How Does Fluid-Loss Additive Affect Synthetic Slurry?

Polymers Slurries Have Evolved to Work Better in Cobble

Synthetic polymers have come a long way since the 1980s, particularly when it comes to more severe unconsolidated formations.

Source: CETCO Drilling Products

According to the Caltrans “Foundation Manual,” the “use of the slurry displacement method for constructing drilled shafts began in Texas in the years following World War II.” Mineral (bentonite clay-based) slurry was first used back then for the construction of foundation drilled shafts. It worked to stabilize the soil and prevent cave-ins, while facilitating the removal of material and without the need for casing from top to bottom.

Synthetic (polymer) slurry for the construction of foundation drilled shafts came into play during the 1980s. It offered many advantages over mineral slurry. Unfortunately, uses for synthetic slurry were limited in unconsolidated soil conditions, such as coarse sand, gravel and cobble. Contractors had to either utilize mineral slurry or oscillate casing, which led to higher construction costs.

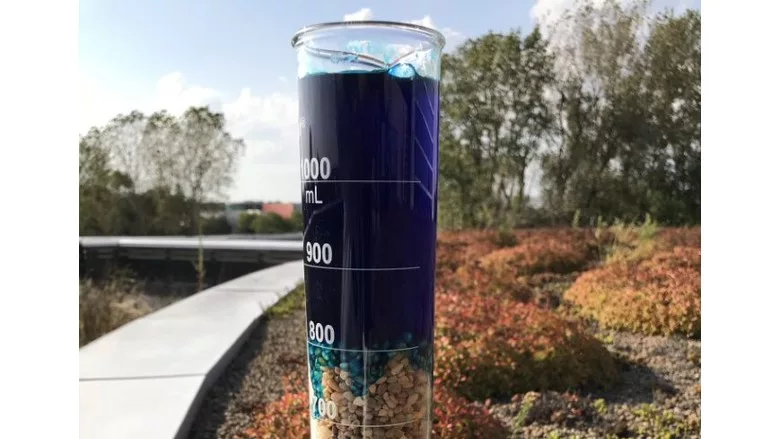

Today, high-tech fluid-loss additives — which I consider a game changer in the world of synthetic slurry for foundation drilled shafts — expand what can be done without the need for mineral slurry or having to case the shaft.

For a drilling fluid or slurry to maintain borehole stability during the drilling process, it must create an almost impermeable barrier/surface between the slurry and the formation. Applying positive hydrostatic pressure to this barrier keeps the hole open. Mineral slurry accomplishes this by creating a filter cake consisting of overlapping bentonite platelets, while synthetic slurry forms a polymer gel membrane. If the filter cake or polymer gel membrane fails to create a seal, or the hydrostatic head pressure applied against either surface is inadequate, the hole will collapse in loose, unconsolidated soil conditions. In the past, bentonite slurry had a distinct advantage in creating this barrier. The microscopic bentonite platelets that formed the filter cake were superior to the synthetic slurry polymer gel membrane in severe coarse, unconsolidated soil conditions.

The game changer for synthetic polymers in these geologies came in the way of new, high-tech fluid-loss additives that enable synthetic slurries to maintain fluid-loss control and borehole stability in some of the most extreme soil conditions. In the past, contractors using synthetic slurry in these conditions would resort to dumping in massive amounts of granular bentonite, bentonite chips or even clay drill spoils from the upper portion of the borehole/shaft. The latest fluid-loss additives may require only one or two pails in a 20,000-gallon tank of slurry — with a better result.

Source: Mike Hagy / PACO

Synthetic slurry offers many benefits over mineral slurry. For example, it may take 500 pounds of 90-yield bentonite to make 1,000 gallons of slurry. You can make 1,000 gallons of a good synthetic slurry using as little as 7.5 pounds of polymer. Mineral slurry suspends drill cuttings and requires the use of costly mechanical solids removal equipment (which, in turn, requires manpower, fuel and lots of space). Synthetic slurry has little to no suspension and works as a flocculent to pull drill solids together into larger clumps that race to the bottom of the shaft where the auger bit picks them up. Synthetic slurry is also a clay inhibitor. It delays the hydration and swelling of native clays, while mineral slurry can become contaminated quickly with reactive clays. Sand content requirements for mineral slurry shafts at the time of the pour (displacement with concrete) are normally 4% or less. For synthetic slurries, that normally falls to 1% or less. Cleaner shafts equal better shafts. A mineral slurry shaft forms a filter cake that can reduce the skin friction/load-bearing capacity of a shaft, while a synthetic slurry membrane is dissolved by the high calcium content and pH of concrete when a shaft is displaced. That translates to better load-bearing capacity. Users can break down synthetic slurries with hyper-chlorination, leaving a non-toxic end product — basically a low-grade fertilizer. According to Caltrans, “processed clay mineral slurries are considered environmentally hazardous and are difficult to dispose of.”

In putting together this article, I found it interesting to get a glimpse of the history of using slurry for the construction of foundation drilled shafts, and reflect on just how far technology has advanced in this industry. One tends to think of synthetic slurry as a newer technology when, in fact, it has been around since the 1980s. When it comes to new technology for foundation drilled shaft slurry, the latest high-tech fluid-loss additives truly changed the game to allow the use of synthetic slurry in a broader range of soil conditions for deeper and larger-diameter shafts.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!