Flocking Agents Help Drillers Combat Cloudy Cameras

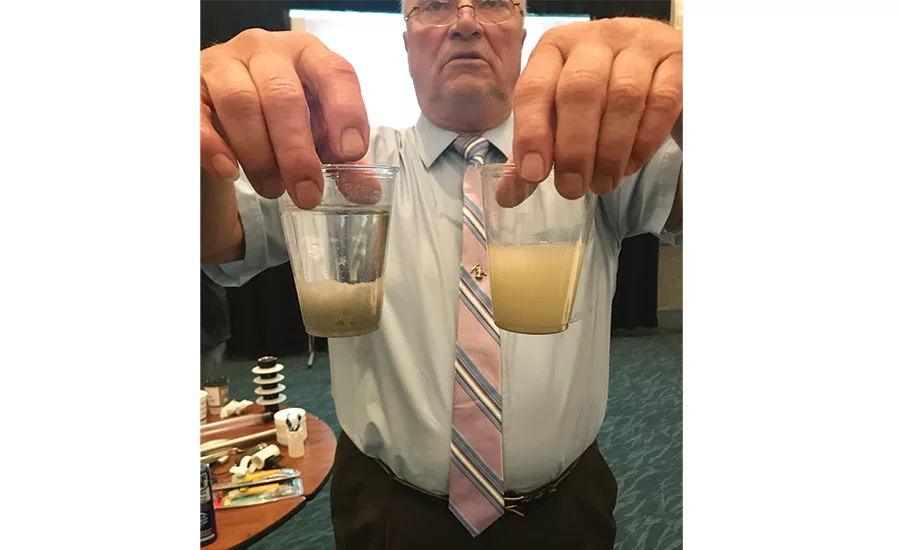

The cup on the right is a cloudy sample. The cup on the left is after agitation of a small amount of flocking agent, presenting crystal clear water to be able to video the casing through.

Source: Alexis Brumm

This story starts in a sporting goods store.

A man walked in to find an Aqua-Vu fishing camera on the shelf. He picked it up, inspected it and realized that it had a better picture quality than the $1,500-a-day camera trailer that he was renting. This man always wanted to own a downhole camera, but they were pricey — starting at over $20,000, upwards to $60,000. The Aqua-Vu was only $395.

So he met with the inventor and designer of that camera, Jeff Zernov, who said he would build a downhole camera if this man could sell it.

That man was Raymond Roerick, a Vietnam vet who started in the water well industry in 1975. And that camera? The Well-Vu.

“Today, the Well-Vu is a common item on most service trucks, and we have a large number of customers who have two of our cameras,” he says.

Roerick has owned a couple businesses in that time — the most recent being Pumps Plus Inc., a family pump service company — and is now the international sales manager for Well-Vu cameras. The biggest complaint he’s seen from customers trying to make a video inspection of a well after pulling the pump is that the camera works well, but when it goes into the water, it looks out of focus or hard to see.

Roerick has spent the last 10 years working with flocking agents, trying to fix this problem. Though not without its challenges, he’s come up with a solution.

“The biggest drawback was introducing chemicals into domestic water wells and contaminating the well and/or the aquifer,” he says. “The good news is now we can offer a flocking agent that has NSF approval for use in domestic wells.”

Clarifying agents are used to remove suspended solids from liquids by inducing flocculation (the solids begin to aggregate forming flakes, which either precipitate to the bottom or float to the surface of the liquid, and then they can be removed or collected).

These particles collide and collect together, and the larger and heavier particles are called flocs. Flocculants, or flocculating agents, are chemicals that promote flocculation by causing suspended particles in liquids to aggregate, forming a floc.

For example, a flocculant may be used in swimming pool or drinking water filtration to aid the removal of microscopic particles that would otherwise cause the water to be turbid (or cloudy) and would be difficult to remove by filtration alone.

National Driller spoke with Roerick to learn more about flocculants and their usage in drilling applications.

Q: What is the purpose of flocculation?

A: It’s simply to facilitate clarity within the water column to provide a viewable video recording/inspection of the well. Coagulation and flocculation bring the ultra-fine particles together, increasing the density so they will settle to the bottom.

Q: How do clarifying agents remove suspended solids from liquids?

A: In this case, the clay-based flocculants do not remove the suspended solids. They coagulate the fine suspended solids to form a floc that is larger and heavier, causing it to fall to the bottom of the well. The removal of the suspended solids comes from well development after the camera survey.

Q: What are the most common flocculants for drilling applications?

A: The most common flocculants in drilling applications are generally polymers. Flocculants come in a wide range of molecular weights and charges. Anionic, nonionic and cationic polymers are used as both flocculants and coagulants. There are only a few places where alum (aluminum sulfate) is still used, but very few.

Q: What factors play into the time frame for a flocked well to clear enough to use video?

A: Two factors that play a role in the time frame for a flocked well to be clear enough to use video are the amount and type of suspended solids in the well. A few other factors are the agitation energy of the water in the well bore, water temperature and water quality. Usually, upon the completion of agitating/mixing, the water is clearing up already.

Q: How can you tell if you need a flocking agent?

A: The first clue is usually if you’re lowering the camera into the water column and the picture goes dark. Water sample clarity and pilot testing is another way to tell. Any turbidity in the sample and how long it takes to settle will also tell you a lot. Some other big problems are high TDS (total dissolved solids), iron, manganese and tannins.

Q: What is the process once clarifying agents are added?

A: Mixing or agitating is critical. Agitate the water column with low air of surging to blend the flocculent. Then, mixing by installation of a pump and pumping back into the well, circulating the water. Allow flocs to form and settle (note that the size of floc and depth to settle will determine the time needed).

Q: What are some common mistakes people make when using flocculants in well applications?

A: One of the most common mistakes people make is they over-treat. More is definitely not better when it comes to flocculants. They also try to treat water with too high of solids content.

Q: What are the fixes for those mistakes?

A: Pilot testing at the site. They should pull a small sample and do a shake test, paying attention to the application rate.

Q: What are some troubleshooting tips if flocculants don’t work as expected?

A: Look at the pH level and any dissolved solids that may be interfering with the function of the polymer. You may have to move to a different charge on the polymer if it didn’t work the first time.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!