When and When Not to Embrace New Technology

Founded in 1942, AMS Inc., which manufactures monitoring and sampling equipment for environmental and geotechnical applications, is celebrating its 75th anniversary. Source: AMS Inc. photos

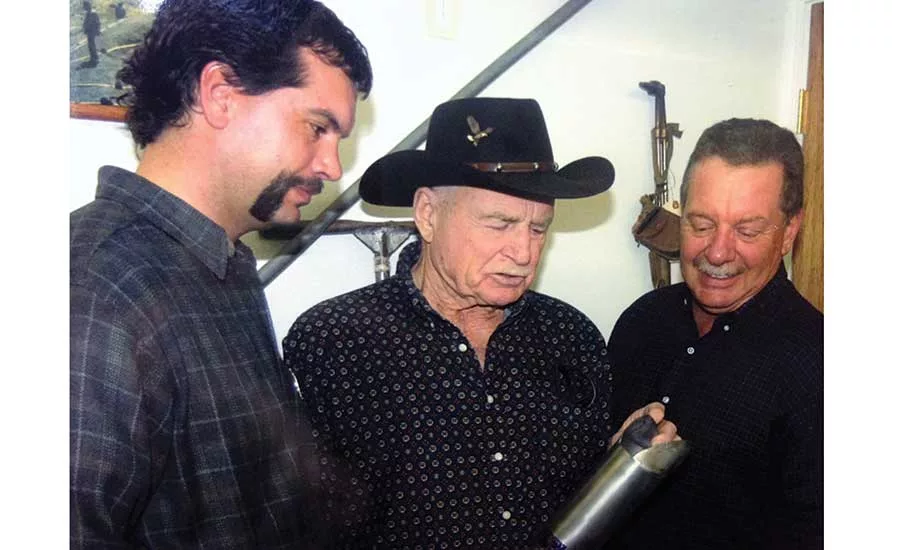

From left: Marc Chipps, grandson of Art Vollweiller, nephew of Rick Vollweiller and president of AMS; Art Vollweiler, the original owner of AMS; and Rick Vollweiler, Art’s son and current owner.

The PowerProbe line of drilling rigs from AMS features direct push drilling technology and hollow-stem auger capabilities. Source: AMS Inc. photos

Rick Vollweiler took the company global in the ’80s and now AMS serves customers worldwide who conduct projects like this one, which took place in Namibia.

In the tiny town of American Falls, Idaho, nestled on the equivalent of a small city block, sits the headquarters of AMS Inc. Rick Vollweiler, owner of the company, says, believe it or not, the vast majority of the residents have no idea what the business does. Little do they know, the environmental and geotechnical sampling and monitoring equipment manufacturer is celebrating 75 years of business — all of them spent in American Falls — and it serves customers across the globe.

“This company’s actually put American Falls, Idaho, on the map worldwide,” Vollweiler says.

Originally named Art’s Machine Shop, the company was founded by his father, Art Vollweiler, back in 1942 as a blacksmith shop. Art’s specialties included manufacturing and repair work for farmers, including the building of hitches. In the early 1950s, he built a hand-operated soil auger that was utilized by the U.S. Soil Conservation Service. It offered an efficient way to bore holes nationwide and, through word of mouth, the soil auger gained popularity.

Rick, who had been helping his dad out since age nine and moved into management in 1980, acquired the company from Art in 1983. He initially changed the name to Art’s Manufacturing Supply and eventually settled on AMS. For the past 30 years, Rick has been joined by his nephew — Art’s grandson — Marc Chipps, who serves as president of the company. Together, they have achieved great success.

“When I bought the company, there were five people here. Now we’ve got 48. I’m proud to say we’ve never had a layoff and the only year that we did not grow [was] in 2001. But every company in the country suffered after 9/11 happened,” Rick says.

Embracing Change

The most important part of sticking around so long has been listening to customers and being responsive to their needs. Rick says his dad always emphasized doing his best, focusing on quality and avoiding shortcuts. Now, Rick tells his employees that if they can’t sign their name to a job when they are finished, it should never leave their station and, certainly, never leave the building.

Ensuring customer satisfaction in a world and industry affected by constant technological advancements has required an open mind. For example, early in his career, in 1981, Rick attended his first environmental conference to market the hand auger to the environmental field, which was an entirely new clientele for AMS at the time, but has become a key market in fostering business growth.

In addition, what Rick learned at other industry events, like those held by the National Ground Water Association, inspired him to design a management system for groundwater sampling and monitoring wells, and a discrete waste level sampler.

Back in the ’90s, spurred by customers’ requests for an automated system, AMS developed the Envirodrill. The machine innovatively combined auger and direct push capabilities. Since then, the company has moved onto a line with more of a direct push function, PowerProbe. “So we’ve been through several different design changes,” Chipps says. “And we’ve just continued to increase capabilities and design changes with different hydraulic capabilities, different engines that are made available this day in age. We’re able to do different things to make a smoother, better running system.”

For example, AMS recently switched to a Tier 4 diesel engine in a lot of its rigs, which Chipps says brings increased efficiency and cleaner burning diesel. They have also switched to different hydraulic hammers to increase depth capabilities. A key concern of the company is the health of the environment, which has led to the implementation of cutting-edge technology, from oils to engines, to keep sites as clean as possible.

Rick says he likes to come out with a new product about every three years, which requires forward thinking. His engineers are helpful in suggesting changes that will increase power without increasing size, while making systems as operator-friendly as possible. “Tooling is a big factor within the sampling industry because everything changes and they need to have different tooling to sample different types of soil and sludges and pond bottoms and lakes and streams.”

A big milestone, which Rick started pursuing in the early ’80s, was taking the company global. Combined with the advent of the PowerProbe, opening up to the international market was significant in taking the company to where it is today, Rick says. AMS has close to 100 distributors worldwide, with the majority based in the U.S. and Canada. The business has also expanded to serve other industries including golf courses, pest control and agriculture.

Holding Onto What Works

Over the years, Chipps says customer demands have largely remained the same; they all want to go deeper and quicker, using the smallest carrier vehicle possible, while cutting costs. Similarly, AMS has remained the same in many ways, and knowing where to hold onto habits has been just as important, if not more, than knowing where to introduce change.

“Most everything that we manufacture today was handed down from grandpa through Rick and we still manufacture using those same techniques, same technology,” Chipps says. “Most of the hand sampling equipment is still pretty similar to how it was from the early days.”

He says AMS has visitors come from all over the world to tour the facility and that they are usually shocked because they envisioned an operation like that of an automobile assembly line; but instead of robots and conveyor belts, they see every piece of the hand augers and soil probes being made by hand.

One benefit of keeping the manufacturing process so similar to its state under Art has been that minimizing automation maximizes flexibility. They are able to do a lot of custom manufacturing. “We will have companies that need a PowerProbe and they’ll say, ‘We want it to do this, this and this.’ So, because everything is handmade and we have such a good engineering team, we go ahead and design these products and we will custom build that probe for their application no matter where they want to take it,” Rick says.

In addition to embracing a handmade manufacturing process, AMS builds as it gets orders. Instead of having a huge inventory of rigs and augers awaiting purchase, Chipps says the team builds as orders come in and ships them out the same day, except for the PowerProbe line, which is usually around 45 days out.

The company’s traditional production system, which keeps more people employed by avoiding automation and circumvents overproduction by waiting for demand, is ultimately about creating quality and it has proven effective. “We have hand augers, for example, that have been in the field for 25 years and they’re still using them,” Rick says.

Speaking of computerization, one thing Rick promises to never implement is an automated phone system. It is important to him that customers are able to voice their needs to a live human whenever they call. A firm believer in customer service, he says taking the time to get to know clientele requires carefully listening, which is only possible with human-to-human interaction.

Responsiveness is a top priority for Rick and Chipps, which is why they urge their sales staff to reply to emails right away and to answer their company smartphones around the clock. “If there’s a problem in the field, you can get a hold of somebody, and if they have to they’ll call me and I’ll find the right technician that they need,” Chipps says.

Another 75 Years

The balancing of change and tradition, and remaining relevant over seven decades have not been easy, but have been rewarding.

“This is my life, my home, my love, with my grandpa and my Uncle Rick...This is what I know, this is what I do and there’s not a bigger honor in the world than to be able to take the reins from my uncle Rick and keep this company going another 75 years.”

–Marc Chipps

Art ran the company for 38 years and Rick is now just a year away from running AMS as long has his dad did. He acknowledges that for a small business to make it five years, let alone 10, not to mention 75, is a huge accomplishment and he doesn’t take it for granted.

“It’s second generation and it’s going to be going into a third generation with Marc,” he says. “So it really is a milestone. I’m really excited that we’re where we’re at.”

Back when Rick bought the business from his father, he asked him a lot of questions and learned a lot from customers. He says Chipps is in the same boat and that he expects the eventual leadership transition to be a smooth one.

Chipps says his uncle has always told him he doesn’t have all the answers, which is why it is important to surround himself with good people. He plans to keep that going.

“This is my life, my home, my love, with my grandpa and my Uncle Rick. I’m 47 and I’ve been here for 30 of those years,” Chipps says. “So this is what I know, this is what I do and there’s not a bigger honor in the world than to be able to take the reins from my uncle Rick and keep this company going another 75 years.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!