How Does MMO Work for HDD Drilling Jobs?

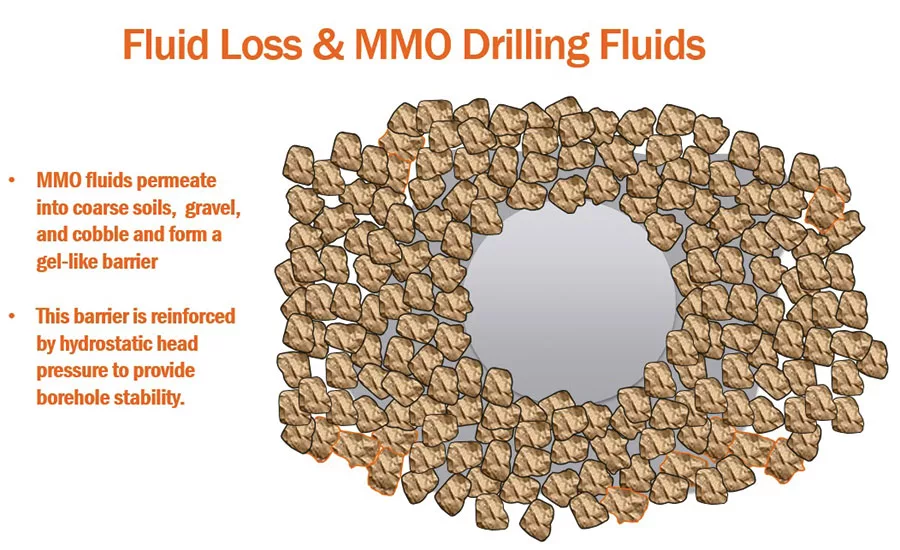

MMO fluids permeate into coarse soils, gravel and cobble and form a gel-like barrier. This barrier is reinforced by hydrostatic head pressure to provide borehole stability. Source: CETCO Drilling Products images

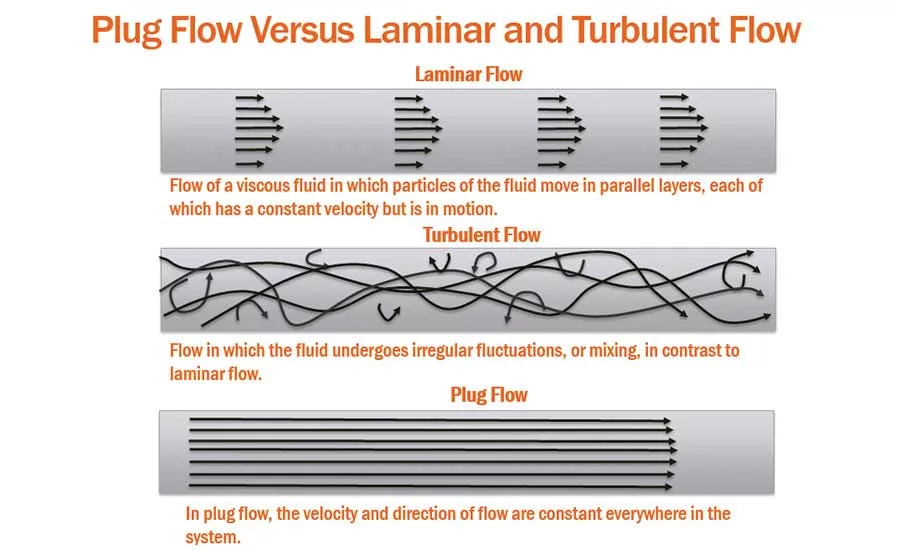

Unlike laminar and turbulent flow, in plug flow, the velocity and direction of flow are constant everywhere in the system. Source: CETCO Drilling Products images

The biggest difference between drilling fluids for vertical rotary mud drilling and horizontal directional drilling (HDD) applications is in the requirements for gel strength. In vertical rotary mud drilling, gravity is pulling the solids downward while the flow of drilling fluid is in the opposite direction. Therefore, if the annular ascending velocity of the drilling fluid is faster than the settling rate of the drill cuttings, the drill cuttings are carried out of the hole. Things become much more complex in the world of HDD. Where the flow is horizontal and the force of gravity is perpendicular to flow, annular flow rates are much lower, and drill cuttings have only inches to fall before they hit the bottom of the hole. While xanthan gum products are most commonly used to increase gel strength/suspension in bentonite HDD drilling fluids, while also keeping viscosity down, mixed metal oxide products are becoming increasingly popular in difficult drilling conditions such as gravel or cobble.

Mixed metal oxide (MMO), a mixture of magnesium/aluminum oxides and alkaline salts, has a layered crystal structure that closely resembles the platelet structure of Wyoming sodium bentonite. MMO is positively charged (cationic) while Wyoming sodium bentonite and most all of the polymers and additives used in bentonite drilling fluids are negatively charged (anionic). Bentonite/MMO drilling fluids can create tremendous gel strengths in order to suspend heavy drill cuttings, while minimizing viscosities and annular pressures because of the unique shear-thinning characteristics this type of drilling fluid is known for. A bentonite drilling fluid is non-Newtonian because, unlike water or oil, the viscosity of a drilling fluid changes with shear instead of temperature. The faster a bentonite drilling fluid moves, the thinner it gets, and when at rest, bentonite drilling fluids form a gel structure that prevents drill cuttings from settling when the mud pump is turned off. MMO drilling fluids take this principle to the extreme in that a MMO drilling fluid forms much higher gel strengths while being far thinner when it is in motion (which equates to lower pumping and annular pressures).

As previously mentioned, MMO is positively charged, therefore it works best with straight 90-yield bentonite. Newer blends of MMO are more tolerant to high-yield bentonite and even HDD specialty drilling fluid products. Anytime additional polymers and additives are used with a bentonite-based MMO drilling fluid, the benefits of using the MMO product are diminished. Fortunately, a good bentonite-based MMO drilling fluid has its own unique way of creating filtration/fluid-loss control and fluid-loss additives such as PAC polymer are unnecessary. Unlike conventional drilling fluids which (ideally) flow in a laminar flow (different layers of fluid moving the same direction at different speeds), MMO drilling fluids move in a plug flow (the fluid moves through the hole like a solid tube). As an MMO fluid penetrates into a coarse formation, it gels and creates a seal/ barrier that provides borehole stability. The only significant fluid movement in the borehole, while flowing, is a thin layer of fluid against the walls of the borehole as the return flow progresses through the borehole.

Because of the unique characteristics of an MMO drilling fluid, many conventional methods of testing drilling fluids, such as a viscosity funnel and cup and/or a rheometer, are pretty much useless. Gel strength indicators such as a shearometer can help provide useful information with MMO drilling fluids. MMO drilling fluids are also compatible with drilling fluids recycling systems. When correctly formulated, an MMO drilling fluid has the appearance of a drilling fluid that was way overdosed with bentonite, and in seeing this many contractors have a tendency to want to thin it back with water (avoid this temptation). Although the fluid may have the appearance of pudding, it is not unusual to have mud pump pressure readings that are half the pressure of conventional bentonite drilling fluids.

Extreme soil conditions such as gravel or cobble require extreme gel strength to suspend and carry out cuttings, especially in horizontal directional drilling applications, and that’s where MMO drilling fluids come into play. MMO drilling fluids provide second-to-none suspension/gel strength while minimizing annular pressures.

MMO drilling fluids are very different from conventional bentonite drilling fluids, and can be challenging for first-time users. First-time users of MMO should utilize the technical expertise of their drilling fluids manufacturer’s representative in order ensure success.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!