Looking Back at the Innovations of Drilco Industrial

Columnist David King says many of the innovations made by engineers at Drilco Industrial in its heyday still haven’t been topped.

Source: David King

I started in this industry in 1975 with a manufacturer of drill string components, including drill rods, subs, stabilizers, etc. We made products for rig manufacturers according to their drawings, as well as for distributors and drilling companies. We made a good product … but we were just manufacturers. We copied. We did not engineer. We did little innovation.

Today, I want to talk about a company that was innovative and designed many of the tools we still use. Perhaps it was the last of its kind.

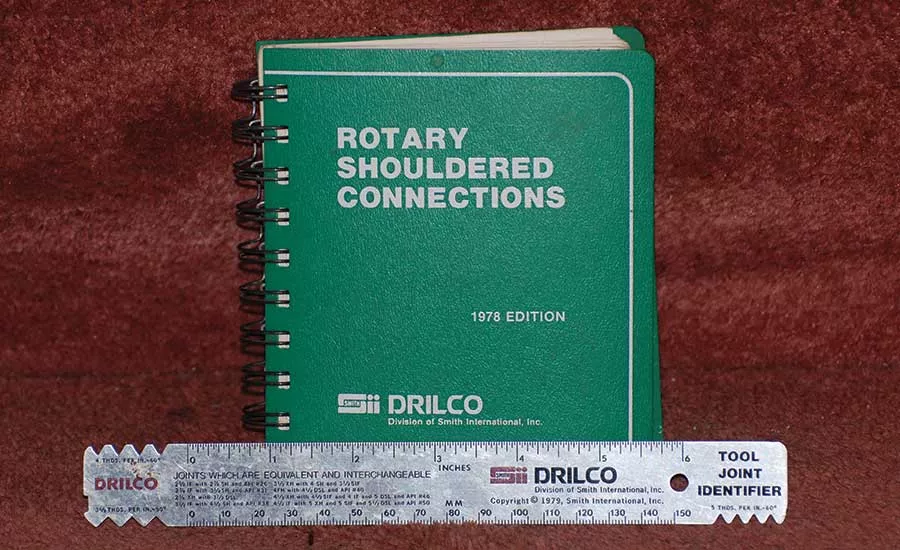

Drilco Industrial in Midland, Texas, was an industry leader in design and engineering. They were in their heyday in the ’60s and ’70s. They were split off the Drilco company that designed and manufactured for the oil and gas sector. Drilco Industrial concentrated in mining and other industrial uses, such as water wells and construction.

We are all familiar with the BECO (Bucyrus Erie Company) thread. Bucyrus Erie manufactured behemoth drill rigs that ran 13-inch drill pipe in doubles to run in a 65-foot single-pass operation. They provided a rough design for their new thread and then had Drilco Industrial apply the necessary engineering expertise to produce the BECO threads, which are utilized primarily in mining with tricone bits. Many OEMs came to Drilco Industrial for engineering advice, as well as for connections and drill pipe.

The famed 63B roller stabilizer is often copied throughout the world and used in many mining applications requiring larger-diameter hole sizes. Using it helped keep bits centralized in the hole, allowing for better bit life.

The Bit Buddy stabilizer allowed for replaceable sleeves to reduce the cost of stabilization for a straight-blade application. This design is still copied and utilized today.

The Model 60 reamer is another Drilco product still in use today. The Model 8750 and 8760 shock subs are still manufactured. Here, the team of engineers at Drilco tapped into a design utilized by the propeller drive systems in nuclear submarines. What ingenuity! The use of this shock sub helped protect the top drive mechanisms from suffering the vibrations and impacts from the bit doing its job.

In raiseboring, the DI22 series of connections still rule that market today. Their concept has now spread to the HDD market, helping drill pipe survive drilling during pullback. We think of drilling by pushing; drilling by pulling is a brand new ballgame for thread stresses. Drilco Industrial solved this.

Manufacturing methods like the Short Tang for heavier-wall blasthole drill pipe are still utilized today. Drilco Industrial not only designed products, but designed the manufacturing techniques to build them.

The products were not just innovative, but were backed by an exceptional quality assurance program and workmanship.

In those days, engineers from various rig manufacturers and Drilco communicated freely. As salesmen and management from these companies fiercely competed with each other, this group of engineers were all friends trading information and helping each other. I used to tap into that community. A community that, like me, has aged.

In 1990, Drilco Industrial was pieced out in auction due to suspected corporate mismanagement. Later that year, I went to work for Thompson International, which had purchased some of the Drilco Industrial equipment and the company name, as well as hired some of the personnel.

Because of this, I had the privilege of working with some of the Drilco Industrial people. Richard Melvin was part of that engineering team and a literal vault of information. Lupe Padilla covered Central and South America sales, bringing in orders from the famed copper mines of Chile. James Sepcar, one of the smartest people I have ever met, worked in designing tools and methods. He and I worked at the factory in Kentucky. Don Thompson and Susie Givens had put together one of the most knowledgeable and finest manufacturing facilities for drill string components that I have ever known. But things change.

Most of us have gone off in our own direction. Susie and I each have our own companies and remain good friends. Richard, who taught me so much, is semi-retired, but still active in advising the current Drilco sales team. Lupe is still pushing drill pipe, but now for another company. We lost James not too long ago. And Don Thompson died shortly after I put this together. There are a few other Drilco people from that era around in various locations. And Drilco Industrial still exists, but not at the level it once was.

It has been 28 years since that auction. BECO threads still rule when it comes to blasthole drill pipe. The DI22 still rules raiseboring. The 63B is still the one for bit stabilization. No one has come up with anything better.

Did industry engineering just stop? Are manufacturers settling for what is out there? No. I like to think it is just because that engineering team and their most excellent designs have yet to be beat. I am very fortunate to have known these people, and these were great friendships that are still great friendships.

As we travel through life in this industry, we find people that influence us and help chart our paths. They help us learn and give us their knowledge at no cost. I will mark my 43rd year on June 2. I value these people. Some are no longer with us, but I think about them and appreciate all they did for me and for the others who bothered enough to learn. To those who are still kicking, thank you.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!