Tips for Job Safety Analysis on Drilling Jobs

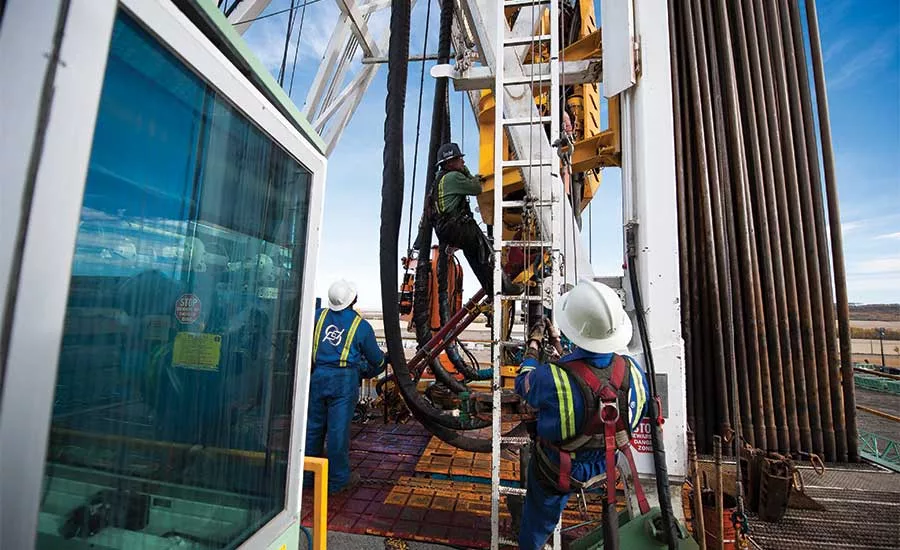

Whether you’re on a remote fracking rig, a suburban HDD job or a rural water well jobsite, having a documented job safety analysis can minimize risk for crews.

When done well, a job safety analysis (JSA) is an effective tool for identifying and addressing worksite hazards before incidents occur. Yet all too often, the JSA process is incomplete or inadequate, or findings are not shared with employees. Performing thorough JSAs for each job or process, updating them regularly, and providing employees with easy access to the documentation is essential to generating greater awareness of safety risks.

Here we review the steps for completing an effective JSA, and how technology can make it easier to complete the process.

Step 1: Job Selection

Selecting the job to be analyzed sounds simple, but it’s a vital consideration for employers with limited time and resources to analyze all of the various jobs associated with their operations. Also important to keep in mind is that each JSA needs to be revised with the introduction of new equipment, raw materials, evolving processes and work environments. A good best practice is to prioritize the jobs to be analyzed, so even if you can’t analyze them all, the most critical ones will have been examined first.

Generally, JSAs should be prioritized using the following criteria:

- Jobs with the highest frequency or severity of incidents and injuries

- Jobs with the highest potential for injury or illness

- Newly implemented jobs and processes workers are not yet accustomed to performing

- Recently modified jobs and processes

- Non-routine jobs where workers may not have high awareness of hazards

Step 2: Job Task Breakdown

Each job must be broken down into a clearly defined sequence of individual tasks. Avoid defining individual job tasks too narrowly or too broadly; generally speaking, a job should contain no more than 10 individual tasks. Jobs that exceed this number should be separated into two or more separate phases. It’s important to maintain the proper sequence of job tasks so potential hazards are identified in the order they are encountered by employees.

A good best practice is to have someone familiar with the job directly observing and recording the series of individual tasks as an experienced employee performs them. This helps ensure all steps are being evaluated, and that tasks are being performed in the proper sequence with a high level of precaution to more easily identify any unforeseen hazards.

Step 3: Identify Hazards

Hazards should be identified soon after the observation and breakdown is completed, while the sequence of job tasks and potential hazards are still fresh in the minds of all participants. During this process, review the sequence of job tasks and answer questions that reflect the unique potential hazards and work environments associated with each job. Employees performing the tasks should provide input as every possible outcome is considered.

Step 4: Develop Preventive Measures

There are four common strategies used in developing preventive measures for hazards associated with job tasks. Listed in order of priority, they are:

- Eliminate the hazard: Widely considered the most effective, longest-term solution to improving job safety (but also the hardest to enact), this involves modifying or selecting alternative processes, hazardous substances, work environment or equipment.

- Contain the hazard: Employing the use of machine guards, enclosures, safety mechanisms and other engineering controls to prevent contact or proximity to hazards.

- Revise work procedures: Taking steps to eliminate hazardous tasks, change the task sequence, or add steps where precautionary measures are appropriate.

- Reduce hazard exposure: Focuses on minimizing hazard exposure with personal protective equipment (PPE), and providing injury and illness treatment like first aid and eyewash stations.

Step 5: Documentation & Communication

Upon completion, the JSA findings should be documented and made available to employees. Too often, employers spend time and effort creating JSAs only to have the documents disappear into a binder or filed away onto a computer hard drive and forgotten. JSAs need to be made readily accessible to inform employees about the hazards in their job tasks and what preventive measures will help keep them safe.

How Technology Can Help

Maintaining a good JSA program is an ongoing and ever-changing process. Today, a good risk analysis or EHS software solution can help simplify the creation and management of JSAs for any job, and ensures that the risks are being communicated to employees and prioritized for mitigation. Single-source, cloud-based incident management software that collects data around recorded injuries, illnesses, near misses and hazards also makes it faster and easier to identify trends and risk factors. With greater visibility of critical incident metrics, you can more easily identify areas where a new or updated JSA is needed.

Better insight into the hazards workers face leads to more effective risk management. By facilitating communication, participation and engagement among everyone involved on the worksite, JSAs offer the opportunity to identify unforeseen hazards and increase support for a stronger safety culture.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!