PFAS Adds Complexities to Environmental Drilling Jobs

PFAS contamination is often high at sites that manufactured the substance or in areas like military bases where it was used in fire suppression foam.

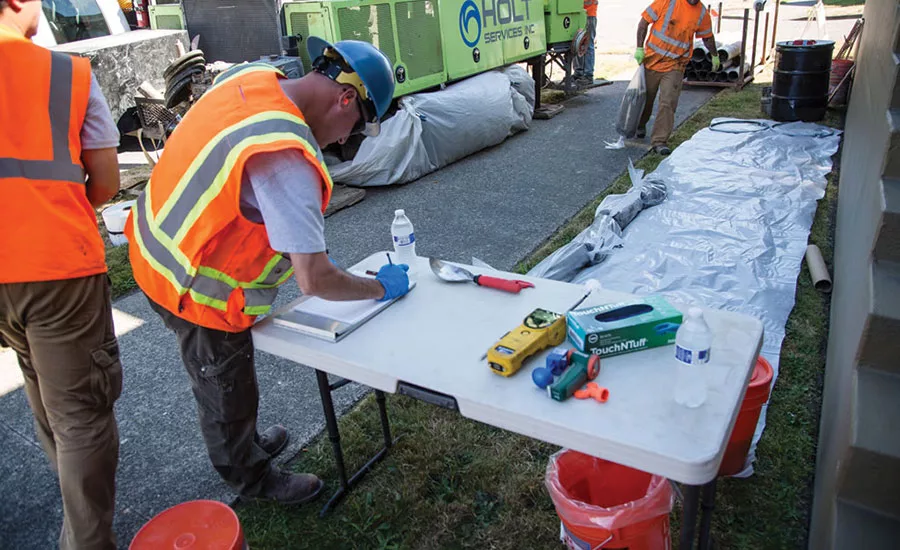

Source: Holt Services Inc. photos

There’s a range of best practices to use when investigating sites for possible contamination.

In January 2018, the documentary “The Devil We Know” debuted. The film is about toxic chemicals being dumped in a West Virginia town’s water supply and the residents’ fight with DuPont Corporation to try to hold it accountable for the contamination. But this story isn’t new. It starts in 1938 with the invention of man-made chemicals designed for non-stick cookware. Companies found more ways to use these chemicals over the years to produce food packaging, stain and water repellents, and foam fire suppressants. PFOA — a toxic chemical in Teflon — is so widespread, the documentary claims it is in the blood of 99 percent of Americans.

PFAS contamination is often tied to sites that store or use flammable and combustible materials, and thus use fire suppression foams containing PFAS for firefighting missions. Foams are a better suppressant for these highly combustible fires because the foam can cool the fire, separate the flame and ignition source from the surface, suppress the vapors and prevent reignition.1 The foams are great for putting out the fires. However, they’re also permeating our groundwater supplies and finding other pathways to our most precious resource. This, in turn, adversely affects the food we eat. Thankfully, awareness of PFAS chemicals and their harmful effects is on the rise and new steps have been taken to reduce exposure and combat their presence in our natural environment.

Over the past few years, Holt Services Inc. has had the opportunity to work on several projects investigating and/or remediating the threat of per- and polyfluoroalkyl substances (PFAS) to the environment. Although PFAS is not necessarily a new chemical, its widespread presence and harmful effects on the environment have become alarming issues. Studies have shown that large doses of PFAS-related chemicals can cause reproductive, developmental, liver, kidney and immunological effects in laboratory animals.2

Environmental and engineering consulting firms continue to make headway in the identification, containment and treatment of PFAS contamination. New policies have also been introduced to help deal with and protect against human exposure, and with the ongoing threat to the environment.

Under the direction of these consulting firms, Holt Services is working to combat the PFAS problem. Holt provides the most technologically advanced drill rigs in the environmental market, along with drill crews who have decades of experience working with and handling harmful contaminants. Having managers with PFAS experience is a vital piece in the success of a drilling project in which the contaminant you are trying to identify and remediate is found in many of the products, materials and equipment commonly used in the drilling industry.

Here are some things to think about before you get into the field.

Inspect the Manufacturer’s Specification Sheet

A lot of commonly used groundwater pumps and tooling have grips, fittings, seals and other components made up of plastic materials that can contain or could have been manufactured and exposed to PFAS chemicals.3

Common Level D personal protective equipment (PPE) should also be inspected. This includes:

- Safety vests

- Steel-toed boots

- Hard hats

- Gloves

- Rain gear

PFAS is used in a lot of different manufacturing processes and is commonly found in stain and water repellants often used in PPE.4

Ensure there is no direct exposure with samples to prevent cross contamination.

Check the MSDS

Review the MSDSs to ensure the well materials used in the field do not contain PFAS substances. The most commonly found and best studied PFAS are perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS).

Some materials you’ll want to look at include:

- PVC casing and sleeve

- Tubing

- Grout

- Bentonite

- Cement and concrete

- Fuels

- Oils

- Grease

Water Supply

PFAS chemicals do not readily breakdown in the environment and are water soluble. As a result, there are very low levels of PFAS in many areas of the environment. Contamination levels may be higher near facilities that manufactured, disposed of or used PFAS. Since water is often used to decontaminate equipment and assist with drilling activities, your water supply should be tested for PFAS.

Storage

Take care when storing materials and equipment that will be used in sample collection. Avoid storing materials and equipment in areas where there is a possibility of contact with materials containing PFAS.

Environmental contractors can do their part in the complex fight against PFAS and PFOA substances. A thorough check of equipment and supplies used on the jobsite can help contractors ensure the best samples and help reduce exposure to their crews and beyond.

Sources:

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!