Fall Protection 101 for Drilling Jobs

What Are the Requirements, Features of Common PFA Devices?

Whatever personal fall-arrest equipment a company chooses for their employees, it’s critical that employees get thoroughly trained by a competent trainer.

Last month, we discussed the physics of a fall and the best practices to keep a simple fall from happening. This month, I would like to discuss how to prevent falling from height and personal fall arrest systems (PFAs). What are the advantages and disadvantages of using different types of PFAs?

Drilling operations sometimes require work at a height over the Occupational Safety and Health Administration (OSHA) fall protection distance of 6 feet above a surface. Working high above the ground or floor of a drill presents one of the greatest hazards for any worker. According to the Bureau of Labor Statistics, 4,405 fatal falls occurred in U.S. workplaces (all types of work) in 2013. Many of these falls were preventable with the use of fall prevention best practices, including fall restraint or personal fall-arrest systems. Think of how these falls affect the family and friends of those 4,405 people. How much heartache could proper use of personal fall-arrest systems save? Now, think of the effect on your family if you were to experience a fall.

PFAs for Drillers, Other Types of Workers

What are the components of personal fall-arrest systems? The first, and most important, component is proper training in the use of whatever type of PFA system is provided. Beyond that, these systems must include a full-body harness. (Body belts and single-acting snap hooks have been prohibited for use in PFAs since 1998.) Anchorage points must be capable of supporting 5,000 pounds per worker attached to the anchor point. A connection apparatus could include a lanyard, deceleration device, retractable lifeline or a suitable combination of these. OSHA requires use of personal fall-arrest systems to meet the following requirements:

- The employer shall ensure training in the PFA system or systems for each employee by a competent person.

- PFAs must be inspected prior to each use.

- There should be no free fall more than 6 feet.

- PFAs may only be subjected to one in-service loading (or “fall,” in layman’s terms). After a fall, the involved PFAs must be inspected and certified for safe use again prior to being put back into service. As with training, this inspection and certification must be done by a competent person.

- There must be prompt rescue after a fall.

Now, I know what happens much of the time: an employer buys the cheapest personal fall-arrest equipment they can find that complies with OSHA regulations, and provides minimal training. Don't believe me? Walk around any big box store and look at the people using the order pickers. They all have personal fall-arrest equipment, but the body harness often does not properly fit. Many times, they use a 6-foot lanyard for a fall hazard below 18 feet — sometimes as low as 15 feet.

Many of these companies — if not all — have deeper pockets then most of our drilling companies. So why the discrepancies? The answer lies in why a company implements PFAs. Do they provide personal fall-arrest systems to comply with regulations, or to safeguard their workers? Often, the answer is a little bit of both. No one wants anyone to get hurt at their business. However, the notion that safety costs money is a big motivator, so they look for ways to be safe at as cheap a cost as possible.

PFA Features Explained

It may confuse people to hear me criticize anyone — like these big box stores and their workers — who actually uses safety gear. If I use a PFA with a 6-foot lanyard attached to the back ring of my full-body harness that I have inspected, properly fitted and attached to an anchorage that will support 5,000 pounds, I have done everything I need to be compliant (as long as my employer has the record of my training by a competent person). Right? Let me explain.

Consider a typical fall scenario involving a 6-foot-tall, 220-pound worker like me. If this ill-fitting system were to save me in a fall, and I freefall the maximum allowable distance according to OSHA regulations, upon stopping, my body would be subject to force of about 2,760 pounds. I would most likely sustain injuries. In fact, the average hospital stay after being saved by a PFA is two weeks. Limiting that force is key to limiting injuries.

Now, OSHA limits the force PFAs can place on a body to 1,800 pounds anyway, so we must do something to reduce that force if we fall. That starts with proper fit for the harness (refer to training and manufacturer recommendations). Then, we implement some type of deceleration device. The most common type of deceleration device is a shock pack or shock absorber. This simple length of webbing folds over itself and is sewn at each fold so that it reduces risk of injury during fall arrest by dissipating energy and limiting deceleration forces that a fall-arrest system imposes on the body. Shock absorbers activate when 450 to 550 pounds of force pull against the stitching. Even though this type of device is very simple, it is also very effective. Shock absorbers have been shown to reduce the force of arresting the fall of the same 220-pound man down to 830 pounds. This comes with a drawback, however. If I add a shock pack to my 6-foot lanyard, the deceleration device adds 3 feet or more to my total fall distance.

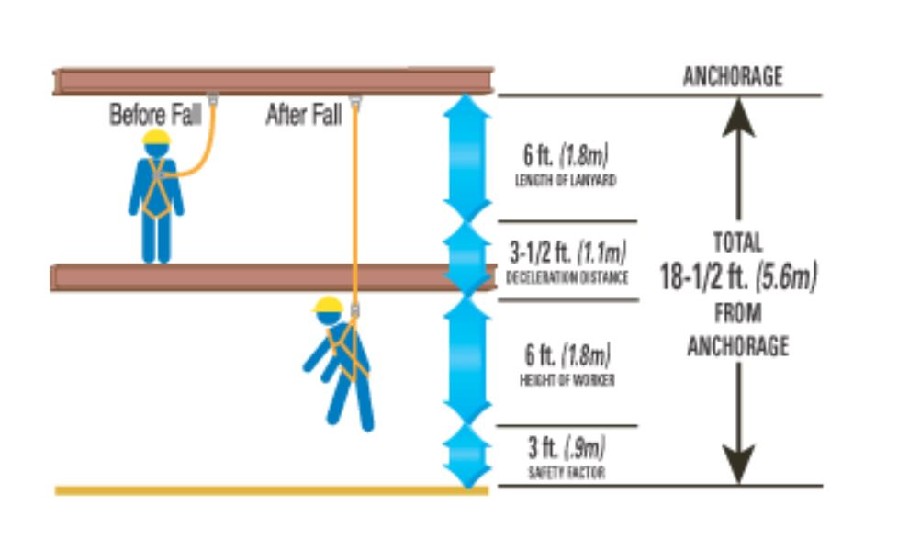

I must use fall arrest if my anchorage sits higher than 15 feet above the ground. If I have a 6-foot lanyard and a shock pack and I fall, I will freefall 6 feet before the shock pack deploys for another 3.5 feet. Then, the back D ring of my body harness winds up at the back of my head, adding another 6 feet. Then, I add 18 inches for something called “body elongation.” My total fall distance becomes 17 feet. If I were anchored at 15 feet, I would hit the ground. Prudence says I should be over 18.5 feet before I use this type of fall arrest system.

A personal fall limiter or a retractable lifeline may provide a better choice for anchor situations under 18.5 feet. Retractable lifelines replace both the lanyard and shock pack, limiting freefall distance to 2 feet or less. They also allow a greater range of motion. The system allows cable to be let out unless a fall is detected. A personal fall limiter allows freefall up to 42 inches with built-in deceleration. Both reduce the forces to half or less as compared to a shock pack, while also reducing fall distance.

Safeguarding those performing drill jobs from falls is a critical, but broad, topic. I’ll continue this series for a couple more articles. Until next time, stay safe, stay upright and keep turning to the right.

For more Safety 365 columns, visit www.thedriller.com/safety365

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!