Questions, Answers About Grouting and Sealing on Drilling Jobs

On the jobsite, drillers have better grouting options than ever before. It is important to use the best one available for the application, and if you have questions to consult the professionals.

Source: CETCO Drilling Products

I am sure that many of the readers of National Driller magazine have at one time or another talked to a CETCO Drilling Products employee or one of our reps. Perhaps it was on the phone, or at one of the many open houses or tradeshows that we attend. The number of products available to drillers is constantly growing and, therefore, they face a never-ending learning curve. We spend a large amount of time educating customers on the use of bentonite drilling fluids, and polymers and additives, as well as grouts and sealants. This column addresses some of the frequently asked questions we receive.

Q. How long does the coating on coated tablets last before they start to hydrate?

A. Coated tablets have a coating that takes 30 minutes to dissolve prior to the bentonite making contact with the water. The coating ensures that the bentonite does not start to swell in this time, allowing the tablets to sink long distances in the water column prior to swelling and possibly bridging.

Q. Does the coating change the chemistry of groundwater?

A. No, the coating does not change the groundwater chemistry. This makes coated tablets a good choice to use in order to seal a monitoring well directly above the filter pack.

Q. How far will bentonite chips fall before they bridge?

A. This is not an easy question to answer, since it depends on the size of the hole or annular space, how the well is drilled and the static water level. Drillers have placed chips over 500 feet in the right circumstances.

Q. How can you reduce the chance of chips bridging in the hole?

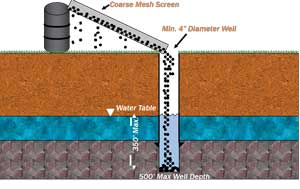

A. The best way to reduce the chance of bentonite chips bridging is to screen the fines before placing them in the hole. As the bags of bentonite chips are handled and travel, they can produce fines that increase the chance of bridging. Figure 1 shows that pouring chips at a slow, steady rate over a coarse screen is one option for reducing fines.

Q. How do you know how much bentonite is required to grout a hole or fill an annular space?

A. The easiest way is to utilize online calculators, such as the Cetco Grouting & Sealing Calculator on www.cetco.com. Other bentonite manufacturers will have their own. Cetco and many other bentonite providers also have mobile phone apps that will do calculations in the field. There are also very useful field application cards that list the amount of bentonite chips or grouts required per linear foot.

Q. Can you pump grout from the top of the hole?

A. No, a tremie pipe should be used to pump the grout from the bottom of the hole to the top. See Figure 2.

Q. What size tremie pipe should be used?

A. It depends on the diameter of the annular space or hole but, typically, a 1.25-inch tremie works in most instances.

Q. Can grout get stuck in the tremie pipe?

A. Yes. This is especially a concern when drilling in hot weather. If the tremie pipe is sitting in the hot sun or warm water is used to mix the grout, try running cold water through the tremie line first. A slug of PHPA polymer pumped through the tremie line can also be helpful.

Q. Is the weight of the grout important?

A. Yes. The grout needs to be heavy enough to displace the fluid in the hole. It is also important to test the drilling fluid to be displaced by the grout to ensure it can be adequately displaced by bentonite grout. High-solids bentonite (i.e., 20 percent solids) grouts normally weigh around 9.5 pounds per gallon. If a drilling fluid is high in drill solids (more than 9 pounds per gallon), it can lead to inadequately grouted wells. For example, when pumping a 9.5-pound-per-gallon high-solids bentonite grout into a well with drilling fluid that is 10.5 pounds per gallon, the lighter high-solids bentonite will float to the surface quickly instead of displacing the drilling fluid. Make sure to test the grout with a mud balance before placement to get the mud weight. Then test again when the grout reaches the surface to make sure that you have displaced all of the water or drilling fluid.

Q. How do I know what type of pump to use for grouting?

A. First, centrifugal pumps should be avoided for all bentonite based grouts because they create too much shear, causing bentonite grouts to flash set and plug everything. Progressive-cavity (Moyno style) pumps work great with 30-percent solids grouts, as well as 20-percent solids one-step grouts (powdered or granular). Avoid using progressive pumps for two-step grouts that use a mixture of water, PHPA polymers and granular bentonite, because the pump rotor and stator will crush the granules of bentonite and the grout will flash set. Thermally-enhanced grout mixed with silica sand is too abrasive for progressive cavity pumps. If using thermally-enhanced grouts, make sure the pump is designed to handle abrasive material. Piston pumps work great for all types of bentonite grouts.

Proper grouting and sealing of the annular space of a well or an abandoned well is one the largest responsibilities of a well contractor. Every well contractor has a duty to ensure that a well is properly sealed or abandoned to prevent surface contamination or the mixing of aquifers.

Clean water is the most important resource that we have — let’s ensure that we preserve it for future generations. Next month’s article will review frequently asked questions regarding the drilling fluids required to stabilize and keep a hole open. Happy drilling and keep the questions coming!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!