Tips for Calculating Setback in Horizontal Drilling

A lot of geometry comes into play when determining a proper setback distance in horizontal drilling.

Source: David S. Bardsley

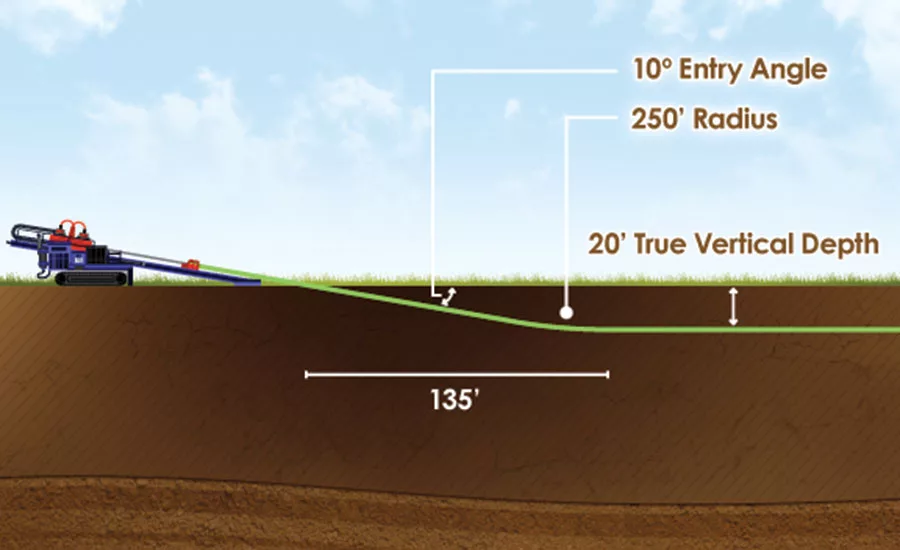

In a past column, we provided a general overview of horizontal wells and their uses for environmental remediation applications. Now it’s time to get a little more detailed. One of the first questions usually asked during the initial phase of a horizontal well project is, “What’s the distance from where the bit enters the ground to the start of the screen section?” Or, “How deep do I have to drill vertically before I can turn to go horizontal?” This starts to raise flags with the horizontal drilling contractor because what the consultant really means is either “My site is tiny and I’m not sure if the rig will fit,” or “I didn’t know that you start drilling at an angle.” What we’re talking about in horizontal directional drilling vernacular is the setback distance.

As a rule of thumb, the minimum setback distance can be estimated using a 5:1 ratio. For every 1 foot of depth, figure about 5 feet of horizontal displacement. So a 20-foot-deep well would require approximately 100 feet of setback. Review the figures in the table on this page and you’ll see what we’re talking about. A word of caution needs to go here: Always remember that the drill rig still needs to fit on the site and some rigs are really long — over 55 feet. To make matters worse, some of the longer rigs are trailer-mounted, which means additional room is required to manipulate the equipment into the proper position. What’s more, depending on the angle at which the drill rods enter the ground, as much as 15 feet of drill pipe may be exposed between the front of the rig and the actual entry point.

As a rule of thumb, the minimum setback distance can be estimated using a 5:1 ratio.

The setback calculation seems pretty simple: Just use the 5:1 ratio. Well, maybe not. Let’s look at our diagram again. You’re good at geometry right? You think to yourself, what if I change the entry angle or the build radius, won’t that have an effect on the setback distance? Well, you’d certainly be correct. But before you get too carried away, we need to think about the most important item that determines the setback distance: the drill pipe. We use steel drill pipe in our operations, and steel is flexible. But at some bending radius the pipe goes from elastic deformation (it will spring back to its original shape) to plastic deformation (permanent bend or change in shape). If you keep bending the pipe through the plastic deformation phase, it will ultimately buckle and then break. And bent/broken drill pipe is never a good thing. So, now it’s time for another rule of thumb: For every inch of outside diameter (OD) of steel drill pipe, estimate it can be bent in a 100-foot radius. Therefore, if we’re drilling with 2-inch diameter drill pipe, we can safely put it in a 250-foot radius; 5-inch drill pipe, a 500-foot radius, and so on.

Why would we use one drill pipe size over another? Could be several reasons. For example, the larger the borehole/well diameter the larger the drill pipe required. Also, the more challenging the geology — think gravels or bedrock — the larger the drill pipe. And, finally, bigger rigs require bigger tooling.

For more on horizontal directional drilling, click here!

Before we go any further, a word of caution: Designing the bore plan at the tightest drill pipe bending radius is risky. If for some reason we can’t steer to the profile, we have no “wiggle room” to go tighter (we call that “busting a radius”). The result will either be a deeper screen start or a lengthened setback distance and shorter screen section. Bottom line, we always want to plan the bore path with a bending radius greater than the drill pipe minimum. This will give us some “wiggle room” to meet the bore plan if we encounter issues during drilling.

Now that we know the drill pipe has a minimum bending radius, let’s go back and play with the geometry. Assume that we have a drill rig that can enter the ground (entry angle) between 10 degrees and 22 degrees above horizontal, drill pipe that can’t be placed into a tighter radius than 250 feet and a screen start depth of 20 feet. Review the table below and see how the setback distance changes as we vary the entry angle.

| Entry Angle Above Horizontal | Build Radius in Feet | Setback Distance in Feet |

|---|---|---|

| 10° | 250' | 135' |

| 14° | 250' | 110' |

| 18° | 250' | 101' |

| 22° | 250' | 98' |

As you see in the table, by modifying the entry angle we could potentially change the setback distance from 135 feet to 98 feet. Note that the 18-degree and 22-degree entry angles work well with our 5:1 ratio. However, that rule of thumb does not hold true with the shallower entry angles.

Finally, if you’re reviewing a site and don’t think you have the proper setback distance, don’t panic — call someone who is familiar with horizontal well design. Drillers are a clever bunch and we may be able to squeeze the well in anyway using some other options (remember, many rules of thumb can be broken).

Hopefully, this has helped you visualize the geometry of a horizontal well, and not made the setback distance “clear as mud.” Just remember, the 5:1 ratio should be used as a rule of thumb to determine the minimum distance from the drill pipe entry point to the start of the screen section. To get a more accurate determination, contact a reputable horizontal drilling contractor with well installation experience: They can quickly review your project parameters to determine the well geometry.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!