Well Pits a Part of the Past for Most Drilling Contractors

|

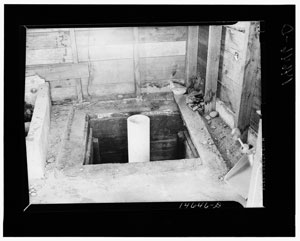

| Well pits are against most health codes these days, so younger drilling contractors may not be familiar with them. Source: Library of Congress, Prints & Photographs Division, FSA/OWI Collection |

The use of well pits came from a need to combat freezing temperatures here in the north country. You readers who live where it never, or seldom, freezes or gets below 32 degrees Fahrenheit probably are not that familiar with them. It is perhaps fitting that we recently experienced extremely cold weather here in southern Michigan. As I write this near the end of January, we have been through a real severe cold snap. In the last couple weeks we had daytime temperatures right at, or even a little below 0 degrees. Now that is actual temperature. Chill factors were roughly 25 degrees below zero, night time temperatures were even lower and water can’t really tell if it is day or night — all it knows is that below 32 degrees it will freeze solid, expand and break things.

As a result of these conditions, which have been around in the north country forever, people figured out a way to, in effect, beat the freeze. They dug a hole in the ground, perhaps shored up the sides, put on a roof of some sort and they had a freeze proof place. In my part of Michigan frost will go down about 3½ feet in a normal winter. It is good policy around here to bury water pipes at least 4 feet deep and I always liked to go 5 or even 6 feet deep. A driveway or even a walkway used by people will send frost below the nomal 3½ feet. In these locations — especially a driveway — a minimum of 6 feet is an effective bury depth. Strangely, north of us they experience less frost than we do in some places as they can get snow as early as late September and snow is a good insulator. I have been told by my friends in the Dakotas and Minnesota that 7 or 8 feet is a good depth to bury pipes around there.

With the knowledge of what it took to be below the frost line, people here in southern Michigan and all other cold areas began constructing well pits. This would be a space in the ground dug around the well casing. A good well pit would be 6 feet wide by 6 feet long by 6 feet deep. The walls would be constructed of good concrete block or poured concrete, the floor would be poured concrete, the roof would be concrete or perhaps metal rafters covered by some sort of weather-proof roofing. This pit would have a drain of at least 4 inches in diameter naturally coming to the surface, a couple of pipes for air circulation being 2 inches or greater diameter with U bends at the top protruding through the roof with one pipe ending near the floor of the pit and the other just below the inside of the roof. The pit would also have some sort of moisture-proof ladder below an access hatch so a workman could get down inside. An electric light or lights would be desirable, if not necessary. A pit to this design would pretty much ensure freeze-proof operation and, at risk of upsetting my public health friends, actually work pretty well.

The problem was, and still is for that matter, that only about one pit in 200 was built like this. Most were really not quite deep enough or large enough, so the pumping equipment was crammed into too small of a space. Almost none had an adequate drain. Usually these were plugged up or never did work. In an attempt to get around a drain some people constructed these pits with a sump and then installed a sump pump. This was probably OK most of the time, but if the sump pump failed or the power went out we had, in effect, a small swimming pool. Most of the roofs were inadequate, leaky and rotten. Most every one of these had a poor ladder for getting down inside. A favorite of many owners was to place a wooden step ladder under the access hatch. Over time moisture would rot these ladders and many, many times in my career I went through a rotten rung on a ladder but, fortunately, was never hurt really badly when this happened.

One of the major drawbacks of a well pit, though, was the moisture that I just wrote about — condensation on walls, roof and anything inside was a real problem. When the industry used surface pumps like piston, rod or jet pumps, this did not seem to be a huge problem. When the motors on these pumps ran they created some heat and their cooling fans dried them out. When the submersible pump became popular there was no heat at the surface and no fan either. Three-wire pumps, which used a control box, were especially vulnerable to condensation but pressure switches, starters and disconnect switches were also badly affected by moisture. There was really no way other than, perhaps, a dehumidifier to keep the inside of the well pit dry and I never saw one of these installed, ever.

Some of the other drawbacks of these pits were freezing when the access hatch was left open and, as I said, difficult access by the service man. The worst drawback was they tended to flood, sending contaminated flood water down the well casing even if it was equipped with a so-called sanitary well seal. Because these pits were relatively warm and cozy, they became the winter home of assorted squirrels, chipmunks and, yes, snakes. Homeowners also figured out that this was a great place to store potatoes, carrots, onions and other vegetables they had grown in their garden. With this storage, many times a service call turned out to be a trip to the vegetable department … and a smelly one too. While banned by most public health codes, I believe most of these pits are now considered confined spaces and illegal under OSHA rules. That, friends, is a good thing. If I never have to go into another well pit — and yes we still have some — it will be too soon.

I included my monthly weather report earlier, so I will end on the comment that next month I will talk about some so-called innovative ways to make well pits. In the meantime, work safe and stay out of these darn things if at all possible.

For more John Schmitt columns, visit www.thedriller.com/schmitt.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!