a scale. At 58 degrees Fahrenheit, the temperature underground, one U.S. liquid gallon of fresh water weighs 8.334 pounds (lb) or 3.780 kilograms (kg). For a 15-gallon mix, weigh out 125.1-lbs of water into your mixer and mark the water level for future batches. It is useful to note that the density of water increases as temperature descreases, with a maximum of 8.34 pounds/gallon at freezing and 8.27 pounds/gallon at 110 degrees Fahrenheit. This means that, based on weight, on hot days you are adding less water and on cold days you may be adding slightly more, because the water is denser when cold.

- Use a water meter with accuracy rates of +/- 1.5%. We have seen some less expensive water meters vary in accuracy, so beware.

- Hand measure the required water per batch into your grouter. Once you are sure of the measurement, mark the grouter and use that level for future batches.

Taking the time to check your water levels will pay off for future jobs. You may be surprised at your result versus expected results. If, in the past, your TC value was off from the published target, you may have been the victim of the Big Lever.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!