Drilling Through History

Drilling has a long, storied history. Scroll down to see our timeline of drilling history, where we revisit the birth of important technologies and methods.

First American

spring-pole well

The first documented spring-pole well in America was drilled in 1806 by David and Joseph Ruffner in West Virginia. It reached 58 feet in depth, containing 40 feet of bedrock. The project lasted two years.

Read more 1806

America's first gas well

First natural gas well in the U.S. William Hart dug the well after noticing gas bubbles in a creek near Fredonia, N.Y.

Read more 1821

First four-legged derrick

A patent to L. Disbrow for the first four-legged derrick was given, originally in 1825 and then elaborated on in 1830. The structure consisted of legs made of square timber wood. The girts were mortised and inserted into the wooden legs with keys so the structure could be dismantled.

Photo source: California Historical Society / Creative Commons

America's first oil well

Men in Kentucky were drilling an exploratory well for salt brine. Instead, they hit an oil well. The pressure of the gas and oil underneath the surface forced an enormous geyser into the air. This was noted to be America’s first oil well (although there are some disputes to this claim).

Read more 1829

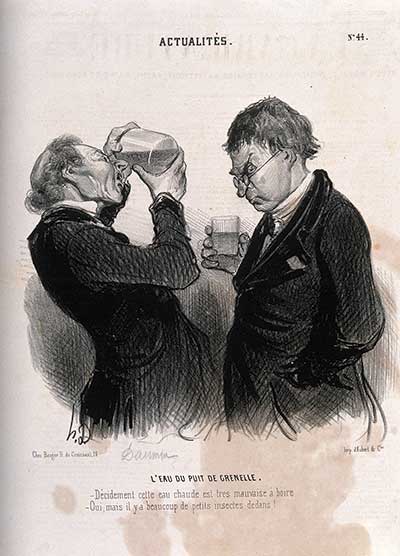

Grenelle Well

The Grenelle well in France was reached by a dry rotary auger method. It was drilled to 1,771 feet and took eight years.

Photo source: Wellcome Images / Creative Commons

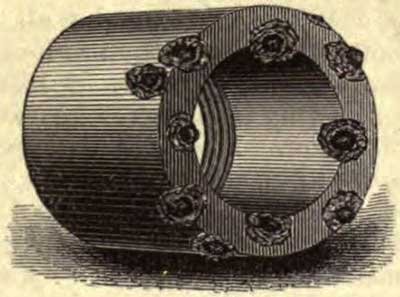

Drilling jars patented

William Morris, a spring pole driller in West Virginia, patented drilling jars.

Photo source: Creative Commons

Water circulation

used in drilling

The French engineer Pierre-Pascal Fauvelle was the first to utilize water circulation in drilling. Using the new method, he drilled 560 feet in 23 days.

Read more

Invention of the rotary drill

The first rotary drill was invented by Englishman Robert Beart.

Read more 1845

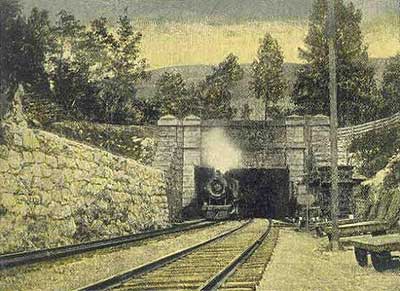

Invention of the

mechanical percussion drill

J.J. Couch invented the first mechanical percussion drill, which he later perfected with the help of fellow inventor J.W. Fowle. Steam was admitted alternately to each end of a cylinder. The drill was thrown like a lance at the rock on the forward stroke, caught and then drawn back on the reverse stroke, and then thrown again. It was the first drill that did not depend on gravity. It went to work on the Hoosac Tunnel project, which bored a passage for trains through hills near North Adams, Mass.

Photo source: Creative Commons

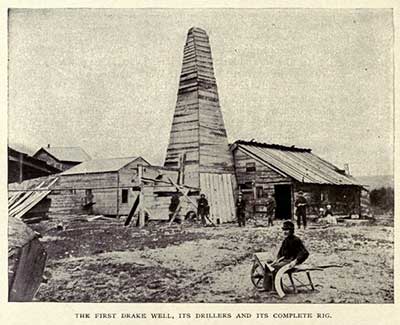

Drake Well

George Bissell and Edwin L. Drake made the first successful use of a drilling rig on a commercial well drilled especially to produce oil in Pennsylvania. They drilled to 69 feet.

Photo source: Public Domain

Steam-powered oil derrick

In June, J.C. Rathbone drilled a discovery well to 140 feet using a steam engine on the banks of the Great Kanawha River in the Charleston, W.Va., area. The well produced about 100 barrels of oil a day.

1860

Invention of the

diamond core drill

The diamond core drill was invented by Rodolphe Leschot, a French engineer. Leschot patented the device in the United States.

Photo source: Public Domain

Innovations in rotary drilling technology

Peter Sweeny, building on Robert Beart's earlier design, made a huge advancement in rotary drill technology, enabling almost continuous drilling. His new design also improved on hole cleaning.

Read more

Compressed air Burleigh drill

Charles Burleigh, John W. Brooks, and Stephen F. Gates patented a mechanical drill meant to be used on the Hoosac tunnel: the compressed air Burleigh drill. The tunnel spurred several innovations in drilling technology, including the earlier Couch/Fowle drill.

Photo source: Public Domain

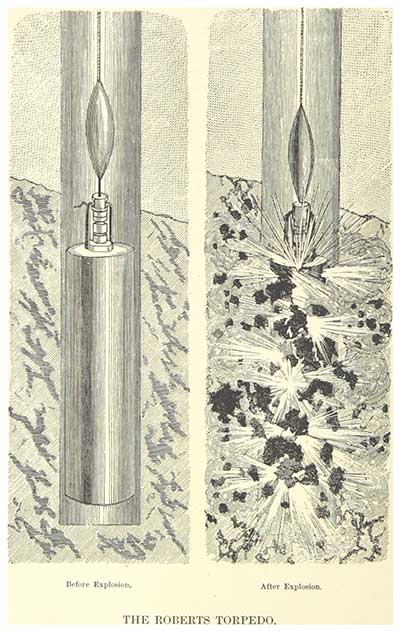

Roberts Torpedo

Edward A.L. Roberts was awarded a patent in November 1866 for what would become known as the Roberts Torpedo, a device for increasing the flow of oil by using an explosion deep in a well. The new technology revolutionized the young oil and natural gas industry by increasing production from individual wells.

Photo source: Public Domain

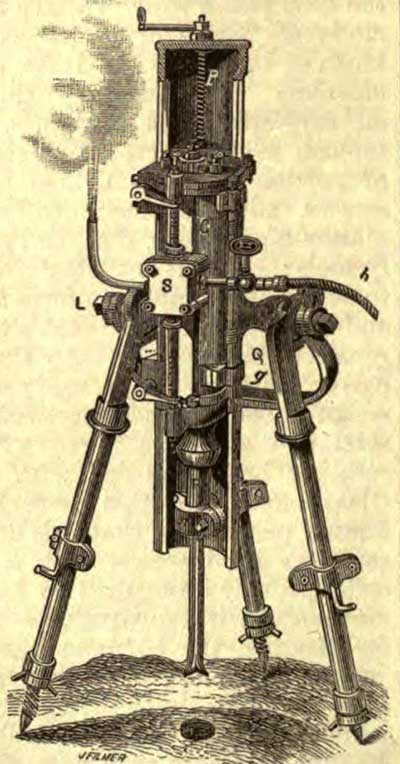

Ingersoll Rock Drill

Simon Ingersoll received a patent for a rock drill on a tripod mount. The drill was designed for mining and tunneling. It enabled the operator to drill at virtually any angle. He formed Ingersoll Rock Drill to capitalize on this invention, a company that is a precursor to Ingersoll-Rand.

Photo source: Public Domain

Diamond drill patented

John Vivian was given the first U.S. patent for a diamond drill. While other drills before its time bored holes through a succession of blows, this invention allowed the core to remain intact. This made it very valuable for prospectors.

Read more 1876

Bucyrus-Erie

The Bucyrus Foundry and Manufacturing Company was founded in Bucyrus, Ohio. The company later became famous in the drilling industry as Bucyrus-Erie, a maker of cable-tool rigs, but it was an early producer of steam shovels. It supplied many of the steam shovels used in the building of the Panama Canal.

Read more 1880

First well drilled with

rotary equipment

Brothers M.C. and C.E. Baker drilled the first well with rotary equipment. They pumped water with a windmill in Yankton, Dakota Territory.

Read more 1882

Sergeant Drill Company

Henry C. Sergeant started the Sergeant Drill Company to manufacture a rock drill he had invented, which included using compressed air to move the drill’s piston onto the steel in a hammering motion. Sergeant Drill Company later merged with Ingersoll Rock Drill to form Ingersoll-Sergeant Drill Company.

Read more 1884

First electric drill

Arthur James Arnot patented the world's first electric drill on Aug. 20. The new device was designed for rock drilling, primarily in coal mines.

Read more 1889

“Widow maker”

C. H. Shaw developed a stoper drill nicknamed the “widow maker.”

Read more

First diamond core hole

Edmund J. Longyear drilled the first diamond core hole in the Mesabi Iron Range (shown above in 1903) in northern Minnesota. Shortly thereafter, he formed a contract diamond drilling company to serve the rapidly growing U.S. iron ore mining and steel industry.

Photo source: Public Domain

Flexible shafts in drilling bits

John Smalley Campbell issued the first U.S. patent for the use of flexible shafts to rotate drilling bits. The patent was for dental applications, but was broad enough to cover larger scales, such as those used now in horizontal oil wells.

Read more 1891

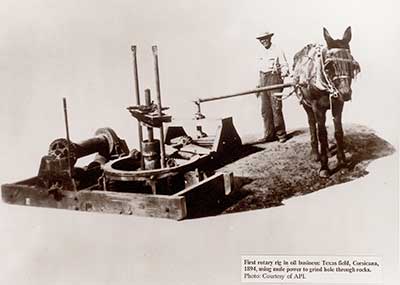

Rotary method used in

oil well drilling

The Baker brothers were using their rotary method for oil well drilling in the Corsicana field of Navarro County, Texas. Their rig was powered by a mule.

Photo source: Public Domain

Invention of water-cooled drill

John G. Leyner invented a water-cooled drill that helped dampen dust raised in drilling.

1897

First use of drilling mud

Drillers at Spindletop, including brothers Curt and Al Hamill and Peck Byrd, noticed that muddied-up freshwater could help stabilize a formation and prevent borehole collapse. They started circulating it and drilling mud was born.

Read more 1900

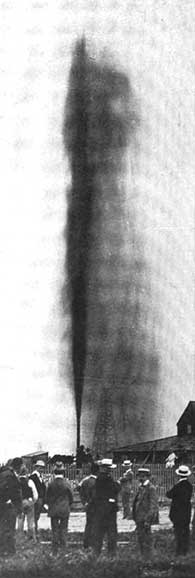

Spindletop oil gusher

Captain Anthony F. Lucas at Spindletop began drilling with a steam-driven rotary rig and a double-pronged fishtail bit. The gusher at Spindletop lasted nine days and ushered in the first Texas oil boom.

Photo source: Public Domain

Sharp-Hughes Tool Co.

Inspired by the success of Spindletop and what it meant for the future of oil drilling in Texas, Howard Hughes Sr. and Walter Sharp founded the Sharp-Hughes Tool Company. The Hughes name lives on today in the name of the company Baker-Hughes.

Photo source: Public Domain

Beginnings of Boart Longyear

Edmund J. Longyear and John E. Hodge formed Longyear & Hodge, the manufacturing partnership that would eventually evolve into Boart Longyear. The company's early drills were steam powered.

Read more 1903

"Rock Eater"

Howard Hughes Sr. and Walter Sharp introduced the Sharp-Hughes Rock Bit, which was nicknamed the "rock eater." It was suited for deep boring through medium and hard rock.

Read more 1909

Breakup of Standard Oil

The Supreme Court of the United States ruled that Standard Oil, which at the time controlled more than 90 percent of U.S. production, was a monopoly and that the company must be broken up to create competition in the market.

Read more 1911

Steel derrick patented

Lee C. Moore patented a system that clamped and secured bracing to steel pipe legs to build a steel derrick. At that time, oil derricks were commonly wooden cable tool rigs.

Read more 1912

Rotary table & kelly

The rotary table and kelly were first used. The primary function of the rotary table was to transmit torque to the drillstring via the kelly, a section of pipe with a square cross-section that slotted through a similar shape on the rotating table.

Read more

Core splitter

Hugh Roberts, working as a geologist for Edmund Longyear, designed a new form of technology called a core splitter, which divided cores into 3- – 5-inch lengths for better analysis. Drilling firms used Roberts's core splitter as standard equipment.

Read more 1915

Introduction of the sub

Hughes Tool Company (formerly the Sharp-Hughes Tool Company) introduced the sub, a large-diameter reamer placed above the bit designed to keep boreholes straight.

Read more 1917

Innovations to

the rotary table

Victor York and Walter G. Black of Standard Oil Company of California were granted a patent for driving the rotary table with a shaft. This innovation guaranteed the ongoing success of the rotary drilling method.

Photo source: Public Domain

Development of drilling fluid additives

Drillers began adding weighting materials like barite and iron oxide to drilling fluids, as well as mined bentonite clays.

Read more 1920s

Invention of the portable seismic rig

Portable percussion-type seismic rigs were invented.

Read more 1920

First geothermal power plant

John D. Grant drilled a geothermal well to power the world's first geothermal power plant in California. The plant provided electricity to light a resort called The Geysers.

Read more 1921

Development of

detachable drill bit

Arthur L. Hawkesworth of the Anaconda Copper Mining Company developed the first extensively-used detachable rock drill bit.

Read more 1922

Diesel power

The rotary drilling method was improved with the use of diesel power.

1925

First horizontal oil well

The first true horizontal oil well was drilled near Texon, Texas. By the early 1980s, with advancements in drilling motors and steering, the technology finally became widespread.

Meredithw / English Wikipedia

First portable rotary rig

George E. Failing introduced the first portable rotary rig to the industry. The idea first came after he mounted an existing rig on a 1927 Ford farm truck, adding a power take-off assembly to transfer power from the truck engine to the drill. The new portable rotary rig could drill ten 50-foot-deep holes in a day.

Photo source: Cherokee Strip Regional Heritage Center

Beginnings of Baroid

Cal Talc, A. J. Lynch and National Pigment Chemical merged to form Baroid Sales Company. The new company, founded to serve the growing market for products for hydraulic rotary drilling, is based in Los Angeles.

Read more 1930

Invention of the Marsh funnel

Harlen Marsh of General Petroleum Company invented the funnel that carries his name. He donated the concept for the device, which measures relative viscosity of drilling fluid, to the drilling industry.

Read more 1931

Tricone drilling bit patented

The Hughes Tool company was granted a U.S. patent for the tricone drilling bit.

Photo source: Public Domain

Introduction of the cantilever drilling mast

Lee C. Moore, known for the standard derrick, introduced a cantilever-type drilling mast.

Read more 1937

Increased capacity

in irrigation wells

Reverse circulation was adapted for use in drilling large-diameter irrigation wells. These higher capacity wells allowed farms to thrive.

Photo source: Public Domain

Portable CFA drill produced

Mobile Drilling produced its first portable continuous flight auger (CFA) drill.

Read more 1949

Tricone drilling bits entered general market

The Hughes Tool Company's patent on the tricone drilling bit expired, setting off a flurry of activity as competitors entered the market.

Read more 1951

World's deepest cable-tool well

In June, the New York State Natural Gas Corporation abandoned a project after having drilled the world's deepest cable-tool well to a depth of 11,145 feet. The well was located in Van Etten, N.Y. The project started five years earlier.

Read more

Invention of the wireline core retrieval system

Longyear applied for a patent for the first wireline core retrieval system.

Read more 1953

First downhole drilling motors

The first downhole drilling motors, or mud motors, were designed and manufactured by Dyna-Drill. The motor was based on the 1930 Moineau design for progressive cavity pumps.

Photo source: Joshua Doubek / Wikimedia Commons

Sheppton Mine disaster

A Bucyrus-Erie 50-R was instrumental to the rescue of two miners who survived the Sheppton, Pa., mining disaster.

Read more 1963

Introduction of

Compax, PDC bits

General Electric Research Lab (GE) introduced a new synthetic material made of diamond grains sintered together with cobalt. This new material, Compax, could be made into various shapes and retained diamond’s natural property of extreme hardness, but not its weak cleavage planes. To make a cutter, a thin layer of the synthetic diamond material was deposited onto a disk-shaped tungsten carbide substrate so that the assembly, called a “compact,” could be attached to the bit. Bits with this kind of cutter are generically called PDC bits.

Photo source: Geolina163 / Wikimedia Commons

Mud pulse telemetry introduced

Teleco Oilfield Services Inc., together with the U.S. Department of Energy, introduced mud pulse telemetry, now a widely used method of transmitting measurement while drilling data to the surface. Commercialized in 1978, the technology had been under development since the late 1960s. Data transmitted by pulses, together with trigonometry, can give operators a three-dimensional plot of the well being drilled. Pulse telemetry improved on the slower process of wireline logging. Teleco was later acquired by Baker Hughes.

Read more 1978

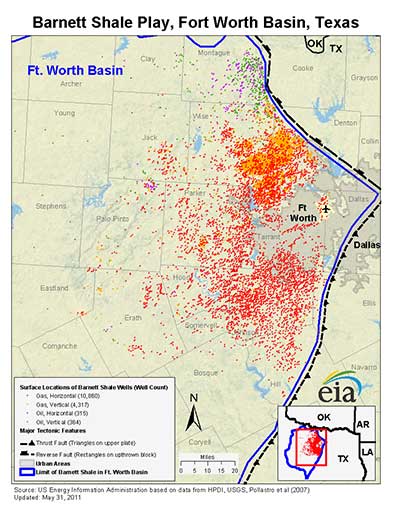

Start of hydraulic fracturing

George P. Mitchell of Mitchell Energy & Development Corp. began experimenting with hydraulic fracturing in horizontal wells in the Barnett Shale near Fort Worth.

Photo source: U.S. Energy Information Administration

Beginnings of sonic drilling

The Versa-Sonic drill rig was put into operation. Versa-Drill International Inc. and Bowser-Morner built this rig that incorporated Ray Roussy’s new sonic drill head. Roussy had worked to improve and perfect the technology over more than 20 years from original designs, which modified oscillators for drilling purposes. Sonic drills, like this one used by the Army Corps of Engineers, are now widely used for sampling.

Photo source: U.S. Army Corps of Engineers Sacramento District

“Zipper fracking”

Professors at Texas Tech University developed “zipper fracking,” which is when operators drill two wells side by side. The process allowed both wells to produce more oil and gas.

Read more 2012

Deeper wells drilled faster

Advancements in drilling technology moved rapidly in five years, as 16,000-foot wells were taking an average of 32 days to drill. By 2013, the average drill time for 21,000-foot wells was 18 days or less.

Photo source: Joshua Doubek / Wikimedia Commons

Dig deeper into the drilling and water supply industry!

Build your knowledge with The Driller, covering the people, equipment and technologies across drilling markets.

SIGN UP NOWCopyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing