Limited Access Drilling: Simple Solutions to Frustrating Problems

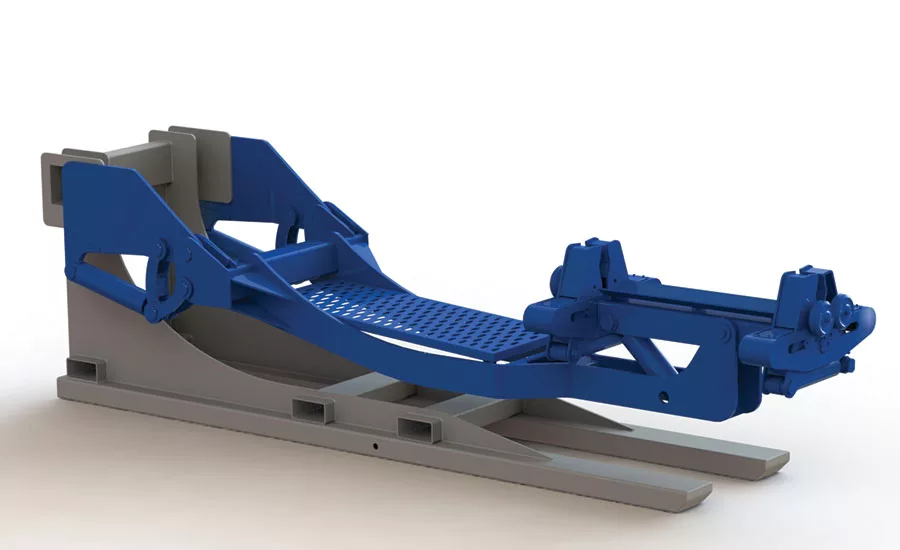

A pipe handler is crucial for the safety of many modern drilling jobs, but it can also get in the way if it’s mounted on a rig that needs to fit into tight spaces. Source: Viking West Engineered Products

It’s a beautiful day for drilling!

That’s the message from thousands of drilling crews each time they head to a new jobsite. Fighting back against a turbulent economy with a shiny new contract in your pocket is a big part of our industry’s new reality. Heck, it’s part of every industry’s new reality. We take the work where we can get it, and then we make damn sure to do the best job possible.

That’s why it’s such a crippling blow when you arrive to the worst possible scenario: Your rig is not going to fit.

Square Peg, Round Hole

Buildings, telephone poles, roads, curbs, existing utilities, trees — it seems like an impressive list of existing structures, but for drillers, surveyors and engineers, these elements might as well come with a gigantic red X painted on them.

For crews that want to take their business to the next level, demonstrating a commitment to safety in conjunction with productivity is the new norm.

The result is a loss of time, investment and energy — not to mention the reputation of your company.

For most of our clients, hands-free pipe handling is a necessary function, a reality of how things are done these days. Hands-free pipe handling isn’t simply encouraged, it’s mandatory for most projects. For crews that want to take their business to the next level, demonstrating a commitment to safety in conjunction with productivity is the new norm.

So what do you do if you’ve got a contract up for bidding, but your pipe handler won’t fit? The new norm is flexibility, both literally and figuratively.

One Drilling Manufacturer’s Solution

Most pipe handlers are mounted directly to drills, which is often a perfectly efficient system. High in the Arctic or in the middle of some prairie or open mine site, a pipe handler that increases the length of the rig is no problem at all. For limited access drilling locations, however, the extra length just doesn’t add up. Or wait, it does add up; that’s the problem!

To solve the need for extra room beside the rig for one of our clients, we mounted our pipe handler on its own separate skid that’s capable of moving around via skid loader as required. The pipe handler is connected to the rig via umbilical hydraulic hoses that allow for quick connect and disconnect. The result is accessibility to the same job, flexibility, maintained site safety and, most importantly, the preservation of an important contract.

A New, Flexible Industry

It’s difficult to talk about the cool things our industry is creating without mentioning the dark cloud of the economy hovering over us. If flexibility is the new reality, it’s because dwindling oil prices have made it a new reality.

Look, your customers are going to expect more for less from now on. The minute you can’t complete a task because your rig simply can’t bend to access the required area, that customer will look elsewhere.

Which is understandable; wouldn’t you do the same?

Our industry is depending on us. Look for new, flexible solutions wherever you can.

Save on costs by maximizing the people and equipment you already have.

And no building, tree or road will get in your way.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!