On Tough Drilling Jobs, Finding Solutions is a Quiz Show

As a contestant on Who Wants to be a Driller, one of your options is to consult the audience — the other members of the drilling crew.

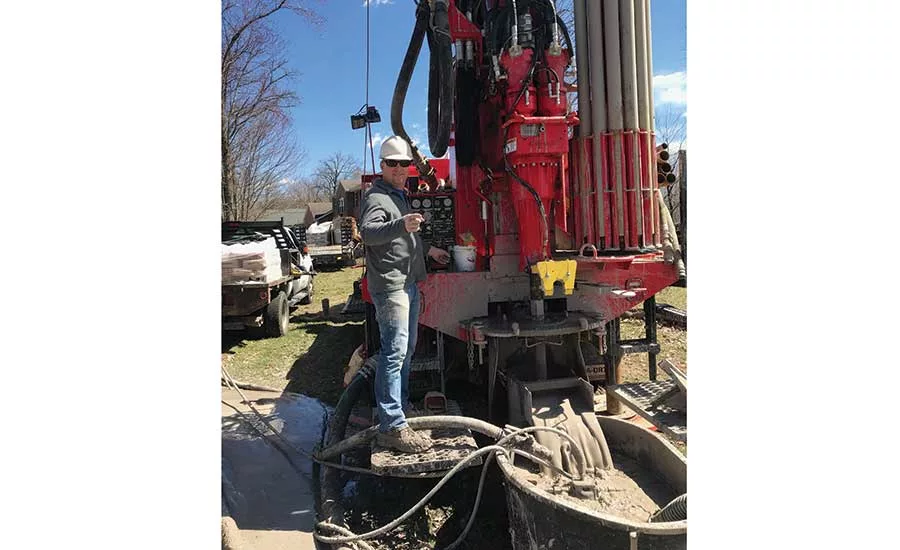

Source: Brock Yordy photos

The drilling game isn’t about winning or losing. It’s about providing quality water to customers.

Does your plan get to well completion with clear steps, yet remain flexible enough for unexpected challenges? Sometimes it takes phoning a friend to get to the best results when a well goes sideways.

Source: Brock Yordy photos

Does your plan get to well completion with clear steps, yet remain flexible enough for unexpected challenges? Sometimes it takes phoning a friend to get to the best results when a well goes sideways.

Source: Brock Yordy photos

Drilling success requires proper planning followed by thorough execution of that plan. However, what happens when the plan doesn’t work? A good drilling plan requires the ability to make changes when new information surfaces or when the plan starts to fail. When unforeseen problems occur on a project, I imagine myself as a contestant on “Who Wants to be a Millionaire.” When the drill plan isn’t working, I have four options just like the game show.

- Answer it alone. Utilize past project experience to create a plan to answer easy questions alone.

- Ask the audience. I can get the drill team together and utilize all of our experience and perspective to make a decision.

- 50:50. Use the trial and error method to see if the outcome changes.

- Phone a friend. I can call a friend, mentor, industry expert or all-in-one, “My Dad.”

Who Wants to be a Driller and the Millionaire game show have many similarities, starting with an easy million dollars’ worth of drilling equipment on site making the stakes very high. You have a short amount of time to answer questions before failure can occur downhole. Finally, just like the game show, the rules do not say “you have to go at it alone.” The best solutions come from a team effort.

Last month, my team and I played a challenging game of “Who Wants to be a Driller.” The location was in an older subdivision that required a contaminant-free water well before a building permit could be released. The local health department authorized the well permit with a minimum depth restriction of 130 feet. The restriction was created because the area in question is known to have several issues, including nitrates, arsenic and new human-made contributions like PFAS and chlorides.

I created my drill plan based on all the information available, including well logs adjacent to the project location. The local records verified that a production zone could be screened between 133 feet and 148 feet. I believed I had my answer key to the game. As we started to drill, I began my field log. In the first four rods, I noted that static water level was at 8 feet, and in that first 80 feet we had passed several high-capacity production zones. At the sixth rod, the team started looking for active signs of the production zone. We sampled every foot between 125 feet and 140 feet, and only encountered two embedded sand layers, each less than one-foot thick, at 128 feet and 135 feet. At 140 feet we encountered shale, and continued in shale to 200 feet. We failed to find the previously logged production zone.

In the hot seat, I choose the 50:50 option.

There I was sitting in the Who Wants to be a Driller chair with the question in front of me. “Brock, how do you create a water well in a production zone laminated with sand, clay and shale?” I concluded that the zone must be very faint, and we mudded it off. We were operating with a 300-gallon mud pan and a 650-gallon solids control unit. I checked the drilling fluid property log to better understand the impact the fluids had at 125 feet. The mud weight was 8.9 pounds per gallon, sand content .5 percent, funnel viscosity 38 seconds per quart. The fluid properties were not perfect, but also far from being able to seal off our target zone.

I decided to choose the 50:50 option, and move forward and try again. The team abandoned the first hole with sodium bentonite chips and moved the rig forward 6 feet to start the second hole.

Phone a Friend

We started the second day optimistic, knowing that we would make a well at target depth if we methodically studied every inch of formation from 130 feet to shale. To increase my odds of success, I phoned my colleague, Tom Howe, to independently log the hole alongside me. Tom works for Western Michigan University and is co-director of Western’s Hydrogeology Field Course. Tom and I teach drilling week of the field course together, and he is a trusted colleague and friend. Tom’s insight was invaluable.

“The rules [of Who Wants to Be a Driller] do not say ‘you have to go at it alone.’ The best solutions come from a team effort.”

He started his log by reaffirming my instincts about the best production zone being between 70 and 80 feet. He then noted a viable production zone from 110 to 114 feet that had a small confining layer above it that I missed on the first hole. However, our goal was to create a well within the depth restrictions, so we continued to target depth. We encountered the same two small sand seams and this time we screened that zone. Sadly, the zones pumped less than five gallons a minute, and in this area of West Michigan, that is considered a poor well. We had made a well within the permit restriction, but the team and I were unhappy with the results, so we moved to the other side of the lot in hopes that the formation would give us a larger production zone at 128 feet.

Asking Judges for an Alternative Ruling

The rules are different in Who Wants to be a Driller, and I am free to use my game show options on each hole. I started by phoning another friend and my first mentor, Chuck Yordy. My father is a surgeon when it comes to finding and screening tiny production zones.

Next, I broke the fourth wall and asked the judges for some wiggle room. I contacted the sanitarian who issued the well permit to discuss his prior experience in the subdivision and what I had learned so far. He was not surprised to hear from me and explained that many of the homes in the development had asked for a variance, and that if we could define a solid confining layer and the water quality test passed, he would issue the building permit.

We discussed the options with the builder and homeowners, and they wanted to try one more time for a well at 130 feet, and if it didn’t pump enough we would create a well at a shallower depth.

We moved the rig 1,000 feet away from the first two holes and again drilled to the top of the shale. My father showed the drill crew several small formations that could be screened, yet none of them were at target depth. The local logs even stumped him. As the drill team tripped out of the hole, I compared log notes with my father, the surgeon. He noted a solid confining layer for 6 feet, and below it was a clean production zone and father like son, I had noted the same zones as him.

Ask the Audience

Again, there I was sitting in the gameshow chair with the question looming over my head. Do we leave the family with a low-producing well, or try the high-capacity zone that could be contaminated? I asked my audience — the drill team and my father. As a team, we decided to screen the high-capacity zone and take water samples. A week later the sample results came in, and the water quality and chemistry were safe and well below all permissible limits. We made our final answer, and it was correct!

Final Review and Answer

After every project, I take time to do an after-action review. I simply ask, “What was supposed to happen, and what really occurred?” We were supposed to create a well in one or two days. What really occurred was a couple of dry holes and a lost screened package. At first glance, that statement looks like an epic fail; however, in five days of drilling the drill team logged and defined the geology for the area. We coordinated with the local university and health department to discuss all options. Finally, we found a clean, productive water source that could change the depth restrictions for that subdivision.

To learn more about the water well business, click here!

When playing Who Wants to be a Driller, it is not about winning and losing. It is about providing a high-quality water source for your customer. Winning for the driller and team is utilizing all the tools available, starting with a good drill plan with all the right information to answer many easy questions alone. Next is asking the audience, with a full step-by-step discussion with the drill crew of what occurred to understand what was missed. After we have that information, we can attempt it again — like utilizing the 50:50 to eliminate past options that didn’t work. My favorite, and the best tool we have, is asking for help from our experienced community. I phone friends often, and I take phone calls from friends daily. I love using the Bluetooth in my truck to call my expert friends when I’m in trouble. Just this week, I have talked to my downhole hammer expert Mike Epley, the cathodic guru Rex Penry, supply-me-anything Rob Bruce and the rigging-safety-geotechnical master Dave Bowers. I am thankful for all my experts and mentors, contacts only a phone call away. If you have an industry question, don’t hesitate to ask, I am always looking for good questions for “Ask Brock.”

Henry Ford said it best: “Failure is simply the opportunity to begin again, this time more intelligently.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!