Hydrostatic Pressure: Both a Friend and Foe for Drillers

Keep Your Fluids and Slurries Clean, Above Water Table

In horizontal applications, keep the level of drilling fluid above the borehole and water table.

Source: CETCO Drilling Products

In drilled shaft applications, surface casing can help drillers maintain positive hydrostatic pressure.

Source: CETCO Drilling Products

Most drillers have, at one time or another, attended a mud school and have heard the term “hydrostatic pressure.” Hydrostatic pressure plays a critical, yet often overlooked and misunderstood, role in drilling applications like mud rotary and foundation drilled shafts. I want to offer readers some insight into the concept of hydrostatic pressure and illustrate how it relates to keeping a hole open.

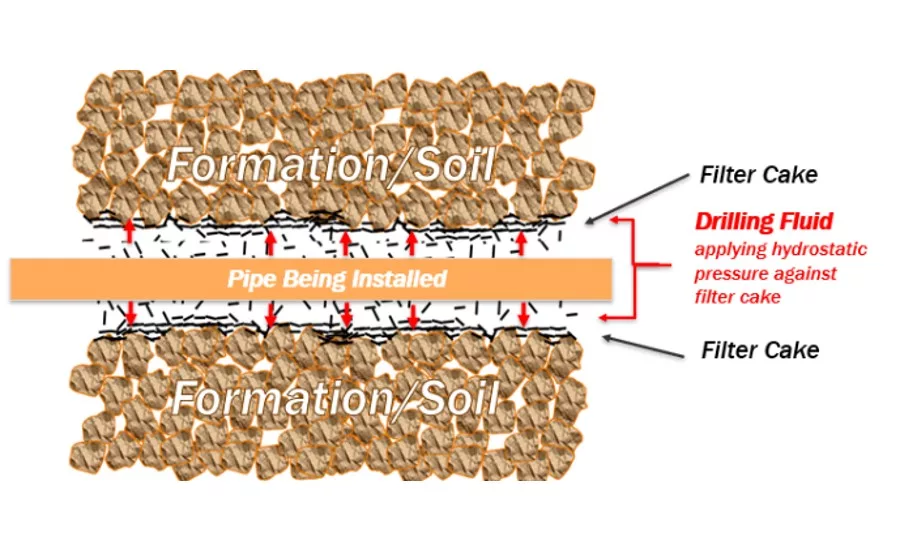

Whether vertical or horizontal, mud rotary or drilled shaft, the key to a successful bore lies in keeping the hole open. For a drilling fluid or drilled shaft slurry to maintain borehole integrity/keep the hole open, a driller must create conditions where positive hydrostatic pressure applies evenly against an almost impermeable filter cake or polymer gel membrane on the walls of the borehole. Hydrostatic pressure is the pressure exerted by a fluid at equilibrium at a given point within the fluid due to the force of gravity. Hydrostatic pressure increases in proportion to the depth measured from the surface because of the increasing weight of the fluid exerting force from above.

In horizontal and vertical drilling applications, calculate basic hydrostatic pressure as follows:

mud weight x 0.052 x depth = psi

For example, in a horizontal application the equation might look like this:

8.5 lbs./gallon x 0.052 x 30 feet = 13.26 psi

And for a vertical application the equation might look like this:

8.5 lbs./gallon x 0.052 x 200 feet = 88.4 psi

At the water table, soil becomes saturated, making it increasingly difficult to maintain borehole stability. You create positive hydrostatic pressure in a borehole by maintaining a fluid level above the water table. In vertical rotary mud applications, it’s a clear process. If one has a good filter cake (low fluid loss), keeping the hole full of drilling fluid throughout the drilling process and maintaining good drilling fluid properties (low fluid loss and low drill solids) will help ensure success.

At the water table, soil becomes saturated, making it increasingly difficult to maintain borehole stability. You create positive hydrostatic pressure in a borehole by maintaining a fluid level above the water table.

In horizontal directional drilling applications, things get a little more complicated. As long as you keep the level of drilling fluid above the borehole and water table, maintain proper drilling fluid properties and sustain positive hydrostatic pressure, you have a much better chance for success. If you drill from an entry pit to an exit pit, make sure the level of drilling fluid stays above the borehole and water table (as depicted in the picture). Make sure the Hydrovac operator does not suck the pit dry. If that happens, the top of the borehole will collapse and coarse soils like sand can collapse throughout the bore. This leads to lockup and potential loss of drill rods and tooling.

For foundation drilled shafts, experts recommend maintaining a minimum of 6 feet of hydrostatic head pressure above the water table, especially when using synthetic slurry. If the water table is at or within 6 feet from the surface, use a surface casing to maintain adequate hydrostatic head pressure throughout the drilling process.

Hydrostatic pressure doesn’t have to be great, but it does need to be positive. For example, a synthetic foundation drilled shaft slurry will weigh around 8.45 pounds per gallon. Six feet of hydrostatic head above the water table (8.45 lbs./gallon x 0.052 x 6) results in 2.6364 psi of positive hydrostatic head pressure applied against the filter cake or polymer gel membrane throughout the shaft.

Maintaining borehole stability requires good drilling fluid properties. Match the drilling fluid or slurry to the soil conditions. This includes adjusting drilling fluids or slurry to the required viscosity and adding the proper additives to reinforce the filter cake and suspension (for rotary mud drilling) in unconsolidated formations, and to control clays and shales in swelling or sticky formations. Pre-treating mix water with soda ash also helps ensure that both bentonite drilling fluids and synthetic slurries perform as needed. In rotary mud applications, flow is an extremely important factor.

In vertical applications, it is critical to have adequate annular ascending velocity to get cuttings out of the hole. In HDD, adequate flow is paramount to avoiding outrunning the drilling fluid, which can lead to thick, heavy returns that result in frackouts, stuck drill stem and damaged roadways. Look again at the equation for hydrostatic head pressure. If you do the math, you see that increasing fluid density or weight increases hydrostatic head pressure in a borehole. This makes maintaining proper flow or proper volume of fluid extremely important. If a drilling fluid in an HDD application, as an extreme example, jumps to 19 lbs./gallon, hydrostatic pressures can jump to 29.64 psi. In vertical drilling applications, that 19-pound fluid pushes the hydrostatic pressures up to 197.6 psi. This could be enough to cause inadvertent returns on a horizontal borehole (thicker and heavier fluid causes higher annular pressures) or lost circulation on a vertical hole. Avoid these situations by ensuring you pump enough fluid and that the fluid is clean (that is, has low drill solids).

In conclusion, good drilling fluid or slurry practices can make hydrostatic pressure a driller’s friend. Maintain proper drilling fluid or slurry properties, ensure proper flow or volume, and maintain adequate hydrostatic head. Hydrostatic pressure can also be a foe, with bad fluid loss to the formation from an improper drilling fluid or slurry mix, or high density/solids fluids increasing hydrostatic pressure beyond the formation’s capacity.

I hope everyone is staying safe out there. The light at the end of the tunnel has appeared and we’ll see each other in the field soon.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!