Five Facts to Keep Drilling Jobs Simple, Productive

Whether horizontal or vertical, drilling contractors can get the most from their drilling fluids by keeping a few important tips in mind.

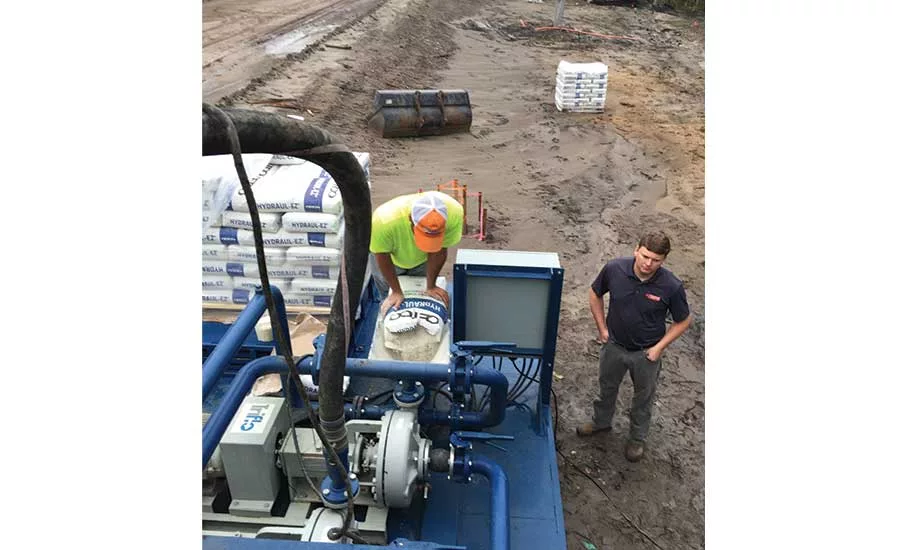

Source: CETCO Drilling Products photos

Most everyone has heard the acronym KISS and knows generally what it stands for: keep it simple, stupid. Or, how about “keep it short and sweet”? Or “keep it short and simple”? There are many iterations for the saying, but I think it’s safe to say we get the point.

We, as mud/fluid engineer types, tend to get a bit on the windy side when discussing how something works. In this article, I want to boil it down to five basic facts and discuss the options available to the drill contractor when they encounter hard-to-deal-with soils. These soils can be anything from sticky, swelling clays and shales to fine, medium or coarse sands and cobbles. Now, we don’t need a Ph.D. in polymer science to figure out which additives to use. Experts already figured that part out years ago. My goal is to explain which polymers deal with which soil types and … to keep it short and simple!

Fact 1: Mix Water/Drilling Fluid

Before we move to the specific polymers and additives, we need to briefly discuss the main part of any bentonite-based drilling fluid: the water and the bentonite.

The most basic drilling fluid is powered high-yield Wyoming sodium bentonite mixed with water. Please note that mixing water is 95 to 98 percent of the mixture. Adjusting the pH and water hardness of your mix water with soda ash will allow the bentonite and polymers to mix to their full potential. The mix water should have a pH of 8.5 to 9.5. If you’re not sure and don’t have the sample strips or equipment to check, simply mix .5 pounds of soda ash per 100 gallons (5 pounds per 1,000 gallons). This will ensure you have the best chance of success.

Fact 2: Clay Polymers, Dispersants/Thinners

There are several ways to handle reactive soils (clays). They react with water and cause sticky, swelling conditions, as well as bit balling and torque problems.

Synthetic polymers: These polymers, which are often referred to as PHPAs (partially hydrolyzed polyacrylamides), are long-chain, high-molecular-weight polymers manufactured in liquid or dry form. Liquid PHPAs are designed for fast field mixing, viscosity building and clay/shale stabilization by encapsulation. These long-chain, high-weight polymers wrap around the soil/clay particles and keep them from getting wet. Also referred to as inhibitors, these polymers inhibit the ability of clays and shales to absorb water.

Thinners/dispersants: Thinners and dispersants break down clays to reduce problems associated with sticky and swelling clays. The role of a dispersant, simply put, is to drive things apart from one another. Thinners and dispersants are very small and have a high negative charge, which counteracts the clay particles’ ability to swell. These products can be used to dilute and disperse your drilling fluid. Certain types of emulsifiers can be added to an already hydrated bentonite fluid mix (at the correct dosage) to destroy downhole native clays without affecting the drilling fluid mix.

Fact 3: Detergent/Lubrication Additives

Detergent is a wetting agent (surfactant) formulated to increase the wetting properties of drilling fluids. It assists in keeping the drill bit clean and reduces bit balling. Lubricants are usually a vegetable-based filming-type oil used to reduce rotational torque and drag. They enhance lubricity of water-based fluids without altering the rheology.

Fact 4: Sand Polymers/Additives

Modified natural polymers, also referred to as PAC (polyacrylamide cellulose) polymers, are a great fluid-loss tactic for sand and gravel conditions. Another added benefit of PAC polymers is that they are a great clay inhibitor as well. If pumping pressures are an issue, these polymers are available in low-viscosity versions. Unlike long-chain PHPAs, these polymers are compatible with vibratory reclaiming systems and are a great choice for alternating layers of clay and sand. PAC polymers are available in dry or liquid form.

Fact 5: Natural and Biodegradable Polymers

These are materials derived from natural sources such as plants, animals or microbial fermentation. Many of these polymers are used in food products as thickeners, proteins, gums and starch. Products such as xanthan gum are used in cobble formations where extra suspension is needed to clean the borehole. Guar gum is also an example of a natural product used in the drilling industry in environmentally sensitive areas.

Summing It All Up

My goal was to try and keep this as straightforward and simple as possible. It can be a difficult wire to walk but, if you keep in mind just a few simple ideas listed below, I believe you will see greater success in your operations.

- Fact 1: Use good mix water (treated with soda ash if needed) with a pH of 8.5 to 9.5, and Wyoming sodium bentonite.

- Fact 2: In reactive, sticky, swelling clay soils, use PHPAs or thinners/dispersants.

- Fact 3: Use detergent and lubricant additives to help keep your bit clean and reduce torque and drag in reactive soils.

- Fact 4: In non-reactive soil (sands), use PAC polymers for hole stability. Larger cobble-type situations may require the use of xanthan gum to suspend cobbles and float them out of hole.

- Fact 5: There are natural biodegradable polymers for environmentally sensitive drilling.

Those five facts will help drilling contractors achieve greater success in just about any geology — no Ph.D. required.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!