How Can VFDs Boost Business, Save Customers Money?

Constant Pressure Systems Can Prove More Efficient, Reliable

Variable frequency drive solutions have a much smaller footprint than a pressure tank, and can even be wall mounted to save space.

Source: Stephen Brandt

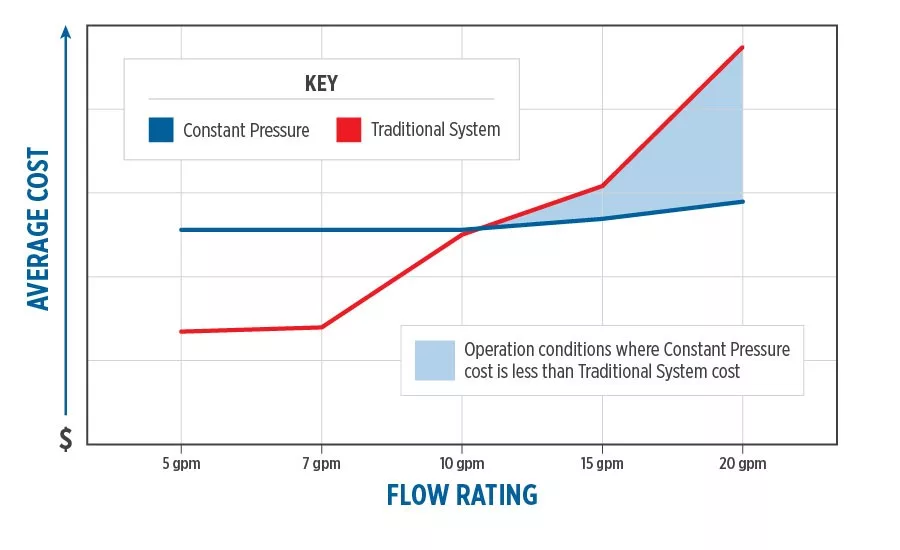

A constant-pressure installation can prove more economical than traditional systems, particularly as flow ratings increase.

Source: Franklin Electric

For many reasons, variable frequency drives represent the next evolution in the increasingly demanding residential water well pump market. Since the invention of the first submersible motor for water well systems, the 4-inch encapsulated motor has proven to be the industry’s most trusted driving force behind residential pumping systems. However, some people working today may not realize just how skeptical folks were back then about running an electric motor underwater.

Today’s innovations, like VFDs, can suffer from the same kind of unfamiliarity. Yet, by enhancing residential water pumping systems with efficient VFD solutions, customers can save money and energy, and add reliability. For starters, a single unit of variable frequency drives can give you the flexibility to cover various size ranges while delivering built-in pump and motor protection. While 2-horsepower jobs and under are the typical requirement at residential settings, today’s existing solutions can help you address jobs for any pumping challenge. A benefit of VFDs with phase conversion is that you can run three-phase motors using residential single-phase power. Even without a three-phase motor installed in the well, you can replace most single-phase three-wire control boxes with this drive, and then upgrade the motor later.

Whatever size motor is present, the drive will only run at the speed necessary to maintain the selected pressure, reducing energy consumption. This feature also helps mitigate damage from cycling issues and most hydraulic shocks.

Why is a VFD ideal for residential use? Most variable frequency drives offer a true soft-start feature, which saves energy, minimizes torque and reduces wear on water system components. Because it matches the pump speed to actual water demand using a pressure sensor (or optional pressure transducer), there is no need for a traditional pressure switch. That means, whatever size motor is present, the drive will only run at the speed necessary to maintain the selected pressure, reducing energy consumption. This feature also helps mitigate damage from cycling issues and most hydraulic shocks.

For the services we deliver, Franklin Electric’s SubDrive Utility (UT3P) has made a difference. We find it a compact, easy-to-install solution that can boost your pump business in ways that you may not yet realize — particularly for three-wire/three-phase residential applications. If you’re new to installing drives for water systems, you might find peace of mind in a more simple introduction to the full spectrum of possibilities available. For jobs that demand more customization, we like knowing VFDS can deliver full-featured solutions with mobile connectivity for setup, monitoring and troubleshooting.

Cut Costs on Copper Wire, Pressure Tanks

Have you seen the price of wire and tanks lately? Keep your bids competitive while giving customers the features and benefits offered with a VFD. In combination with a properly sized pump, adopting this technology provides a cost-effective solution for driving a three-phase motor, while also reducing spending on copper wiring and pressure tanks.

For example, by installing a variable frequency drive with built-in short-circuit and over-current protection, you can downsize the wire to the three-phase motor to #14 for nearly all pump sizes without changing the 20A breaker. For a two-wire or three-wire, single-phase motor (without overload protection) on a 20A breaker, the legendary AIM Manual (Application, Installation, Maintenance) limits a 1-horsepower motor to 400 feet of minimum #12 wire and a 1.5-horsepower motor to 310 feet of #12. Using a three-phase motor powered by this solution, we are allowed 560 feet of smaller #14 wire for a 1-horsepower motor, and 420 feet of #14 for a 1.5-horsepower motor! Look at your deepest pump settings and do the math: Three-phase motors offer an alternative to keep deep pump sets from reaching deeper into your pockets.

Then, consider pressure tanks. They have a large footprint and often cost more than the pump itself. When tanks fail, they may damage the pump and controls. And, how many tanks are you able to keep on the truck?

Since VFDs do not require large tanks, customers are positioned to save money on future tank replacements. Should the tank fail, the pump is protected. A single-phase, 20-gpm pump typically requires a 60- or 80-gallon bladder tank. At our installations, while pairing a variable frequency drive and a pumping system powered with a quality submersible three-phase motor, all that is needed is a 4- or 8-gallon tank. (Of course, always refer to the owner’s manual.) Seven 4-gallon tanks cost less than one 60-gallon tank, and they easily fit into a service truck compartment. A lightweight, 4-gallon tank can be replaced in as little as 10 minutes.

Listen to Your Customers

Homeowners put a premium on space. With a compact solution, you can mount the VFD and tank on the wall and free up valuable floor space for water treatment or other uses. Three-phase motors are nearly silent and greatly reduce the noise associated with traditional pumping systems.

Families have higher expectations for their home appliances than ever before, and a VFD paired with a three-phase motor helps you deliver better performance. The drive eliminates the traditional control box and pressure switch, which eliminates out-of-water service calls for these components.

Deliver Constant Pressure, not Problems

Once available only to commercial customers, submersible three-phase motors can now be installed at virtually any residential job by recommending a compatible variable frequency drive. Keeping up with the latest technology, we have made the variable frequency drives matched with a superior three-phase submersible motor, our standard setup for every new well that we drill. We also consider full-featured solutions with mobile connectivity as an optional upgrade for customers who benefit from added features. Our customers feel that we provide a modern, professional water well pumping system that is distinctly better than others in the market. These innovative technologies are designed to help us deliver constant water pressure, not constant water problems.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!