Tips for an Effective Gravel Pack

Gravel packs are a well construction method that allows drillers to achieve maximum efficiency with minimum sand production. They are most often used in unconsolidated sand aquifers, such as most of the coastal plains areas of the world, or in unconsolidated alluvial formations. Often, these aquifers are made up of poorly graded and poorly cemented sands, and the wells will produce sand during pumping.

Some drillers just use a finer slot screen to keep out the sand. This works if the well doesn’t have to make much water for its intended purpose. If a formation is capable of making 100 gpm, but you are only going to install a 10 gpm pump, you can just put in a fine slot screen to shut off all the sand and part of the water. This is common in house wells where competitive pressures keep costs down, but it hurts the efficiency of the well.

High-capacity wells, such as irrigation or commercial wells, obviously need to produce more water. Often, the pump is not selected until the well is drilled and tested for production. Then the maximum size pump is installed. This requires wells of maximum efficiency. A good gravel pack is one of the best ways to achieve this.

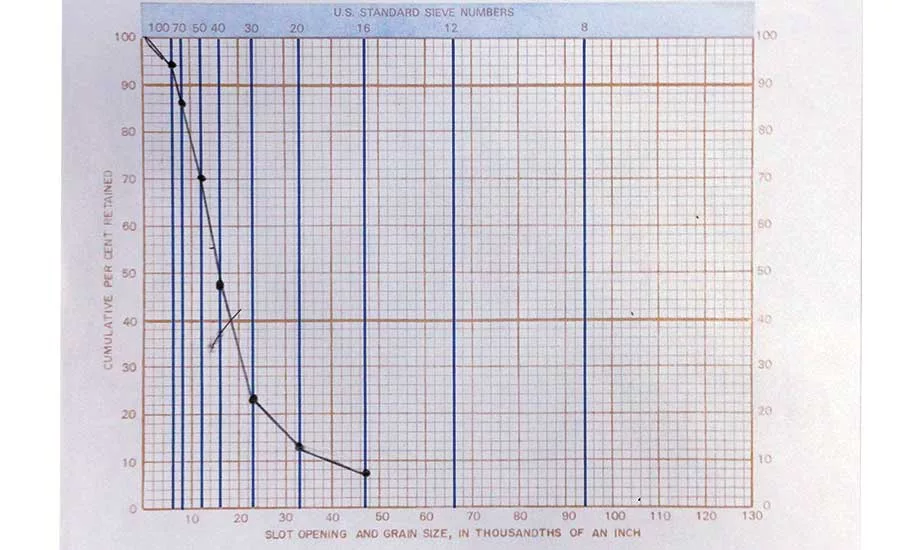

The first step in a good gravel pack is good samples. A small-diameter test hole is drilled and carefully sampled. Accurate depths and samples are important. Often, the test hole is drilled long before the final well is drilled to allow time to get the right screens and grade of gravel. Samples should be carefully marked as to depth. The next step is to “screen the sand.” This involves running the samples through a set of progressively finer screens, weighing what each screen retains and making a graph of the results. This will help you decide the appropriate gravel and screen size. Different companies have different formulas for the relationship between the formation size, the gravel size and the screen slot size. Most major screen manufacturers will run your samples and help select the proper screen size, or you can do it yourself.

Several years ago, I was drilling a lot of wells that needed to be gravel packed, so I bought a set of gravel sieves, scales and all the equipment I needed to do my own analysis. I powered my sieve with a 12-volt motor so I could do my analysis on the tailgate of my truck at the rig. This worked very well, as I usually had an idea of the screen slot size, and kept several on the truck.

One year, I drilled a test hole in the middle of the winter and didn’t feel like standing around running my sieves in the cold, so I took all my samples home. Lottie was at work, so I used her cast iron frying pan and stove to dry my samples before bringing them in my office to analyze. Since my sieve set was 12-volt, I went out and got the battery out of the welder. I put it under my drawing board, and hooked up a battery charger to keep it going. I ran my sieve analysis, figured out what screen I would use and promptly forgot about the battery and charger under the drawing board. This was in a brand new house that we had just moved into about two weeks before.

A couple days later, I heard a loud BANG and went in to discover that the battery had exploded! It blew a perfect, battery-sized hole in the floor. The bottom of the battery was sitting in the crawl space and the walls were covered with shrapnel and battery acid. I knew I needed to do something before my bride got home. I intended to get a piece of plywood and fix the floor, but in the meantime, I just covered the hole with a spare carpet remnant I had. Then, being me, I promptly forgot about it. This might have worked out, except Lottie happened to go in my office looking for something, and accidentally stepped in the hole. She was not happy. Before I got home, she hired a carpenter to fix the floor, and told him to bill me. I paid it without complaint.

Meanwhile, back at the rig … usually a gravel-packed well will be drilled larger than standard to allow room for the gravel and tremie line. About 4 to 6 inches larger than the casing size is pretty common. If you are working shallow, say less than 100 feet, it is common to pour the gravel from the top. If you are much deeper, the gravel must be pumped through a tremie line. Usually the gravel is pumped with chlorinated, clear water to remove the filter cake and displace the drill mud. A lot of guys introduce the water/gravel slurry to the suction of a centrifugal pump, and pump it to the hole. This works well, but it eats pumps.

I once went on a job where the company sent two extra complete rebuild kits for the centrifugal pump. I asked what that was all about. They said, “You’ll need them.” Nothing like standing around in ankle deep water rebuilding a pump in winter. That got me thinking, so I designed and built a jet hopper system. I tied in the rig pump to pump the clear water. I sized the orifice in the jet for about 250 psi with my pump at idle. No more sand through the pump! It would take gravel almost as fast as my backhoe could load the hopper. Used that system on many jobs after that.

Once the gravel is in place, proper development is next, but this will have to be a topic for another day. A properly done gravel packed well is an amazing piece of engineering and will make all the water the formation will provide. I’ll write more about development another day. Keep ‘em turning to the right!

For more Wayne Nash columns, visit www.thedriller.com/wayne.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!