Geotechnical Drilling Key for Nation's First High-Speed Rail

Geotechnical engineering firm Kleinfelder has been contracted to oversee geotechnical exploration of the Pacheco Pass tunnel stretch, a part of the San Jose to Merced section of the proposed high-speed rail. Source: California High-Speed Rail Authority

California is introducing the nation’s first-ever high-speed rail system and the construction of its tunnels relies heavily on core samples from geotechnical drilling.

Meta shales and meta greywacke are the two primary rock types encountered among the four boreholes drilled along State Route 152. Source: California High-Speed Rail Authority

Work for the first-ever high-speed rail system in the nation is underway in California, creating tremendous demand for expertise of all types, including geotechnical drilling. “It is a big deal,” says Byron Anderson, PG, CEG. His geotechnical firm, Kleinfelder, is contracted by the California High-Speed Rail Authority to carry out subsurface investigations as a part of preliminary evaluation for the construction of underground rail tunnels.

The high-speed rail system will ultimately consist of more than 800 miles of rail, with up to 24 stations. By 2029, it will run from San Francisco to the Los Angeles basin in under three hours at speeds of more than 200 miles per hour. It will eventually extend to Sacramento and San Diego. The project has been broken into 10 sections to account for its expansive nature.

Article Index:

The San Jose to Merced project section is in the preliminary engineering and environmental process phase. Part of the first phase of the California high-speed rail system, it will serve as an important link between Silicon Valley and Central Valley. Kleinfelder is conducting the drilling of four boreholes along a 24-mile subsection in Pacheco Pass, a low mountain pass in Santa Clara and Merced counties. Crews are collecting core samples from the boreholes, which extend from 650 to just over 1,000 feet deep.

Approximately 100 geotechnical explorations are planned for the Pacheco Pass range, but the majority are on private property and the high-speed rail authority is working to secure permission to access those areas. In the meantime, Kleinfelder is conducting explorations along public rights of way. “Explorations pretty much for the Pacheco Pass are all going to be fairly deep rock corings,” says Randy Anderson, California High-Speed Rail Authority project manager. “In the valley areas, the explorations would be more shallow soil borings, maybe up to 150 feet and cone penetration tests — CPTs — and seismic CPTs in the valleys, because we’re in the soil in the valleys.”

Project Overview

Crews are using two separate drilling rigs to carry out rock coring using HQ3 wireline coring system from which core samples are brought to the surface for geologists to log. The samples provide extremely valuable information for the high-speed rail design team, Byron says. He is particularly interested in rock properties like rock mass, including fractures. “You may have overall strong rock, but if that rock is highly fractured or breaks easily along weak planes within the rock mass, you have to take that into account in your tunnel design. So we are describing those properties as each core sample comes to surface, and conveying that through boring logs to the design team. So ultimately it will be used in the tunnel design, but as well as in the construction bid process.”

Construction crews will build the tunnels fairly deep in the Pacheco Pass, with low points in the 1,000-foot range, Randy says. The four borings Kleinfelder is working on — in four separate locations, no more than one to two miles apart — total about 3,320 feet. Crews have completed a little more than 2,400 feet with an estimated project time of four months altogether.

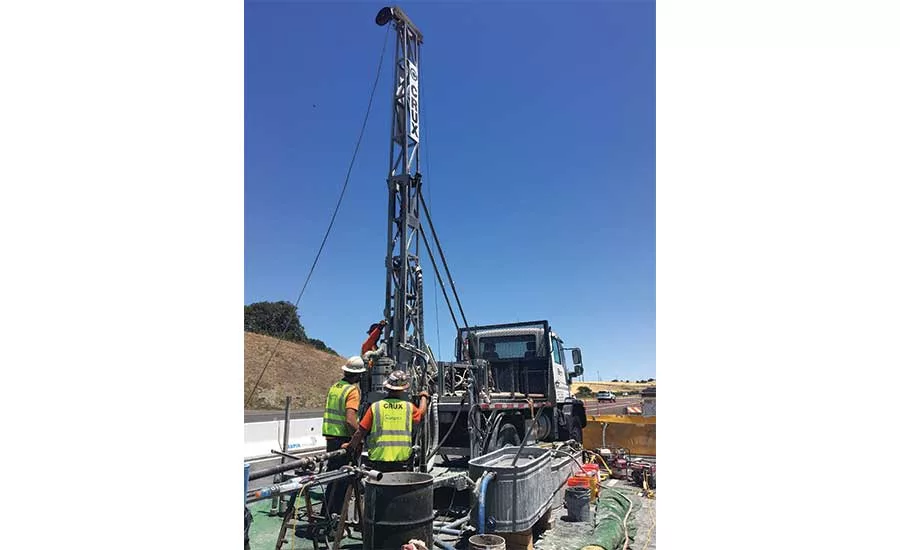

The crew is working 10 days on, four days off. Shifts are typically 10 hours and often extend to 11 or 12 hours. The crew consists of a head driller and two helpers. A supervisor moves between the two rigs, troubleshooting and providing oversight. In addition, engineering geologists are on hand to log the core samples. A DMW 65 track-mounted drilling rig is used for tight spaces along the highway. It can drill down to 2,400 feet. A Burley 6000 drilling rig is used in the less confined work space. HQ-sized rod being used to advance the core holes produces a borehole diameter of about 3.8 inches.

Site Planning

With all four boreholes located along State Route 152, site planning is an important aspect of the project. Most sites feature existing access roads that ranchers have developed, but some don’t. Since the high-speed rail authority wants to minimize new path construction, helicopter access is being considered in those locations. It would involve airlifting equipment.

Safety is an important concern for work near a busy highway with a lot of truck traffic. The four-lane, divided roadway consists of two lanes going east and two lanes going west on a curve alignment. With this in mind, Kleinfelder recommended the use of K-rail. The concrete barriers, which are craned into position, provide increased safety for crew members, but they aren’t the end-all, be-all. “We have safety meetings every day before we start our drilling and one of the items we discuss is that our crews do not rely on that barrier and they try to work away from the roadway as much as possible. We try to do as much work as possible as far away from that roadway as we can,” Byron says.

The Authority is also working closely with Caltrans to establish lane closures; setup for each borehole requires it. In addition, the Pacheco Pass area reaches temperatures of 100 degrees in the summer months, so keeping crew members cool and hydrated is vital.

Ground Conditions

From a geotechnical standpoint, Byron emphasizes the importance of understanding the geological formation. Much of the Pacheco Pass is underlain by mélange of the Franciscan Assemblage, which he describes as often chaotic. “It’s a mixed bag. Our first boring, my loggers could barely keep up they were moving so fast. It was just great rock. The second and third ones, they’ve encountered some trouble zones with caving and squeezing ground due to the sheared nature of the rock. … These zones have slowed us down a bit.”

The primary rock types encountered are meta shales and meta greywacke. They are both ocean-floor sediments that have been exposed to intense heat and pressure. “What we’ve seen so far in all of our borings are these two rock types very thinly interbedded with each other,” Byron says.

In unstable zones, hole stabilization is required to advance the core borings to their full depth and to obtain the core samples. Open-fracture rock systems pose challenges because they often lead to fluid loss. Such setbacks have to be considered ahead of time so they are accounted for in scheduling, and ensuring the right equipment is made available. “They are an experienced group,” Byron says. “There are a lot of tunnels out here and you want crews that have worked on these types of projects in the past. Having that experience is extremely valuable.”

In a broader sense, it is important to remember that such geotechnical drilling projects do not reveal exact ground conditions. “These are little pinholes relative to the entire alignment. So you get what you can, but it is limited exploration work,” Byron says.

Post Drilling

After geotechnical drilling comes lab testing; then, geotechnical data reports, interpretive reports and baseline reports. Ongoing monitoring will take place as well. “We’re putting in these vibrating wire piezometers,” Randy says. “So we’ll have continued monitoring of these devices that have been installed.”

All four of the boreholes along the 24-mile Pacheco Pass stretch will receive vibrating wire piezometers (VWP). VWPs reveal information including groundwater pressure, elevation and temperature — important data for tunnel design. “For the tunnel lining, you have to put that additive load of the water pressure, along with the rock or soil load, on your final lining design,” Randy explains. “If you have 1,000 feet of water head, you can imagine the pressures you have to design for. We want to know what the ground temperatures are down at those tunnel elevations because that could have an impact on our inside tunnel temperature and climate control inside these high-speed rail tunnels.”

Geologists look for red flags in the core samples like weak zones and swelling zones. Engineers pay attention to rock structures that could lead to unstable conditions relative to tunnel design, as well as construction worker safety. In addition to rock hardness, geologists are on the lookout for hazardous minerals like naturally-occurring asbestos and gases.

Fortunately, two existing water tunnels — the Pacheco water tunnel and Santa Clara water tunnel — are fairly close to the area of geotechnical exploration and lend additional subsurface data without requiring drilling, Randy says. The rail authority has the construction information and the boring information from both tunnels to refer to. “So we have some really good construction and boring information from these existing two tunnels that will become valuable data for the bidders and for us because it gives us a better idea of the formations we’re dealing with.”

As the broader California high-speed rail project continues and additional areas call on geotechnical drilling, Randy points out that workflow efficiency will be optimized. Lessons learned with respect to technical challenges, contract management and scheduling at this phase will help with the other two major tunneling segments in the future: the Tehachapi Mountains and San Gabriel Mountains in southern California.

Byron and Randy say they are honored to be a part of such a historic project. “You can imagine the demand and the opportunities it’s putting out there for these construction firms and engineering firms and geotechnical firms and disadvantaged businesses and small business,” Randy says. “We’re doing something that hopefully the whole United States will take off on, on high-speed rail around the United States.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!