Useful Facts for Fixing Problem Water Wells

Schnieders says evaluating the efficiency of the power plant is very important, especially with larger, deeper set well systems. Source: Water Systems Engineering Inc. photos

Michael Schnieders, PG, PH-GW, has more than 20 years of experience analyzing water well problems and deciding what direction to take in fixing them.

Bailed material from a recently mechanically cleaned well was evaluated by Schnieders’ firm to better understand fouling that was developing in a large-diameter, deep well. It is comprised of calcium carbonate mineral scale, iron oxide and iron from the corrosion within the casing.

What remains of a pump that remained in service long past its projected lifespan. Source: Ned Marks, Terrane Resources

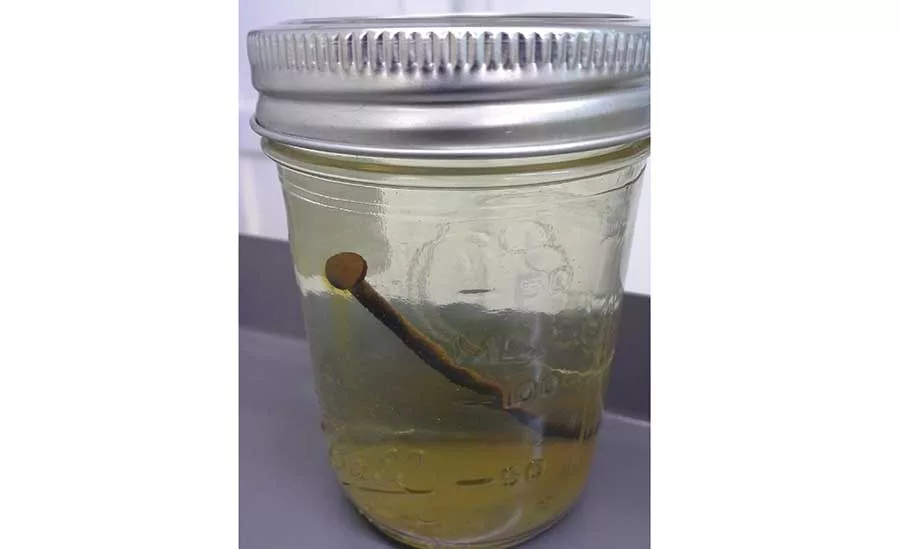

Corrosion of the low carbon steel nail in this nail test, which is evident after four hours, is indicative of corrosive groundwater conditions. Source: Water Systems Engineering Inc.

All too often, Michael Schnieders, PG, PH-GW, sees water well drillers go into projects assuming that a problem well should be diagnosed and treated the same as other problem wells they’ve worked on. That isn’t the case, though. Schnieders points out that every well is different; some jobs call for a sledgehammer and others require a scrub brush. This is why it is important for contractors to take a step back and identify what the problem is, where in the well system it is located and how significant it is. He recently co-authored a book on this topic along with his father, John H. Schnieders, Ph.D., CPC, and colleague Thomas Hanna, PG, of Johnson Screens. “Operational Stage of the Well” is a guide to evaluating forms of water well deterioration and developing corrective actions. Schnieders will cover this at the 2017 South Atlantic Jubilee conference in Myrtle Beach, S.C., as the presenter of the National Ground Water Association’s McEllhiney Lecture. “It’s a big honor, both with the McEllhiney Lecture and Jubilee. Outside Groundwater Week, Jubilee is probably the premier groundwater show for the industry. I’m very excited to attend,” he says.

As president of Water Systems Engineering Inc., in Ottawa, Kan., Schnieders leads a team of microbiologists, chemists, geologists and engineers who provide investigative groundwater consulting. Using an in-house lab, the firm diagnoses water quality, structural and mechanical issues with water wells for contractors, engineering firms, municipalities and government organizations. In a recent interview, National Driller asked Schnieders about some of the key topics in his book and how they relate to effectively fixing problem water wells.

Q. What are the four operational stages of a water well as listed in your book?

A. Stage A: Monitor. Keep the well in regular operation. Stage B: Fouling is present. Plan for treatment in 18 to 24 months. Stage C: Fouling is significant but failure is not imminent. Plan for treatment in six to 10 months. Stage D: You have issues — this is either a loss of quality or the well is not producing. Treatment is needed immediately.

Q. How do you classify the different zones of a water well where changes occur?

A. Zone 1: Upper portion of the well. This is the area that is commonly impacted by flooding, breech of casing, subsidence or other means of surface influence when it occurs. This zone is also where the water level fluctuates, so it is pretty dynamic in that respect. Zone 2: The central or middle part of the well. That area that is most active with regard to flow and key components of the well. When fouling is advanced, this is the area typically impacted with either chemical, biological or mechanical fouling, impacting or influencing flow and/or water quality. Zone 3: The lowest portion of the well. This is the area that is most challenging because, typically, Zone 3 is hydrologically or physically isolated. The reduced flow is reflective of either poor producing zones or isolation. We tend to see a greater occurrence of anaerobic growth and environmental coliforms here. The challenge of Zone 3 is both in identifying the problems and then treating them — both due to the location.

Q. Why do you consider well development the most important part of well construction? Why don’t you think it gets enough attention?

A. A big issue with well development is when it occurs. It’s the tail end of the construction process. Typically, budget and nerves are spent, and even oversight of the jobsite is starting to slack off. People are ready to move on to the next project, whether it’s the driller, the consultant or the municipality. So development gets short changed. That’s one of the major issues that we in the water industry have to express to the other members of our team — the municipality, the accountant and the city manager, as well as the engineer — that it’s a very key time. You’re resetting that producing zone. You’re removing all the disrupted material, removing anything that was introduced during treatment, and then you’re pressing reset on the aquifer around the well. If that’s not properly done, you’re not creating a resource out of that well; you’re creating a problem child.

Maybe that problem manifests itself as reduced efficiencies and the well never performs up to design — either initial design or similar to other wells drilled the exact same way in the same aquifer. Or, that problem manifests itself as a water quality issue and that well typically has higher occurrences of rotten egg odor associated with anaerobic bacteria. Or, it has a higher occurrence of coliform because of blocked and impeded flow down below. Or maybe it’s prone more to corrosive tendencies or scale formation just because that dynamic production zone is not as dynamic as it could be. Sometimes it’s post-mortem; the well is set to be decommissioned. Or, during an internal audit they understand that the well is pumping very inefficient or it’s come up to a complete stop. More often than not, development has played a role. Proper development or the need for redevelopment was overlooked and that’s starting to impact the well or has always impacted the well.

Q. Why is it important to establish a baseline when a new well is installed? What information about the well should that include?

A. Typically, water quality data (chemistry) is collected with the test well to aid in determining targeted zones or as a means of getting the well site approved. Unfortunately, that may not accurately reflect the final well’s water quality and characteristics that govern fouling and maintenance. A baseline water chemistry and microbiology analysis, much like a pump test and an as-built diagram, will give you a benchmark with which to measure the well moving forward and determine what changes are occurring and when maintenance is needed. I’d like to see every new well, whether it’s a backyard well or a large municipal well, have a pump test, efficiency report, final as-built, documentation on the pump and motor assembly, water chemistry and microbiology analysis, and a photo of the well head and surroundings, all compiled and turned over to the owner/operator. All too often this information has to be recreated or mined every time the well is serviced.

Q. How do you determine whether a well needs maintenance/rehab or replacement?

A. It’s a balance between the efficiency of the well — cost to produce water — ability to treat the water, and aesthetics — taste, odor, color — location and economics. Most of the time these problems we see are manifestations of issues occurring downhole that are all too often going unnoticed.

Q. Of the several types of corrosion your book lists, which is the most common?

A. The most common types of corrosion that impacts well systems are the various forms of electrochemical corrosion. In my opinion, the most common occurrences of this are a reflection of the materials chosen and the aquifer water chemistry. A 2016 USGS study found that 50 percent of the states have “moderate to high prevalence of corrosive groundwater.” You can be sure that most of the wells in active use were not designed for corrosive groundwater.

Q. What is the difference between electrochemical corrosion and mechanical corrosion?

A. Electrochemical corrosion is based on a chemical reaction that occurs at the metal surface with a transference of electrons between atoms. Electrochemical corrosion comes in many forms: galvanic, microbial influenced, crevice, pitting, etc. Mechanical corrosion is a more physical process such as with erosion corrosion, the direct physical degradation of the metal due to interaction with solids present in the water, such as in a sand pumping well.

Q. What is the nail test and how useful is it in evaluating water well corrosion?

A. The nail test is a bench study in which you take a nail, comprised of the materials being considered for a well, and place it in a glass jar of the natural formation water and allow it to sit. You observe the changes that occur over several hours and overnight to identify the corrosion potential. For smaller well systems, the nail test is a very economical way to evaluate natural background electrochemical corrosion tendencies. In larger wells, it is an excellent way to test system designs.

Q. What kinds of bacteria are most usually found in water well systems?

A. In our evaluations, we have found that aerobic slime forming bacteria are the most common dominant species found in well systems. Of that category, the Pseudomonas and Bacillus genera are the most prevalent. However, to be fair, they are also some of the most common species found on the planet. Sadly, many in the water industry are misled in thinking that groundwater and wells are sterile. Part of this is a misunderstanding of the subsurface and part of it is the false confidence in the coliform test, a test that just looks for one group of particularly problematic bacteria without assessing the total population present.

Q. What is the difference between mechanical and chemical rehab?

A. Mechanical rehabilitation is a physical act and typically incorporates tools such as a brush, a surge block (swab), jetting tool, or similar means of applying force or agitation. Chemical rehabilitation is the use of specific chemicals to target fouling. As with washing dishes, combined chemical and mechanical is typically the best means of targeting the issues found in well systems.

Q. In the case of oil-contaminated wells or flooded wells, how does one go about removing the unwanted material?

A. It depends on the well, type of oil and extent of influence. In some cases, bailing works. I’ve seen contractors use an oil capture sock to soak up the oil and even small, peristaltic pumps to skim the oil from the surface.

Q. Should disinfection always follow well rehab?

A. Yes. In some cases it is a regulatory requirement before the well is placed back into potable use, but all wells can benefit from this final polishing step.

Q. What does well redevelopment involve and how do drilling fluids play into the need for it?

A. Redevelopment is a form of rehabilitation that specifically targets sediment that has migrated into the borehole or remnant drilling fluids that were not properly developed out when the well was initially constructed. Alluvial wells commonly need redevelopment in a periodic fashion depending on how hard they are pumped and aquifer characteristics. If the well was completed during a drought, fluid loss occurred during construction, or the development process was shortened or interrupted for some reason, redevelopment is often needed.

Q. What is the most common misconception you see with water well troubleshooting?

A. That’s a tough one. I would say that one of the common misconceptions is that there are silver bullets, and every well and every well problem is the same. While we may use similar processes, every well is unique and faces its own individual problems based on the design, construction, operation and historical maintenance, or lack thereof.

Q. What should drilling contractors tell customers about water well upkeep? How should they advise well owners to evaluate performance?

A. A well, whether it’s for a homeowner or a municipality, is no small investment. It should be treated as the valuable resource it is. I would encourage contractors to initiate the conversation of preventative maintenance — which many homeowners are already doing for their HVAC systems or automobile — for the well. An annual pump test and electrical evaluation, well head inspection and a simple water analysis would be very valuable at identifying problems earlier, which can then typically be addressed more efficiently and cheaper than waiting until the little problems become big problems.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!