How Does Uphole Velocity Work for Drilling Jobs?

Oh great, another uphole velocity (UHV) article. I first learned about UHV from a young fellow by the name of Doug Black. I had been manufacturing drill rods and accessories for 15 years, but had never delved into the use side of the business.

Doug’s presentation was about drilling 12¼-inch holes using 10¾-inch drill pipe in a blasthole situation. At 10¾-inch outside diameter (OD), the new drill pipe produced a nice feet per minute UHV. As the drill pipe wore, its diameter decreased, increasing the annulus and, thus, decreasing the UHV. Here, OD wear might determine that the drill pipe needs replacing – not because the wear is making it weak, but rather the wear reduced the UHV too much. So, in blasthole applications, UHV is important not only in the design process, but as a factor in everyday monitoring of drill pipe life.

There are two factors in determining UHV. One is the cfm. Your compressor might be rated at 900 cfm. I am not an air guy, but understand that this number is theoretical and actual cubic feet per minute can be up to 15 percent less than the equipment is rated. Your compressor/rig seller should be able to offer good guidance.

When Doug and I were working together, our bit salespeople would use an air test kit that threaded into the sub and measured the actual cfm at the bottom of the drill string. Talking blasthole, sometimes the drill string is one piece of drill pipe and the bit sub. That was done because we needed to base our calculations on the actual air exiting our drill string and we needed to figure in any possible restrictions.

Bit people care a lot about UHV because too little cfm means cuttings are not properly removed and the bit regrinds these cuttings, which increases bit wear. When that happens, the driller typically gives the bit salesman the evil eye.

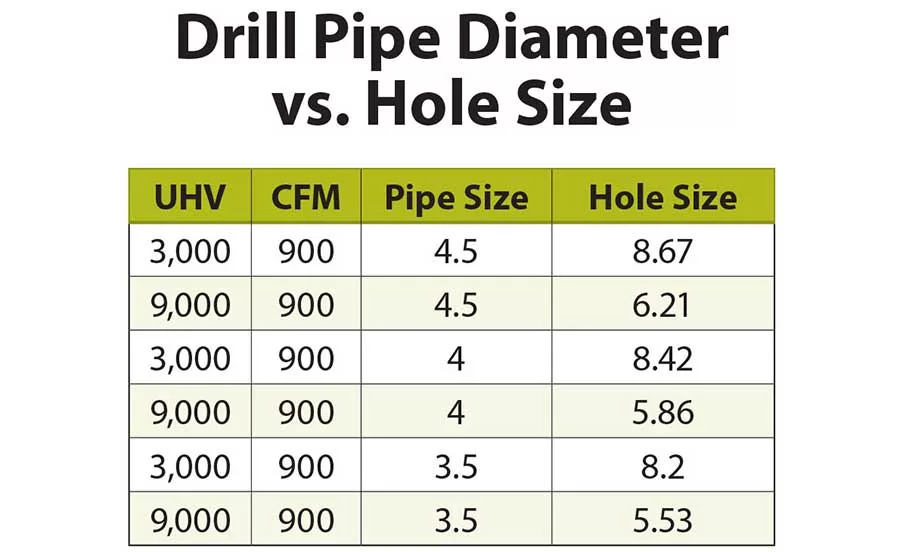

But bit wear is just one important aspect of UHV. The other is what happens with too high a UHV. High UHV can lead to hole degradation. It also increases the sandblasting of the drill pipe. Good for me, not so much for you. And it can affect hammer performance. At one time, the recommended UHV range was 3,000 to 7,000 feet per minute. Today, it seems to be 5,000 to 9,000 feet per minute. I typically go with 3,000 as a minimum and 9,000 as a maximum.

Let’s talk about down-the-hole (DTH) hammers. They can put a restriction in your drill string, and you need to figure this in when calculating UHV. Each hammer manufacturer assigns its hammers a “consumption” rate. This is the most air that can pass through the hammer. When calculating UHV, you need to use the lesser of the consumption rate or the actual air from the compressor.

Another factor in UHV is the hole annulus in square inches. This annulus is the area between your drill pipe and hole edge. This has an inverse relationship with the cfm. The larger the annulus, the less the UHV (cfm remaining the same). The annulus is determined by the area of the hole minus the area of the drill pipe. This might help you decide between running an oversized bit on your 6-inch hammer or biting the bullet and buying an 8-inch hammer. When making that decision, contractors typically think about warranty, penetration rates and cost, but should also consider the increased consumption rate of the 8-inch hammer. The restriction in that 6-inch hammer may mean added fluids to clean an 8¾-inch hole, but the 8-inch hammer with the larger consumption rate could permit cleaning with just air.

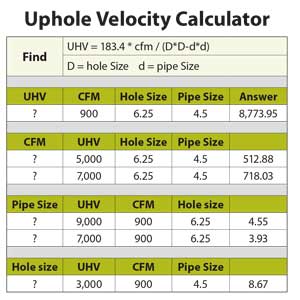

Here is the formula to calculate UHV:

Here is the formula to calculate UHV:

UHV = (183.4 * cfm) / (D2 - d2)

In English, that’s 183.4 times the cubic feet per minute divided by hole size in inches squared minus drill pipe diameter in inches squared. OK, it’s a little complicated, but easily built into any spreadsheet. We can manipulate this equation to answer some questions that might pop up when thinking about future projects. These might include:

- What is the largest hole I can drill using just air?

- What is the smallest hole I can drill without exceeding recommended UHV?

- What is the optimal drill rod size for the bulk of the work I want to do?

- I have a huge geothermal ground loop project to bid on. Is my drill pipe size OK, or do I need to factor in a different size drill pipe?

- How much cfm do I need to drill this size of hole?

I seriously doubt you want to read about algebra and relive those ninth-grade nightmares, so I will just say that I have all of this on an interactive spreadsheet that I can send to readers on request.

As an example, rather than calculating various hole sizes to see if the UHV is good, we can ask, “What is the largest hole I can drill using just air and my existing compressor and drill rods?” If we have a 950/350 compressor running 4½-inch drill pipe and a 6-inch hammer, and if we use 3,000 UHV as a minimum, then the largest hole using just air is 8 ⅜ inches. Ask that same question with a 1,250 cfm compressor, and the answer is still 8 ⅜ inches with a 6-inch hammer, but over 9 inches with an 8 -inch hammer thanks to increased consumption rate.

With the same setup, except using a 5-inch hammer, what if we get a call to drill some 5½-inch holes? Should we do it? What is the UHV? Will it be too high and wear out the drill rods and degrade the hole? Too much UHV can also negatively affect hammer performance. Will this job eat our lunch?

Let’s look at this idea that hammer performance can suffer if the UHV is too high. In these cases, we have a lot of “air energy” being used to get this air up the hole instead of running the hammer. My friend, Derek McIntyre, of Hamaman Inc., told me about a case where a customer was drilling holes using 3½-inch drill pipe. They were not happy with the rate of penetration (ROP). After looking over the situation, he switched them to 3-inch pipe and their ROP went up because it increased the annulus and lowered the UHV into a more acceptable range.

Rig manufacturers and hammer people have designed their tools to work in most applications. DTH consumption rates typically keep us in line when we have lots of air. This has allowed us to ignore UHV for the most part — and successfully — as long as we keep within the assumed parameters.

At one time, if you drilled a 6¼-inch hole, you used 4½-inch drill pipe. Larger capacity compressors now mean a lot of 6¼-inch hole is drilled using 3½-inch drill pipe. Why not? It is lighter and cheaper. Not so good when looking at those 8¾-inch holes, but a lot better to dip down to drilling 5½-inch geothermal ground loops. Knowing about UHV will help you make good decisions going in rather than saying, “Wow, I’m not taking any more of those jobs” after struggling on one jobsite.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!