Does the Cooper Code Work for Drilling Jobs?

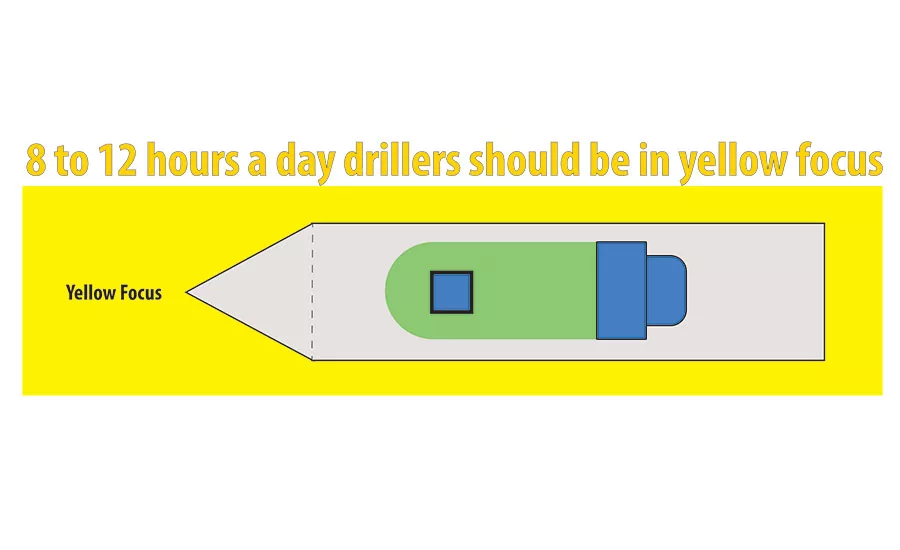

Workers in yellow focus conduct an inventory of their surroundings — the people nearby and any other movements going on around them — and run a cursory “what if” mental visualization for each process undertaken during work hours.

I recently attended a safety training conference where a retired Chicago police officer gave a talk on mental focus and situational awareness. He advocated using the “Cooper code” to reduce incidents and mistakes at the jobsite. I had never heard of the “Cooper code,” so I was intrigued.

The late Col. John Dean “Jeff” Cooper (1920-2006) is a legend in the firearms training community. He earned a political science degree from Stanford before receiving a commission from the United States Marine Corps. He fought in the Pacific in World War II and in Korea before retiring as a lieutenant colonel. Cooper taught high school and college classes before he opened one of the nation’s top firearms training schools for law enforcement and military personnel, as well as civilians. In his work, he developed a system of increasing focus levels, which he color coded white to red.

One of Cooper’s core beliefs was that technical skills (for example, how to load and fire a weapon) had little value without mental preparation. This made sense to me for police and military personnel. But how could the teachings of a firearms instructor become the cornerstone for a program to reduce accidents and mistakes on a drill rig or on the shop floor?

Early on in the talk at this conference, someone raised a hand and asked him how law enforcement training related to worker training. The officer responded, “Let’s look at the similarities between a law enforcement officer’s environment and the environment of the typical work crew.” He went on to list:

- Both get exposed to dangers and/or hazards in a typical workday.

- Both must be constantly aware of their surroundings; any unusual sound of unexpected movement could mean trouble.

- Both require a specialized skill set and training to do the job.

- Both must wear personal protective equipment while working in order to not let the job get the better of them.

As I listened to the rest of the officer’s presentation, I grew convinced that awareness-level training could benefit drill crews and drilling companies. Once areas that may need to be addressed are identified, employers can offer worker training to guarantee a certain level of focus for a given task.

What is the actual Cooper’s code of situational awareness? It breaks down into five “focuses.”

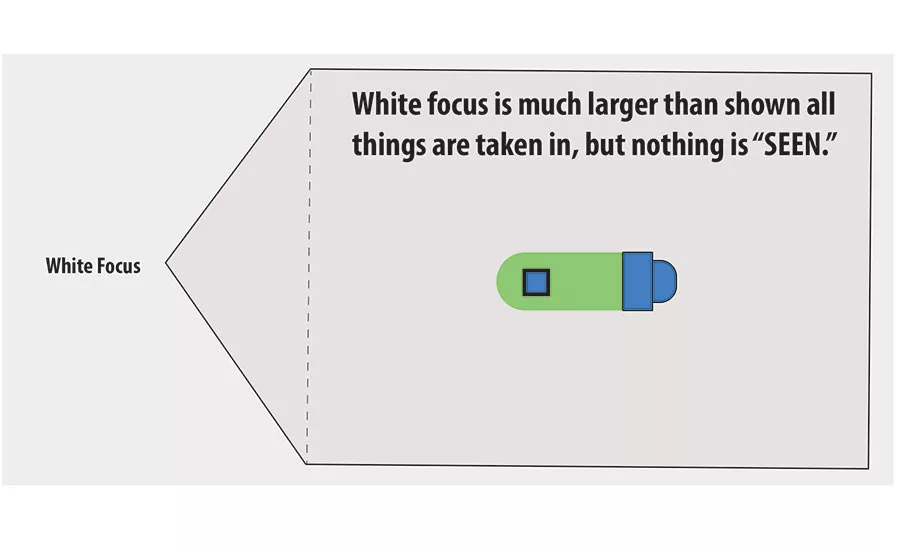

White Focus

In white, you are relaxed and unaware of what is going on around you. Often, we drop our guard at home or in some other environment we believe to be safe. Think of this as a wide-angle lens. We are wide open, but not focusing on any one thing. A common term for this condition is “spaced out.” In a perfect world, no tasks should be done in white focus. Drillers must always be vigilant to make sure they and other crew members do not work in white focus.

Yellow Focus

In yellow, you remain relaxed, but are aware of who and what is around you. You pay attention to the sights and sounds. Yellow focus is useful whether you are at home or moving through society, or at work on the rig floor. Workers in yellow focus conduct an inventory of their surroundings — the people nearby and any other movements going on around them. Workers also run a cursory “what if” mental visualization for each process undertaken during work hours. Most of your day should be in yellow focus.

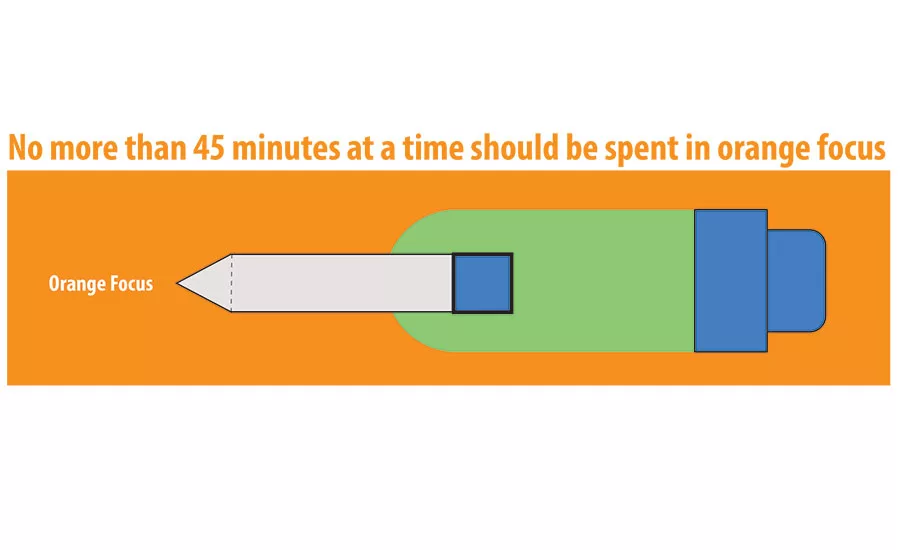

Orange Focus

In orange, you have identified something that may or may not prove to be a hazardous condition. Until you determine the true nature of whatever has piqued your interest, focus narrows to the possible hazard. It should remain so focused until you are satisfied that the hazardous condition has abated or the task requiring increased focus has completed. The problem with a higher level of focus? The average human cannot maintain that high a focus for long periods. There is also a danger that things outside of the focus of the worker may get overlooked due to the increased attention paid to the immediate hazard. For this reason, limit time in orange focus to short bursts.

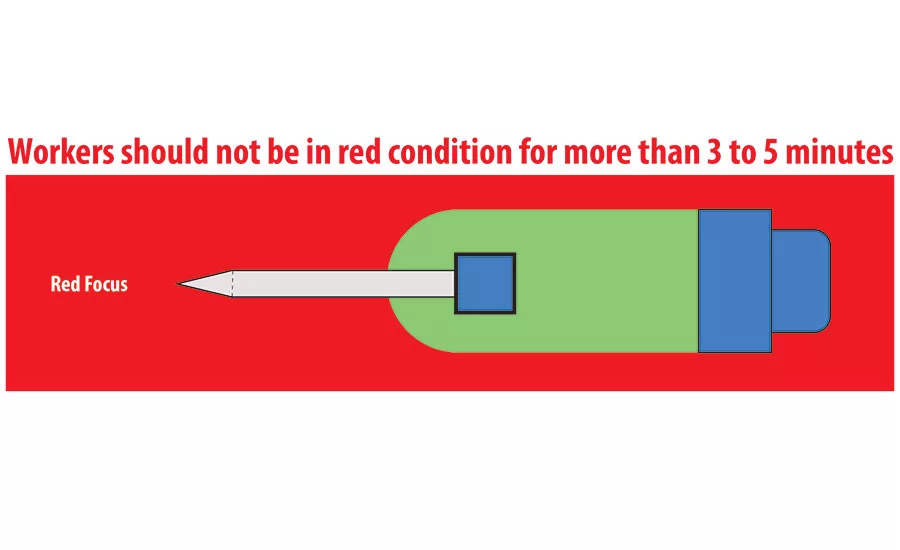

Red Focus

Red is laser focus. This usually means something has gone wrong or, you suspect, is about to go wrong. You do everything necessary to control the situation and ignore all non-pertinent tasks. Situations such as an emergency shutdown take place in red focus. Working in a red focus condition is extremely taxing mentally and physically, and workers should not be in a red condition for more than 3 to 5 minutes over the course of a day. Evaluate any task that requires red focus. Try to find alternative methods to bring the required focus level down to orange or yellow.

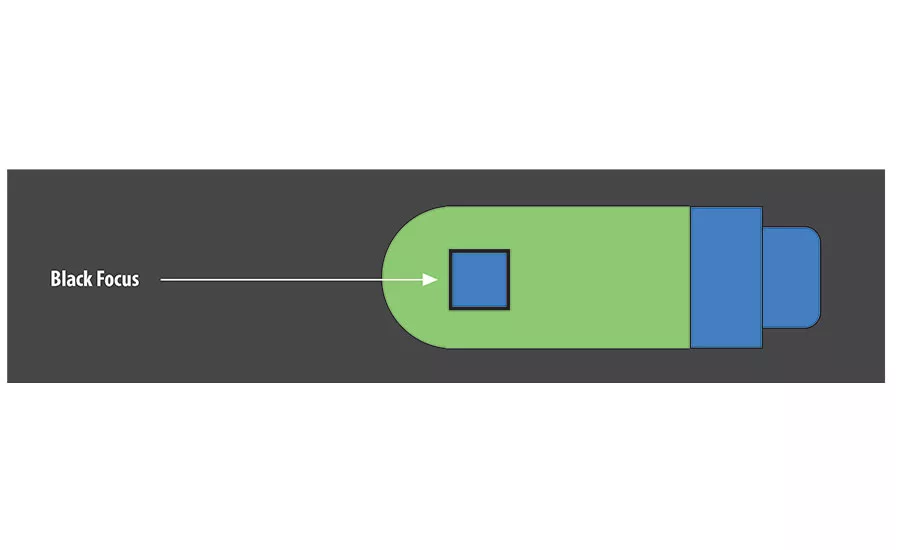

Black Focus

The final level of focus is black. In this level of focus, just as in white, the worker is not in connection with most of their surroundings. Unlike white focus, however, the worker is ultra-keyed-in to one thing to the detriment of himself and everything around him. Black often happens immediately after an event or injury. Some trainers use “black” to describe someone immobilized with panic.

So how do we incorporate this idea into our training? First, evaluate all tasks we ask our drillers to do and determine the level of focus required to do the work safely. Next, have drill crews complete a job safety analysis (JSA) for each task. Ask them what their assessment is of the level of focus required to do the job. If both assessments match and the anticipated level of focus is yellow or orange — and it appears the task can be completed in a short enough time to not stress the drill crew — you’re done.

However, if the levels do not match or the focus level for a given task is above orange, remediate or restructure the task to bring it into a manageable focus level for your crews. Doing this will save workers from injury and save your company money.

I’ll leave you with a quote from Col. Cooper himself: “Safety is something that happens between your ears, not something you hold in your hands.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!