How Can Drilling Spoils Pass the Paint Filter Liquid Test?

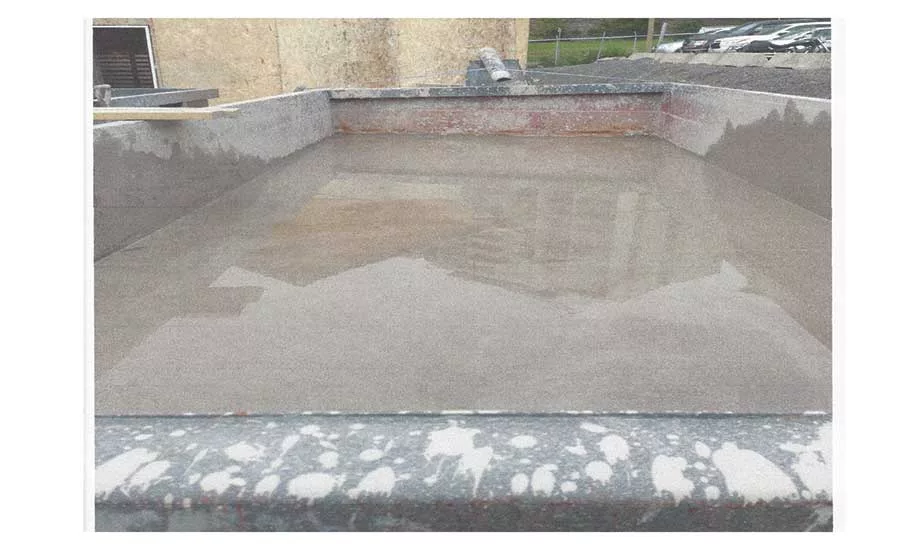

Getting the “wet” out of drilling spoils can significantly affect the cost of waste disposal. Source: CETCO Drilling Products photos

As a technical sales manager, I get asked with more and more frequency about problems associated with drilling spoils disposal. Most landfills will not take fluids. Now, we aren’t blaming the landfills — drill spoils containing free liquid can cause considerable damage to leachate collection and treatment systems, plus fluids can cause trucks and other equipment at the landfill to bog down. Additionally, most landfills consider the drilling fluids contaminated. Generally, the bentonite-based fluid wouldn’t be considered a hazardous product even with the additional additives and polymers needed in certain soil conditions. However, no one knows what the soil contains where the bore was done. Therefore, most landfills simply say no, or if they do have an area that accepts liquid they can charge as much as $1,300 for the dump!

This situation is not new, and we in the industry bump up against it several times a year. Some consider it a more “urban” area problem, but with increasing consistency I am hearing from contractors and distributors in rural areas as well. Most of us have run into this scenario several times. If not, consider yourself lucky, but chances are you will see it in the future.

Let me ask you a question: Have you ever been in a situation where you don’t have an agreeable facility to dump your liquid drilling spoils? What if you could just take your returns and, with very little time, effort and money, convert the liquid spoils into a solid waste, which would be acceptable to dump at the local landfill?

The key to this conversion from liquid to solid waste is a very simple test called the “paint filter liquid test” (PFLT). It is likely you’ve heard of a waste sample “passing/failing paint filter,” but what exactly is paint filter and what role does it play in waste determination? Paint filter is a U.S. EPA- approved test method (EPA 9095B) to determine the presence of free liquids in a representative sample of waste. How the test works is very simple. A predetermined amount of material is placed on a common conical 60 mesh paint filter. If any portion of the sample passes through and drops from the filter in a five minute period, then the material is deemed to contain free liquids. Paint filters are inexpensive and available from many local paint stores.

Choices for Contractors

There are options for getting drill spoils to pass a paint filter test.

The first option we will look at is centrifuge dewatering. In this system, we are separating the liquid from the solids in a mechanical fashion. Often, separation enhancement chemicals, such as coagulants and flocculants, are introduced into the drill spoils. These chemicals cause the solid particles to clump together, which aids in the separation process. The spoils are then fed into the decanting centrifuge that spins as high as 3,000 times the force of gravity, which separates the solid from the liquid.

This is a very efficient way to turn drill spoils into landfill disposable solids. These operations can produce crystal clear water at very high volumes. However, the equipment needed is very expensive to own or rent and, in most cases, trained operators are necessary to run the equipment. The costs involved will be prohibitive in most medium or smaller projects.

The second option is the solidification process, using various materials such as dirt, fly ash, lime or sawdust. These options have been used in the past to absorb free liquids, but they also add bulk and are labor intensive, which adds unwanted costs to the operation.

The third option also involves solidification, but it uses a newer polymer-based solidification process.

One such product available is a mixture of a non-biodegradable, powdered inorganic mineral and polymer. The mixture is used in the solidification of waste slurry that fails to pass a paint filter liquids test. This product can be poured into or across the surface of the waste slurry pit, stirred with a backhoe or excavator, or applied with soil mixing equipment. Depending on the solids content of the drill spoils, a small dosage of 2 percent by weight can be used. This will not add any significant bulk, so your landfill fees would not increase.

Another polymer-based solidification product is a granular, super-absorbent polymer that rapidly absorbs and retains aqueous matter. This polymer-only product is made from a non-biodegradable polymer also designed for use on waste slurry that fails to pass a paint filter liquids test. This type of polymer-only solidification product requires an average dosage of only 1 percent by weight. It can be mixed into the slurry waste pit with a backhoe or excavator and will not increase the volume of waste.

In addition to waste pit solidification, there are many drillers who have a bucket or two handy in case they have a spill on someone’s driveway or frack-out on a city street. The last thing you want is to wash the drill spoils or fluids down the storm sewer system. Not only is it bad form, but it can also carry severe fines and the possibility of being arrested. I would much rather be in a position to say we cleaned it up properly by solidifying and hauling off!

Depending on your situation, you may find yourself in need of getting the “wet” out of your drilling spoils and trying for a more solid situation. No matter what type of drilling you do — vertical, horizontal, urban or rural — you may run into this situation. There is a solution. Check local regulations, explore options and be sure to factor these disposal costs into your projects. Remember, it is much easier to dispose of drill spoils that pass the paint filter test!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!