‘Pilot Drillers’ Tech Makes Drilling Jobs Safer, More Productive

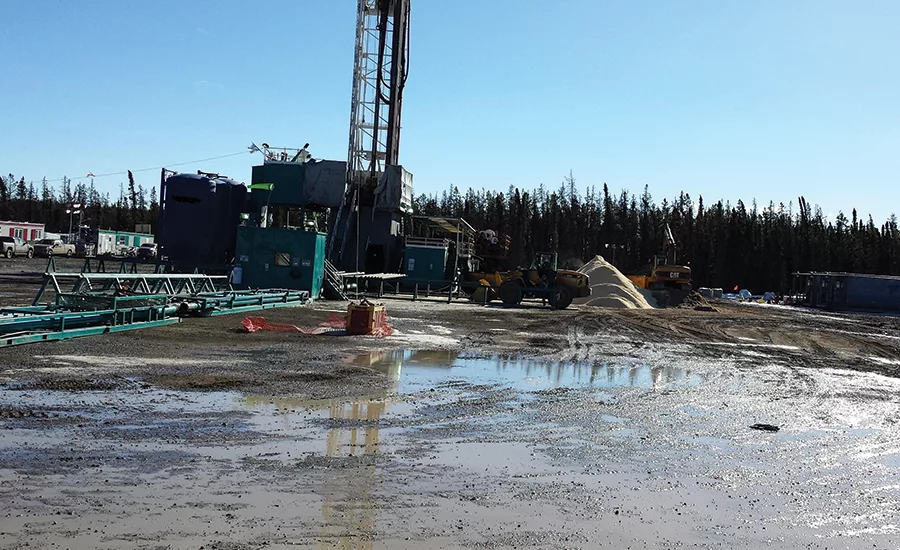

The oil and gas sectors of the drilling industry adopt technology more quickly than others, like water wells. Source: Morguefile.com

It is the end of 2016, and time to reflect on the past business year. Did the year turn out the way you expected? Did you work harder this year than last year, or did you find a smarter way to do business?

The water well industry philosophy is, “if it ain’t broke don’t fix it.” The first portable rotary drill was invented 85 years ago in 1931. This is a fantastic progression to think about. Before the advent of the shovel, civilization progressed only where fresh water was available. The well digger solidified our ability to live anywhere we want. Our grandfathers didn’t dig wells, they spudded them with drive blocks and bailers. Our fathers may have started by spudding, but by the mid-1980s rotary drilling quickly became the new standard.

Regardless of if it was table drive or top drive, the industry’s ability to drill faster, larger and deeper has increased exponentially. Now we are 16 years into the 21st century, where advances in new technology happen every day. The development process has gone from several years to months. At the IADC- Advance Rig Technology Conference in September, National Oilwell Varco stated that the life cycle of creating new technology and introducing it in the field had changed from nine months to nine weeks. Manufacturers in the water well industry make significant advances every year, but by the time we make it an industry standard the technology is more than 10 years old. The only advances we do adopt immediately are driven by safety or new regulations.

What prevents the water well industry from quickly adopting new technology? It’s tough to say, but considering these factors could help us adopt new technology faster:

- Who benefits from the new technology?

- What are your major concerns?

- How do you manage the transition to new technology?

It is time to move from 20th-century technology and become early adopters. Think about the advances of airplanes from 1931 to 2016. In 1931, single-prop mechanical planes were the industry standard. A pilot had to be robust and capable of controlling the plane. The pilot, in effect, worked for the plane. In the 1930s, a plane crashed nearly 12 times for every 100,000 miles flown. In the present day, an aircraft’s control system works for the pilot, relaying all information required to have a safe and successful flight. The present day crash rate is less than 1.07 for every 100,000 miles flown.

What do flying and drilling water wells have in common? Both operations require highly skilled operators to be successful. We should start to think of our drillers as “pilot drillers.” Our “pilot drillers” need an industry that promotes new technology.

The Benefits

New technology has to be a blend of simplicity, ease of use and safety. The innovation has to help our people’s day-to-day routine and increase their ability to get the job done. Automation technology fits this criterion by removing the worker from the danger zone and reducing the effort required to do on-job tasks. The right equipment will shift the concept from a back breaking well digger to a “pilot driller,” who has the energy to play with his kids after a 10-hour day of drilling. Rod handling, breakout systems and downhole drilling systems give the driller and helpers the tools to do more in one day. Choosing the right technology for the purpose is important. What jobs require more labor or time? How can the task speed up? Pilots and the FAA record on-job issues and ask the airline manufacturers to solve problems. Our industry needs the same on-job feedback to create value-added technology that will benefit drilling companies.

The Concerns

Let us start by stating the concerns I often hear for not adopting new technology. These statements chip away at our Industry’s ability to innovate and prevent us from becoming “pilot drillers.”

- New technology will never hold up to the rigors of a water well jobsite.

- Electricity and water don’t mix.

- I can’t fix it on the job if it is too complex.

- If it ain’t broke don’t fix it.

All of the above concerns had validity in the past. However, the industry has changed and so should our way of introducing new technology. Testing new technology on actual jobsites helps manufacturers troubleshoot performance issues and evaluate reliability under the rigors of drilling. We often take equipment to the breaking point to document limitations. We work the machines in extreme heat and sub-zero weather to better understand a full spectrum of performance.

I laugh every time I hear water and electronics do not mix. Major systems on all construction equipment outside of the water well drilling industry operate with electricity. Significant advances have been made to ensure reliability with sensors, proximity switches and electrical controls. Your mini excavator or backhoe most likely utilizes electronic controls. The oil and gas industry uses these controls every day.

New technology is going to come with a level of complexity, but it also comes with new convenience. Yet at the same time, the troubleshooting process has become easier. A technician can start remotely to better understand the issue before arriving at the jobsite. It should be noted that fewer than 5 percent of all equipment failures on oil and gas jobs are from electrical components.

I love the “ain’t broke, don’t fix it” argument. It can be a tough one to rebut. If you don’t know what you are missing, you will never know how much it affects your business’ bottom line. I remember 15 years ago helping my college roommate build a shelf to mount our console television on the wall. The unit must have weighed 100 pounds, but it had a great picture, and all the bars mounted them up high. The complete design process took all day, and it was crude, but our TV was mounted up high. Today the time, money and security deposit lost to build a shelf for that TV would have purchased a new flat screen. Real innovation is technology that we didn’t even know we needed. Think about the transition from horses to car, or cable tool to rotary. Good technology should increase productivity, give you more time and pay for itself.

The Transition or Change

How do you handle the transition or adoption of new technology? The success or failure of new technology depends on your drilling company and the technical manufacturer’s expectations of what the product will do or produce. Proper training is crucial to a safe and productive transition. New processes, controls and automation have a learning curve. New controls will require time to learn, time to “get the feel” of the equipment. The first time I drove a new car with push button start, I remember thinking, “This is weird; no key to turn.” It takes time to learn the nuances and feel of a machine. Often, precision controls at first feel as if they are too touchy; however, what you are feeling is instant movement versus a building pressure that eventually leads to an action. A good transition allows your “driller pilot” time to trust the new technology. Time and training are incredibly important, but there has to be a deadline where you determine if the new technology is becoming productive or preventing productivity. Regardless, the benefits of the new technology must outweigh the transition or learning curve.

The New Normal

There will always be two types of companies: ones that are the early adopters and the ones that wait for it to become the new normal. The new normal 85 years ago was to drill a 1,000-foot well in 10 days. Now we can do it in less than three days. In the upcoming years, we will have innovations that push us past controls and automation. Innovations that will enable us to record and read real-time drill performance data. Technology the oil and gas industry uses every day. This data will allow us to better understand why a job was successful or not successful. The more information we have, the better we can train.

At the Advanced Rig Technology Conference hosted by the IADC presenter David Kaplan, an engineer from NASA, spoke about NASA’s risk assessment involvement with the oil and gas industry. David’s presentation on risk management should be applied to all disciplines of drilling. My favorite quote came from Kaplan during a question and answer forum. He said: “You can’t engineer man out of the technology. It will cost you billions of dollars. However, you can give them the right information at the right time to make the best decision.” The better the technology we adopt, the more time we give our “driller pilot” to make the right choice when the unexpected happens. If oil and gas drillers are striving to work like astronauts, then we can make the transition to thinking like pilots.

Happy New Year, and I hope you have a safe and profitable 2017.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!