When, and Why, to Use Fall Protection on Drilling Jobs

On Jobsites, Falls Are a Common Fatality, Injury

As I sit here on a cool Sunday afternoon waiting for my chosen football team to play their rival, I can’t help thinking how they looked so good at the beginning of the season, and then took a nosedive. This is much like a jobsite: Things can be going so well and then, in an instant, it can all change. In the case of my team, they took a chance on a backup quarterback after a couple of games. He looked good for a little while, but then overnight he played like a backup again and we fell from the top of the division. That precipitous drop inspired my topic for this month’s column: falls.

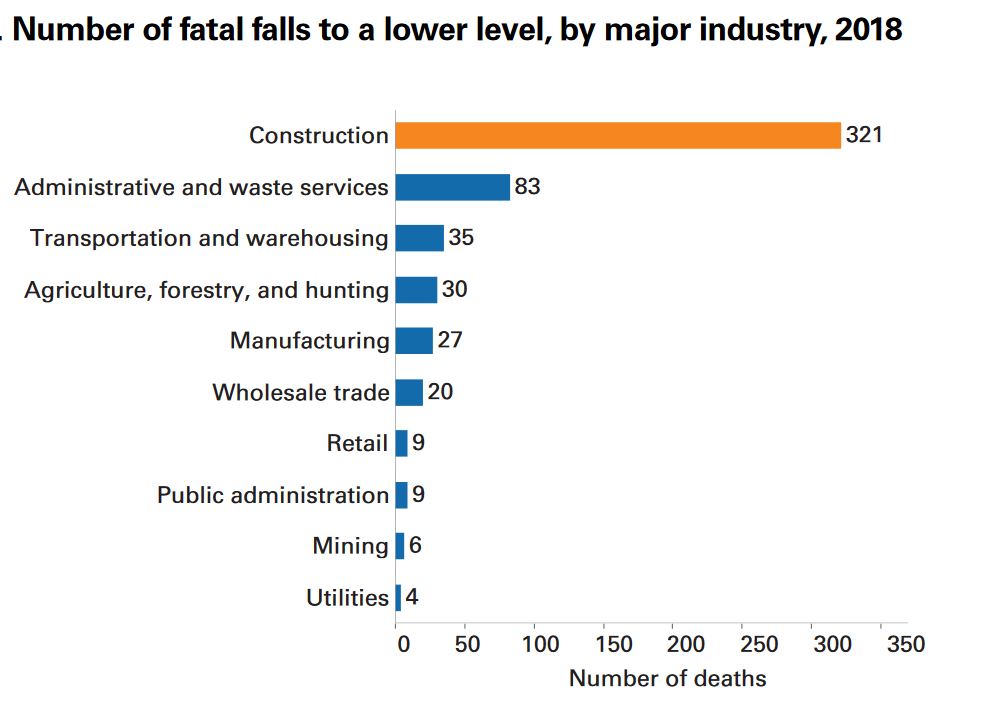

Year after year, falls rank as the number one cause of fatalities and injuries on the jobsite. According to the Occupational Safety and Health Administration (OSHA), in 2018 there were 1,008 construction-related fatalities. Of those, 320 were fatal falls to a lower level (BLS data).

As readers know, I often pull examples from my experiences as a driller. This subject is no different. How many times have you jacked up the drill and wound up, for one reason or another, falling off the step? It has happened to me a few times. When I was young and it happened, I do not remember thinking as I fell, “This is going to hurt.” As I get older, even relatively small falls cause me concern on the way down.

I can’t imagine what possessed me early in my career too free climb a tower to repair a winch that jumped the sheave, or to pin the top section of a mast, without really thinking about it. It had to be done, right? That’s what I thought at the time. With a little reflection, had I given it a bit more thought I could have often made the repair or pinned that mast with less risk to myself and the person employing me. No one ever told me to free climb. On the contrary, most employers would have been more than happy for me to mast-down the rig for repairs or provide the correct fall arrest — if given the right information.

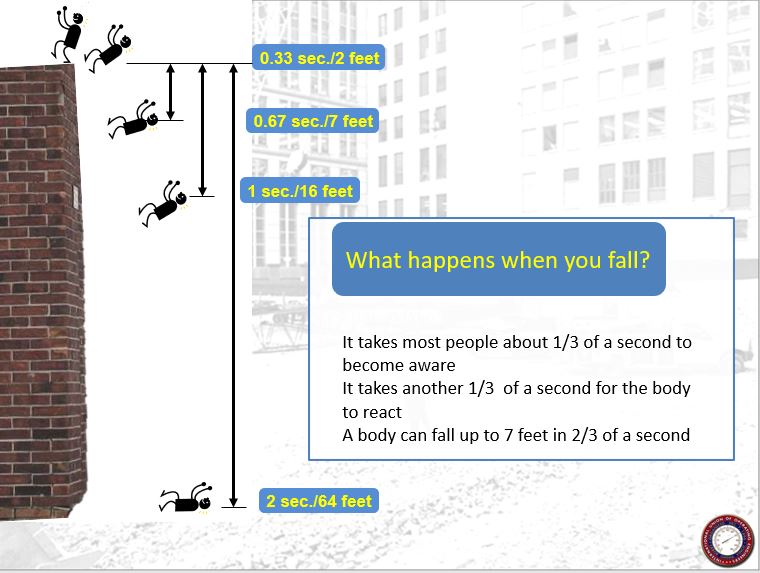

It’s a common fallacy that, if you feel like you’re going to fall you’ll catch yourself. Think of it this way: Have you ever stepped off a step you didn’t know was there? Were you able to keep yourself from stumbling or, worse yet, falling? That’s what a real fall is like. If you’ve ever caught yourself before you fell, what actually happened is you anticipated you were going to fall and, yet, you still almost fell. In fact, it takes most people a third of a second to even grasp they are falling. Another third of a second passes as they try to react, by which time they have fallen 7 feet. By the last third of that first second of a fall, the worker has dropped 16 feet. If the ground doesn’t interrupt, the worker will reach 64 feet by the end of the next second.

So what can we do to prevent falls? The first thing is training on the specific hazards of the job we perform. Next, apply the “hierarchy of controls.” Figure out whether there’s a way to eliminate the job altogether, substitute the job to a safer job, put an engineered fall-protection system on the drill (e.g., a cage or railings), using administrative control (also known as a “rule”) to prevent falls, or issue personal fall-arrest equipment. The most common solution after running through the hierarchy tends to be personal fall-arrest equipment, or “PFAs.” Cages and railings are structural and must be approved by an engineer and done by a certified welder so as not to affect the structural integrity of the drill. Given that, we’ll focus on the use of personal fall-arrest equipment.

Each year between 150 and 200 workers are killed and more than 100,000 workers are injured in falls on construction sites — some years, many more. When we zoom into those figures, we see that, on average, only 10% of those workers used fall protection at the time of the accident. Most often, 75% of the time, they either did not use personal fall-arrest or, worse, had it on but not hooked to an anchor point.

So when does OSHA say we must use fall protection?

| Fall Potential | Allowable Height |

|---|---|

| Fall onto or into dangerous equipment | 0' |

| Break in elevation without a step | 19" |

| First step onto a scaffold system | 2' |

| Work on forms or steel reinforcing | 6' |

| Work on surfaces such as decks, nonresidential roofs, ramps | 6' |

| Scaffold platforms without guardrails | 10' |

| Vertical fixed ladders without cages | 24' |

Also, it is a good rule of thumb that any excavation wider than 24 inches-wide and deeper than 48 inches may require a fall protection system like guardrails or PFAs.

In my next column, I’ll discuss available personal fall-arrest systems, their advantages and disadvantages, and how to use them. For now, let’s just concentrate on not falling off that step. How do we prevent falls from equipment? Do not jump from equipment. Use three-point contact at all times, be sure of your footing, and stay clear of mud and ice.

Until next time stay safe, stay upright and keep turning to the right.

For more Safety 365 columns, visit www.thedriller.com/safety365

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!