Tips for Meeting Emissions Regulations on Drilling Jobs

Sooner or later, each individual or organization active in the drilling world and using engines will need to deal with the realities of emissions regulations put in place by the Environmental Protection Agency (EPA) and, with implementation of Tier-4 Final in the diesel world, even those not currently looking to buy new equipment may be affected.

No need to be suspicious that the EPA is out to simply make things tougher. In fact, what has been happening with engine development since the EPA got involved might be worth “singing” about.

Solid Technical Groundwork

An early discovery regarding lowering emissions was that exhaust gas recirculation (EGR), where an amount of benign exhaust gas is introduced into the intake air, effectively and economically reduces combustion temperatures and minimizes the production of unwanted NOx.

Another was that fitting a turbocharger would not only promote better combustion, but also allow products to be used at increasingly higher altitudes without the prior troubles from lack of enough air.

And, on the fuel side, the development of high-pressure common rail (HPCR), allowing for the injection of fuel at any time, continues to be wondrous. In addition to early accomplishments of improving combustion and lowering noise with multiple injections for each combustion event, engines can now develop even more torque these days across greater rpm ranges than ever thought possible by using this system.

Traces of unwanted stuff are still being produced, however — like the previously mentioned NOx, as well as visible particulates (soot). An obvious means to catch those particulates has been to simply fit a diesel particulate filter (DPF) to hold this material until it is dealt with by burning it off on the engine (regeneration) or removal of the filter for external cleaning.

Since someday soon an engine fitted with one of these will require external cleaning, a prudent individual or organization would have already found a convenient cleaning site close by to take advantage of an exchange program for swapping out a plugged DPF for a clean one — with complete programs often set up directly by the engine manufacturer.

Because this required cleaning process adds unwelcome costs and inconvenience, those good engine folk have also worked diligently to develop diesel oxidation catalysts (DOCs) that allow for the conversion of particulates without collecting them. These will work day after day without needing attention, and on some engines, only a DOC is required.

Satisfaction at this point? Well, not completely, because it’s been necessary with Tier-4 Final to really do something with that NOx mentioned earlier. Engine companies and the EPA have been able to come together and develop an understanding as to how selective catalytic reduction (SCR) could be implemented to deal with this invisible, but unwanted, stuff.

The EPA was initially reluctant, because the required diesel exhaust fluid (DEF) must be continually introduced to complete the conversion of NOx in the exhaust stream into harmless nitrogen and water. But the agency relented once a proper distribution network for DEF was forming and companies agreed to engine disabling and shutdown if it was not available at the engine.

Working in Harmony

Well, we have a drilling device that’s mechanically, hydraulically or, perhaps, electrically driven and the site might even need a booming air compressor to supply steady compressed air — and we need an engine or two to provide the required energy. What’s the deal now with one of these latest engines? After all, we just want the engine to turn, turn, turn!

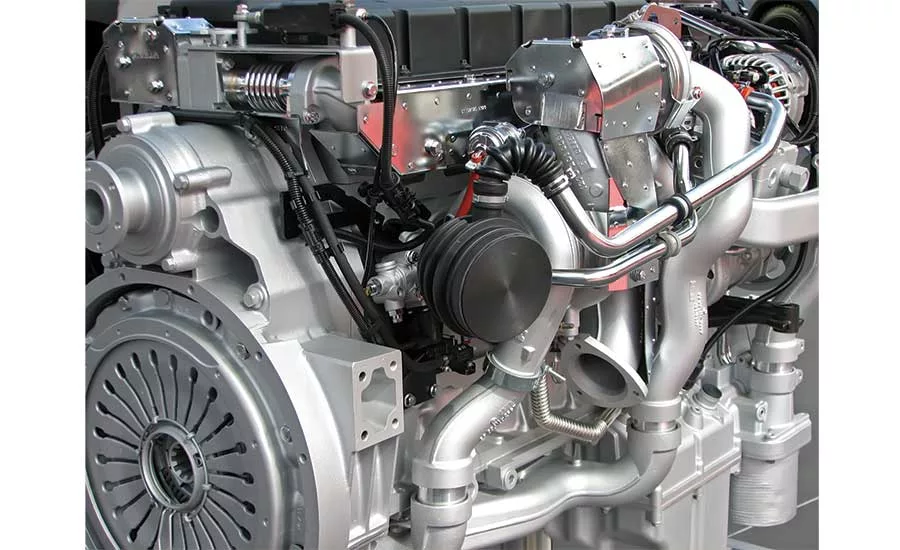

The reality is that it’s been an ongoing and evolving process to find the right combination of components in order to meet the needs for pure performance, good fuel economy and reduced emissions. The EPA does not dictate which of these numerous technologies to use to make a proper engine. It is up to each engine company to find the best combination that gets the job done.

This might sound familiar.

Some recent developments in the latest engine variations offered include reduced or total elimination of EGR, as engines actually tend to breathe and operate best with clean and fresh air.

Another one would be even more power from engines, often allowing for more compact equipment packages.

In fact, a particularly pleasing horsepower point has developed at around 74 hp where it has been possible to assemble emissions-compliant engine packages with just a DPF and, in some cases, simply a DOC and not need to fit SCR packages for further treating of NOx. Some of these engines have been dialed up a bit to produce greater torque, while still staying under the emissions horsepower window.

A particularly pleasing operational benefit of engines over 74 hp, where it has been necessary to use SCR to deal with the lowered levels of NOx dictated by EPA, is that the engines can be tuned to run at higher temperatures for more efficiency (and minimal particulate production), oftentimes resulting in lowered fuel usage.

Keeping the Ensemble Fully Quenched

If we have a look at the fuel section first, we’ll note that the requirements these days are simple in that ultra-low sulfur diesel (ULSD) is all that is needed. It’s helpful to remember that these newest engines are injecting fuel at extremely high pressures — not so much to tear things apart as to force them together for better combustion — and the need for extreme cleanliness is critical. Perhaps a level of cleanliness seldom found on many drill sites.

Surveying the oil section next, we’ll see that most engines these days will be satisfied with the latest CK-4 category, developed not specifically for emissions requirements, but because a more robust oil was needed. In time, some of these engines might require the new (thinner viscosity) FA-4 blends but, for now, those will be needed only on the newest models of on-highway trucks.

Finally, having a look at the recently added DEF section, we’ll want to remember that it’s sensitive in its own way — again to absolute cleanliness and demanding in that, if an engine requiring this precious fluid is starved of it, a prompt shutdown is likely. So it’s helpful to keep a spare (clean) jug nearby for any between-service needs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!